Automatic sand willow planting machine

A technology of planting machine and Salix salix, applied in forestry, application, agriculture, etc., can solve the problems of unguaranteed operation quality, soil vegetation damage, high labor intensity, etc., and achieve the effect of consistent plant distance, smooth coverage, and uniform compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

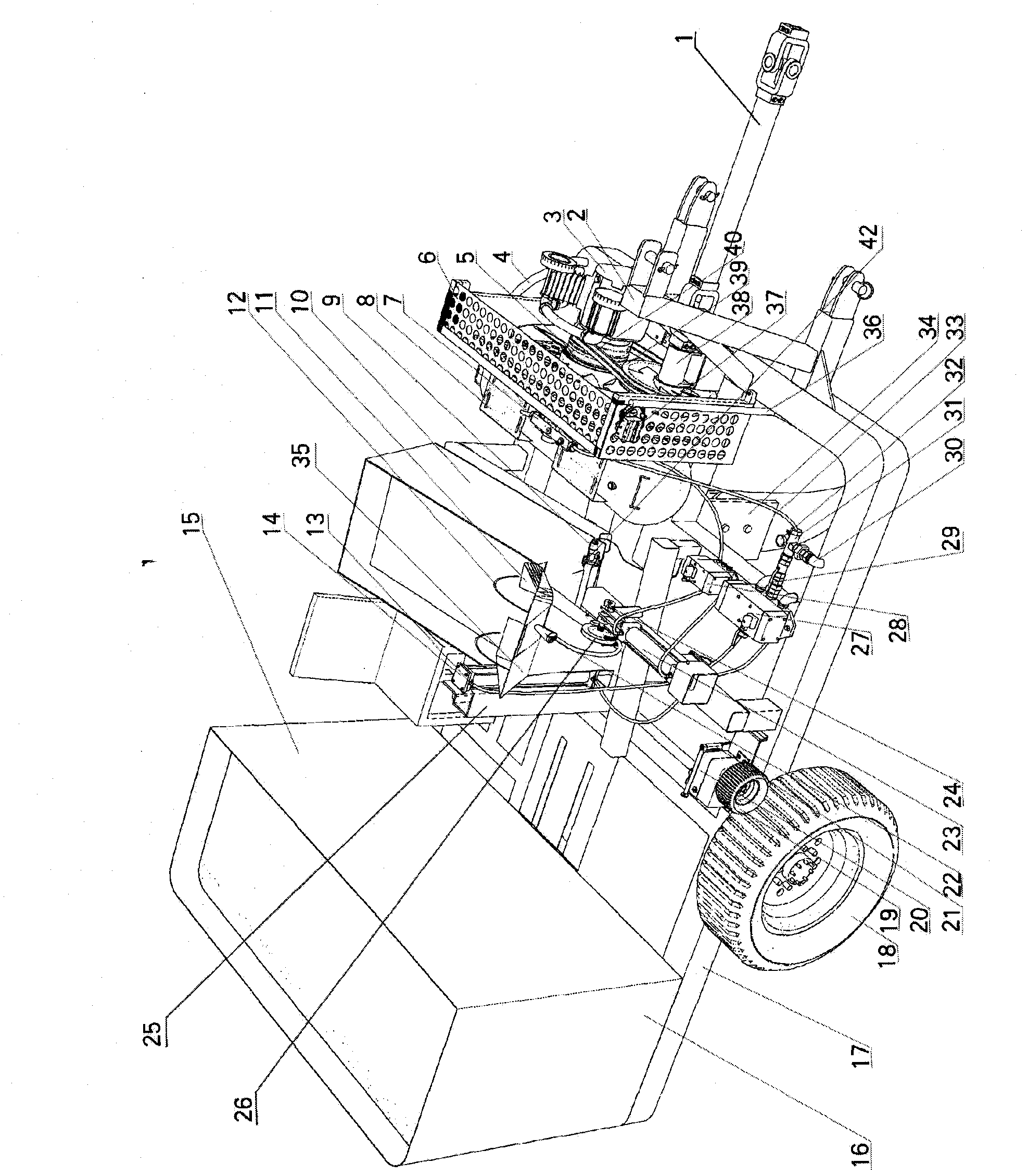

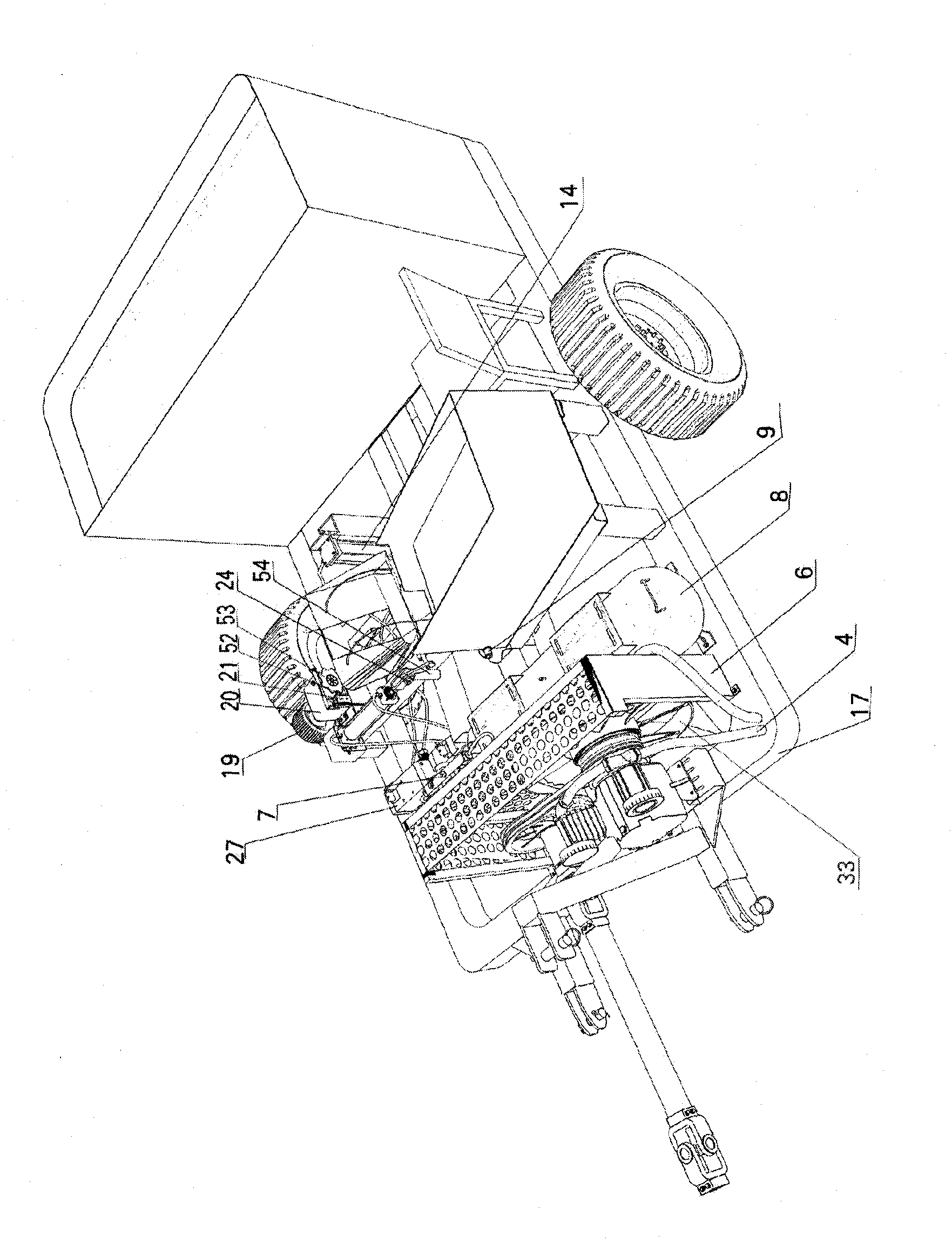

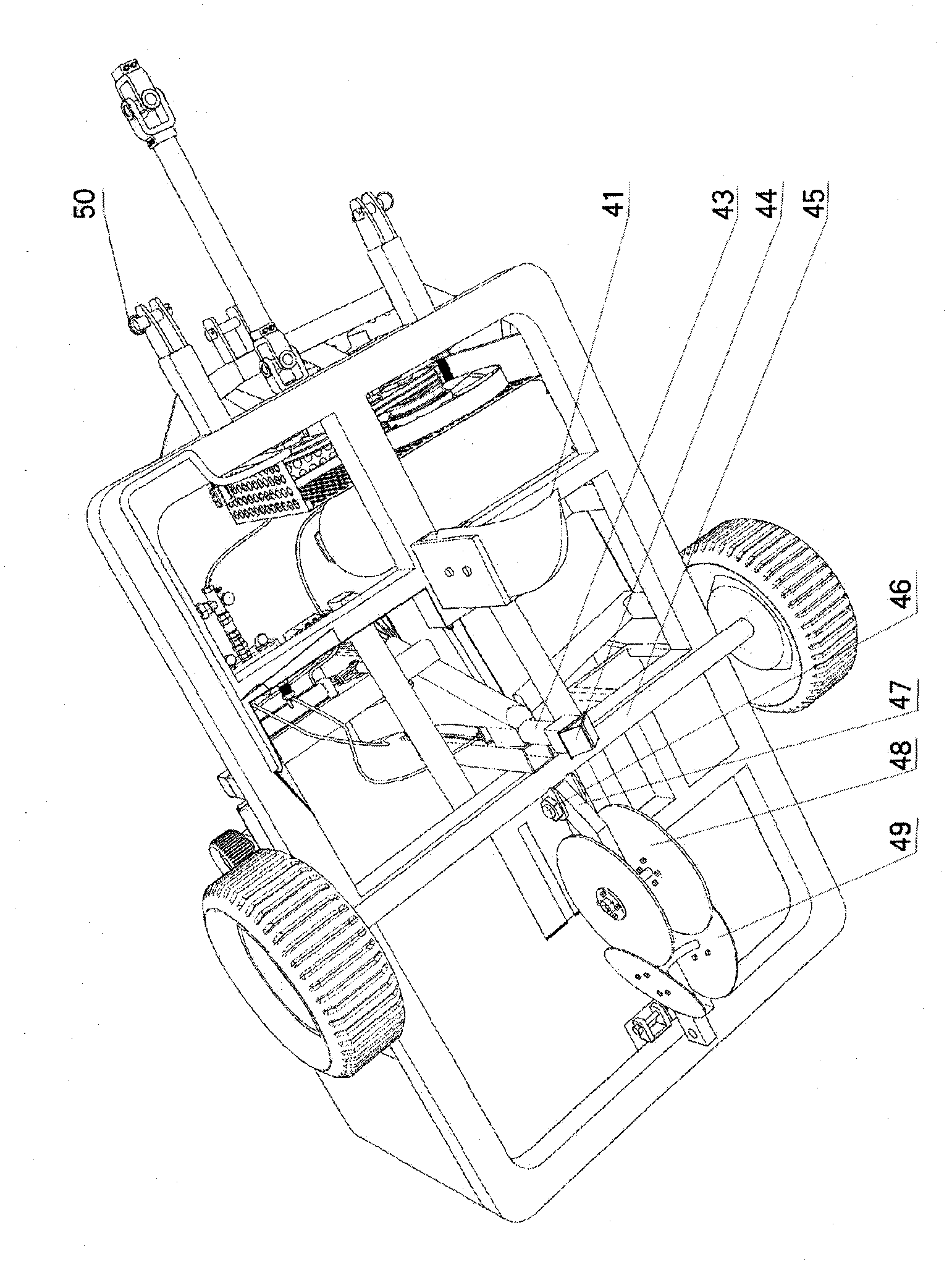

[0015] Automatic salix planter, including rectangular frame 17, three-point suspension traction frame 2, air compressor 3, cutting cylinder 14, grab cylinder 23, stepless gearbox 20, first solenoid valve 27, second solenoid valve 28 , cooling fan 33, walking wheel assembly 18, three-point suspension traction frame 2 is fixed on the rectangular frame 17, and base plate 16 is housed on the rectangular frame 17, and the upper end in the three-point suspension traction frame 2 is a universal power input shaft 1. The walking wheel assembly 18 is installed under the rectangular frame 17, and its characteristics are: the rectangular frame 17 is a sealed pipe, there are two front and rear beams on the rectangular frame 17, and one end of the universal power input shaft 1 passes through the bearing seat 38 It is connected with the front end of the rectangular frame 17, and the other end is connected with the power output shaft of the tractor. The shaft of the large pulley 39 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com