Low-temperature type wood-plastic floor and preparation technology thereof

A technology of wood-plastic floor and preparation process, which is applied in the direction of architecture, building structure, floor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

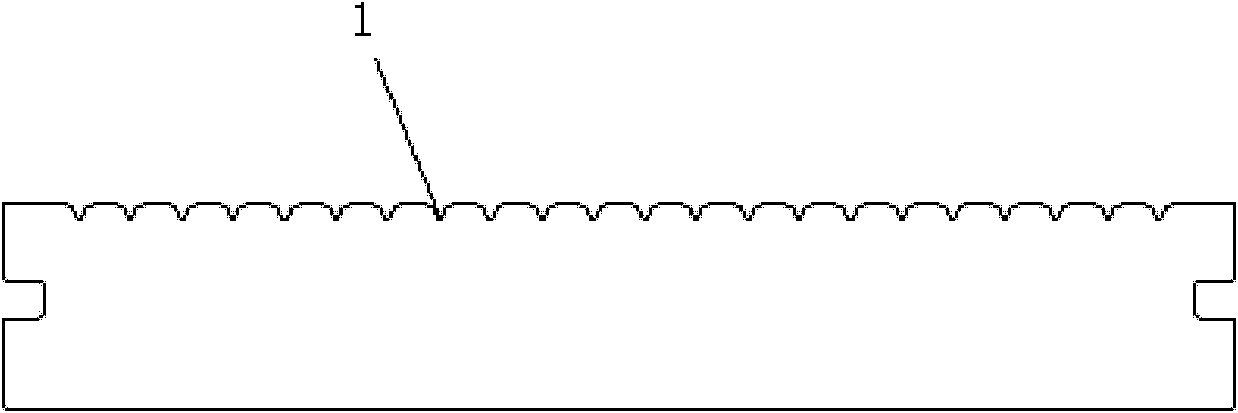

Image

Examples

Embodiment 1

[0033] Take the following raw materials by weight

[0034]

[0035] The specific preparation is carried out according to the following steps:

[0036] High-speed mixing and dehumidification process:

[0037] The various materials in the above formula are put into a high-speed mixer with a rotating speed of 650-1300RPM and mixed, the mixing time is 10-20 minutes, the dehumidification temperature is 140°C, and the dehumidification time is 10 minutes;

[0038] Granulation mixing process:

[0039] A 75-type co-rotating parallel twin-screw granulator was used, the granulation temperature was controlled at 120-210 degrees Celsius, and the current was 140-150 amperes.

[0040] Die extrusion molding process:

[0041] Use 65 or 90 type conical twin-screw profile extruder, the temperature is 120-200 ℃, the temperature of each section of the main screw is 120, 130, 140, 150, 170, 180 degrees, and the temperature of the confluence core and die is 180 °, the screw speed is 18 rpm, a...

Embodiment 2

[0044]

[0045] The specific preparation method is the same as that in Example 1.

[0046] The (-34°C to 60°C) linear expansion coefficients and mechanical properties of Examples 1 and 2 are as follows

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com