Pit-sealing method of pit pool for solid brewing

A solid-state brewing and cellar technology, which is applied in the field of wine making, can solve the problems of reduced fermented grains capacity, cellar pollution, and high-quality cellar sealing mud becoming rough, so as to improve water retention performance, avoid bacterial contamination, and ensure normal fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Embodiment Adopt the method of the present invention to seal cellar

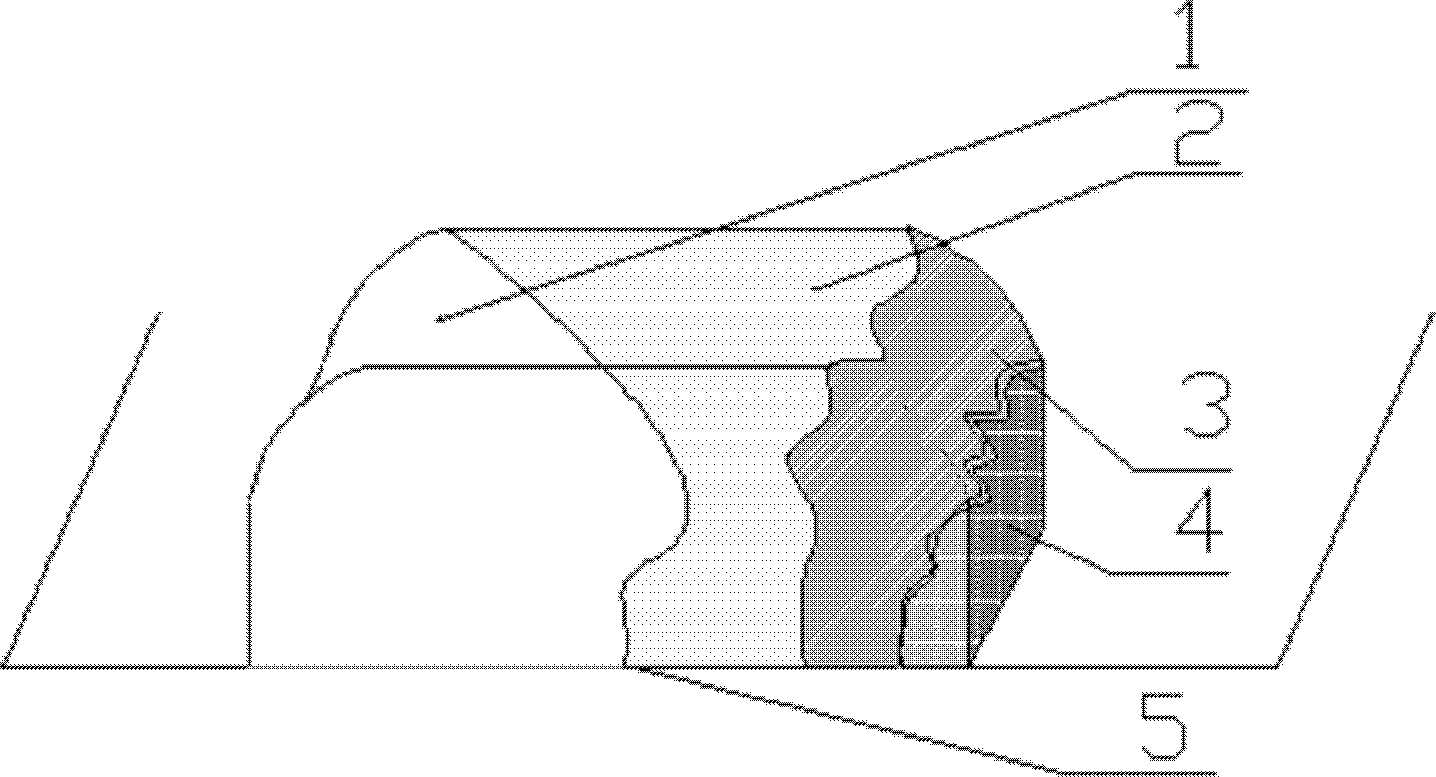

[0028] Such as figure 1 As shown, a layer of old Fengjiao mud 3 with a thickness of 8 to 15 cm is covered on the pit pit 4, and then a layer of yellow mud layer 2 with a thickness of 0.1 to 1 cm is applied on the Laofeng pit mud 3, and it is smoothed and wiped with a trowel. Light. The yellow mud to be applied is made of fine fresh yellow soil without impurities, soaked in hot water at 80°C and stirred continuously, so that the soil can fully absorb water and form a cohesive yellow mud colloid. This yellow mud is applied on the old seal pit mud to form the yellow mud layer 2. After the mud sealing cellar was completed, the cellar pool 5 was closed with plastic film 1 immediately, and the edge of plastic film 1 was inserted in the cellar sealing mud 3 edge, and stepped on firmly with foot, thereby tightly sealed cellar pool.

[0029] The results show that there are no air leaks and cracks on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com