Method and device for preparing gallic acid

A technology of gallic acid and tannic acid, which is applied in biochemical equipment and methods, methods for supporting/immobilizing microorganisms, and biochemical cleaning devices, etc., can solve the problems of many side reactions, darkening of crude product color, and long production cycle, etc. Achieve the effect of adapting to large-scale production, reducing production costs and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The method for preparing gallic acid of the present embodiment comprises the following steps:

[0029] (1) Preparation of immobilized tannase

[0030] a. Carrier soaking: Put the carrier LX-1000HA resin in the carrier pretreatment tank with agitator, add deionized water (just submerge the resin on the water surface) for soaking, add NaOH solution with a concentration of 2mol / L to adjust the soaking liquid The pH is 8, and the soaking water is discharged after soaking for 1.5 hours;

[0031] b. glutaraldehyde crosslinking: add K to the carrier pretreatment tank described in step a 2 HPO 4 , glutaraldehyde and deionized water, so that the mass fraction ratio of the material in the pretreatment tank is: carrier LX-1000HA resin: K 2 HPO 4 : glutaraldehyde: deionized water=10:0.4:1.0:88.6. And adding a NaOH solution with a concentration of 2mol / L to adjust the pH to 7.8 and stirring at a stirring speed of 100r / min, after stirring for 1 hour, take out the LX-1000HA resin...

Embodiment 2-6

[0039]The operating steps of Examples 2-6 are the same as those of Example 1. The glutaraldehyde crosslinking process conditions in step (1) and the immobilization conditions of tannase are shown in Table 1. The tannic acid in step (2) See Table 2 for the process conditions of enzymatic hydrolysis and the conversion rate of tannic acid.

[0040]

[0041] Step (2) In the process of preparing gallic acid by tannic acid enzymatic method, the immobilized tannase added is prepared according to Example 2 in step (1), and other process condition parameters are shown in Table 2, and the rest are the same as in Example 1 。

[0042]

Embodiment 8

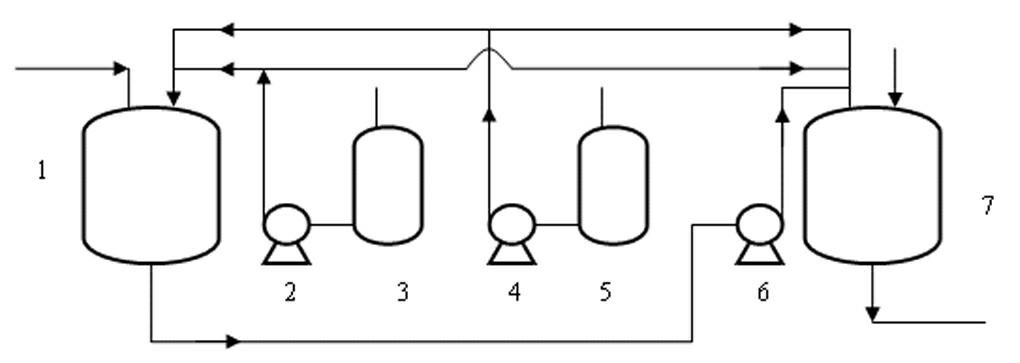

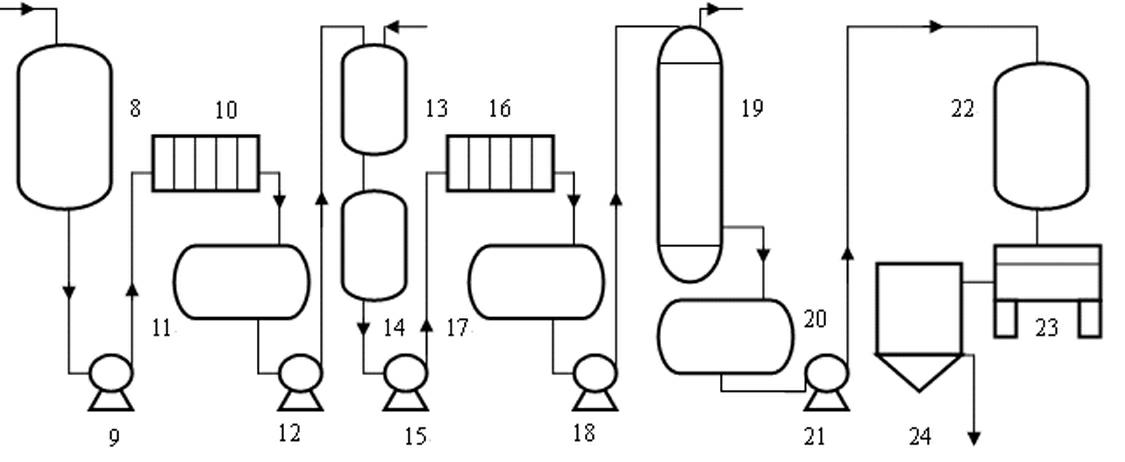

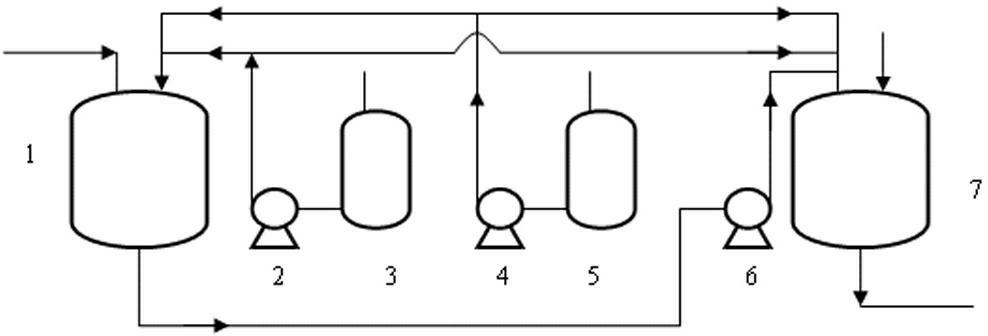

[0044] With reference to the accompanying drawings, the device for preparing gallic acid in this embodiment includes a tannase immobilization device and a gallic acid preparation device, and the tannase immobilization device includes a carrier pretreatment tank 1, a feed pump I2, Storage tank I3, feeding pump II4, storage tank II5, feeding pump III6, immobilization tank 7, heating and cooling system (not shown in the figure), storage tank I3 is connected with carrier pretreatment tank 1 and The immobilization tank 7 is connected, the storage tank II5 is connected with the carrier pretreatment tank 1 and the immobilization tank 7 through the feed pump II4, the carrier pretreatment tank 1 is connected with the immobilization tank 7 through the feed pump III6, and the carrier pretreatment tank 1, immobilization tank 7 is connected with heating and cooling system; The preparation device of described gallic acid comprises raw material extraction tank 8, feeding pump IV 9, filter pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com