Method and device for drying a fibrous web

A fibrous web, drying technology, applied to the machine of cardboard web or tissue paper web, to manufacture fibrous web, to achieve the effect of reducing energy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

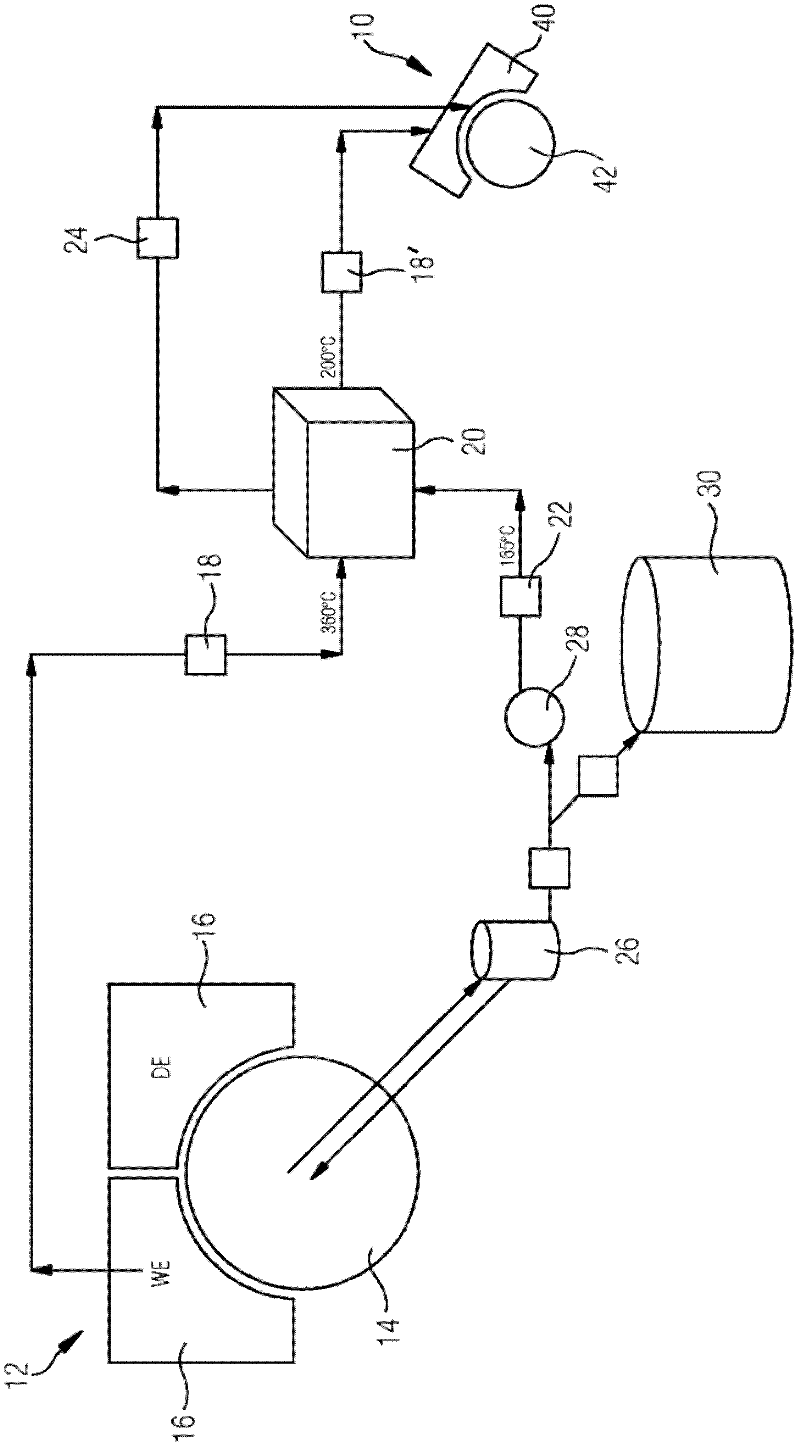

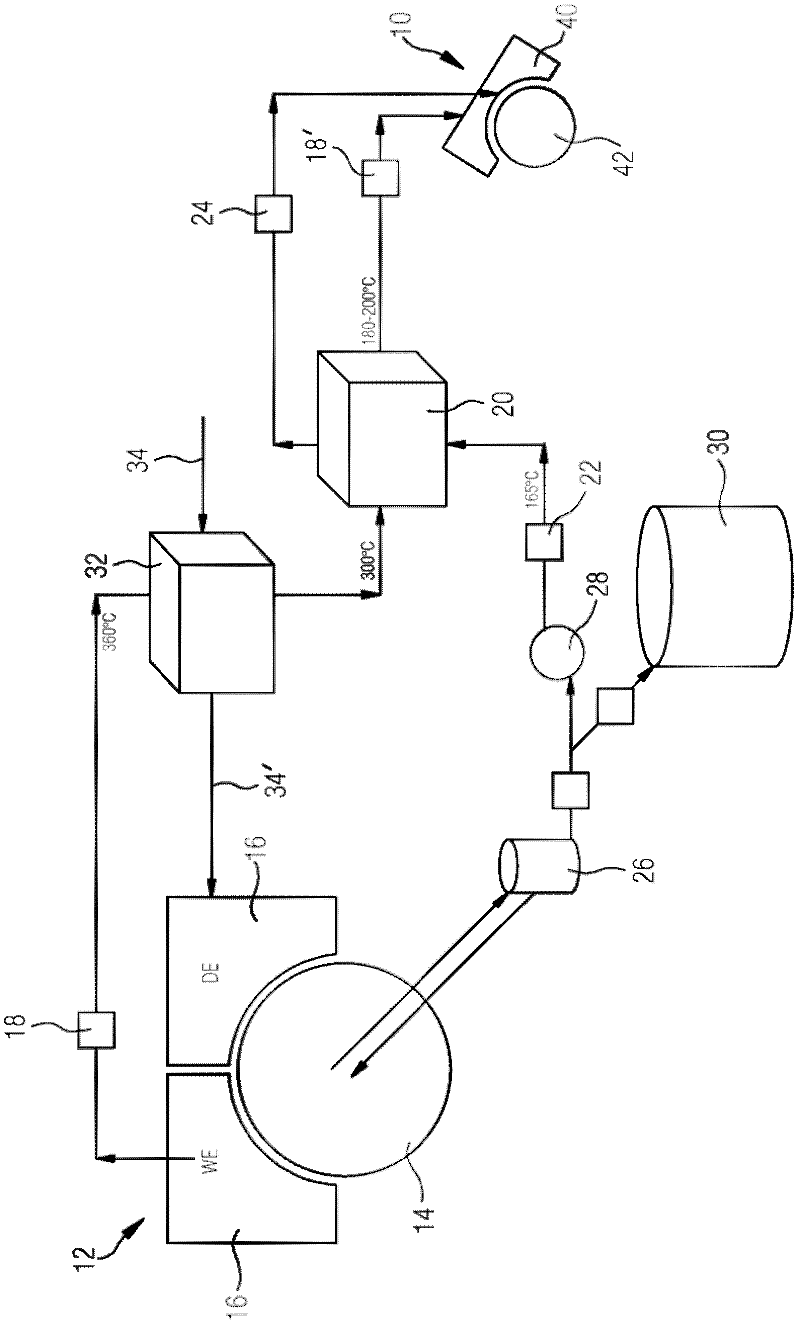

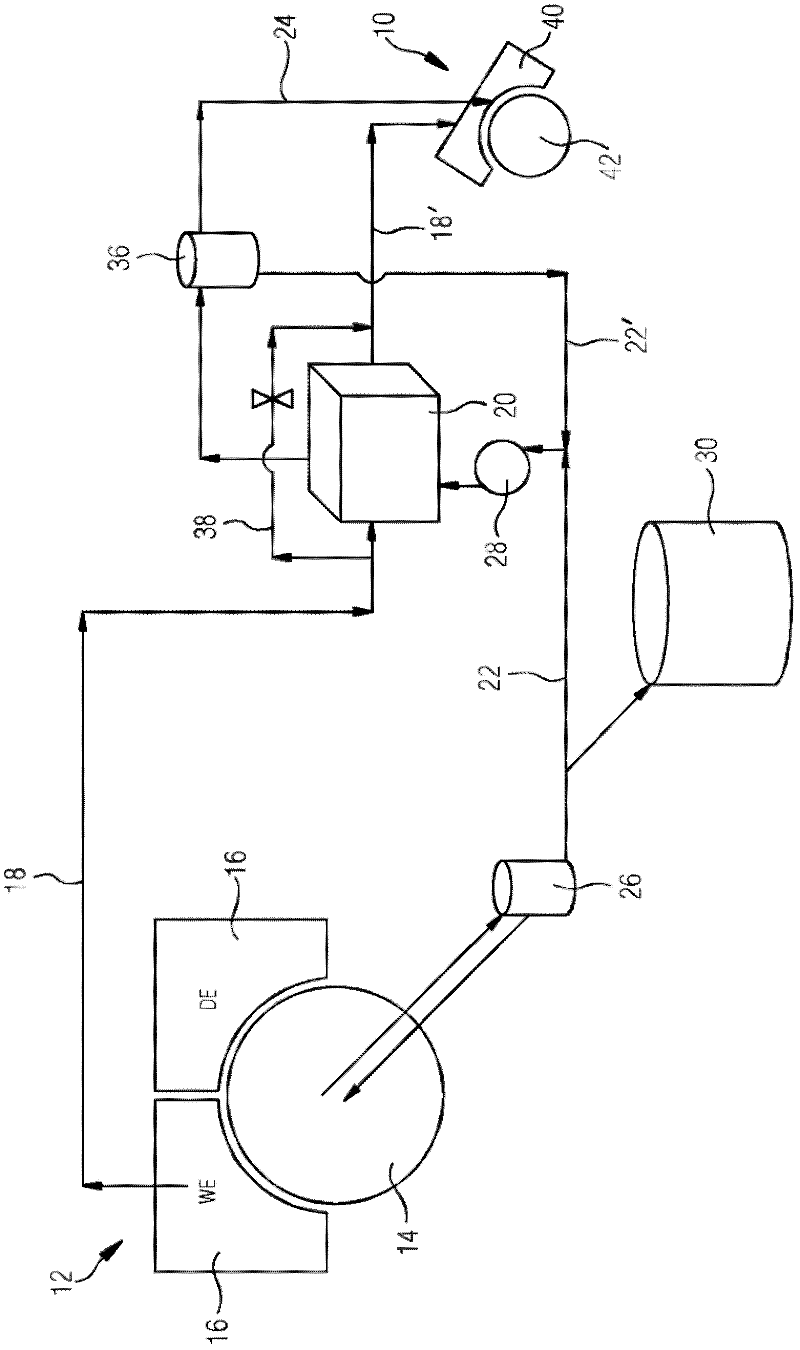

[0034] figure 1 Shows a schematic flow diagram of a first exemplary embodiment of a heat recovery system according to the invention of a machine for producing a fiber web, wherein the fiber web can be, in particular, a cardboard web, a paper web or a tissue paper width.

[0035] In this case, the continuous fibrous web is initially subjected to steam and hot, moist air in the area of the preceding drying zone 10 . The fibrous web is then conveyed into a post-drying zone 12 .

[0036] The preceding drying zone 10 here comprises in particular a suction device 42 , preferably a suction roll, through which the fiber web is guided together with at least one permeable belt, in particular a structured belt or a through-air drying belt. A roll in which steam or hot moist air flows first through a permeable belt and then through a fibrous web.

[0037]Furthermore, the fibrous web can be covered by at least one other permeable belt, especially a press belt, wherein, in this case, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com