Reusable thermistor overcurrent protection device and application in battery module

A technology of overcurrent protection and thermistor, applied in the direction of current response resistors, battery components, circuits, etc., can solve the problem of low safety factor of large-capacity battery modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

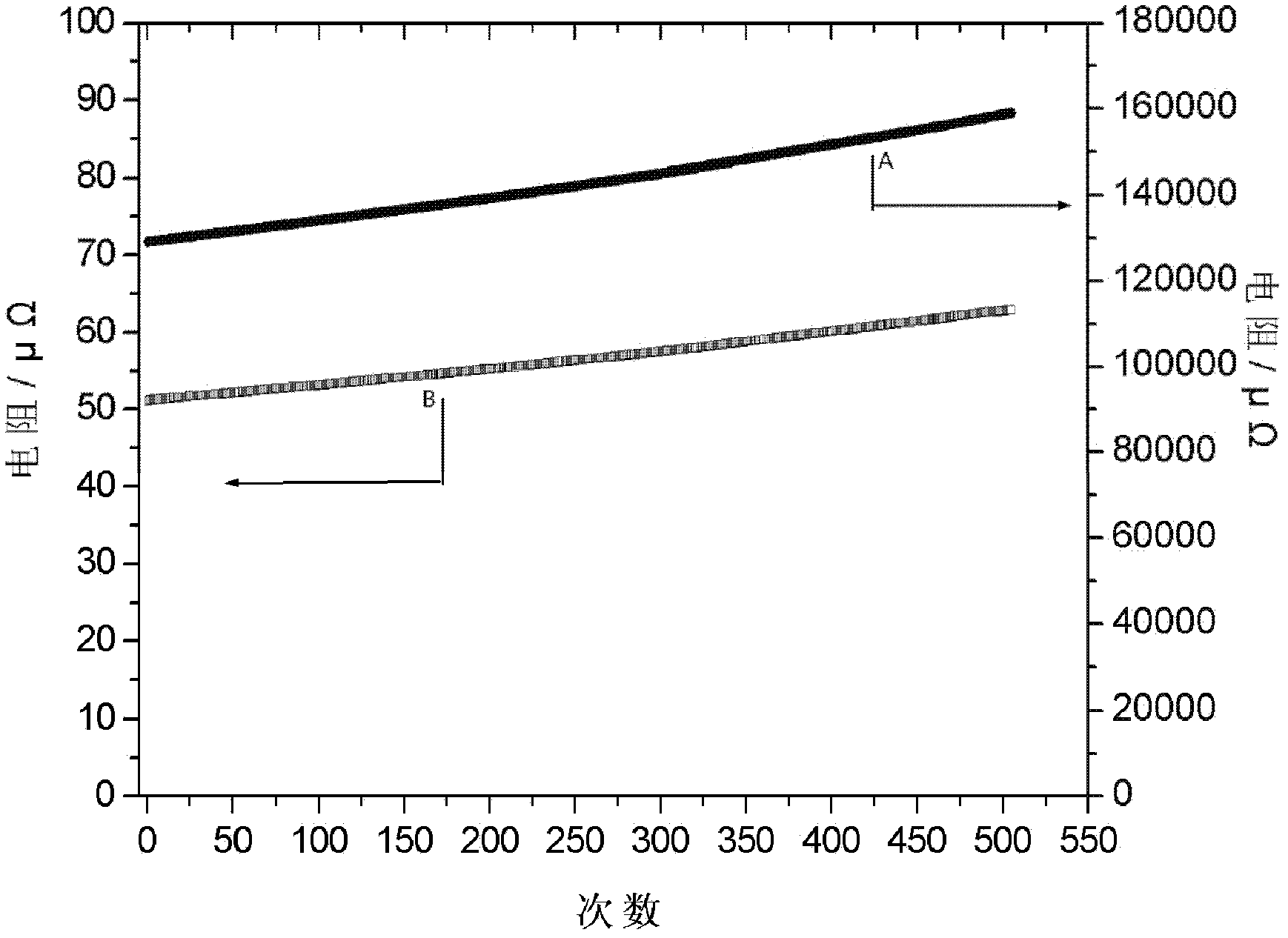

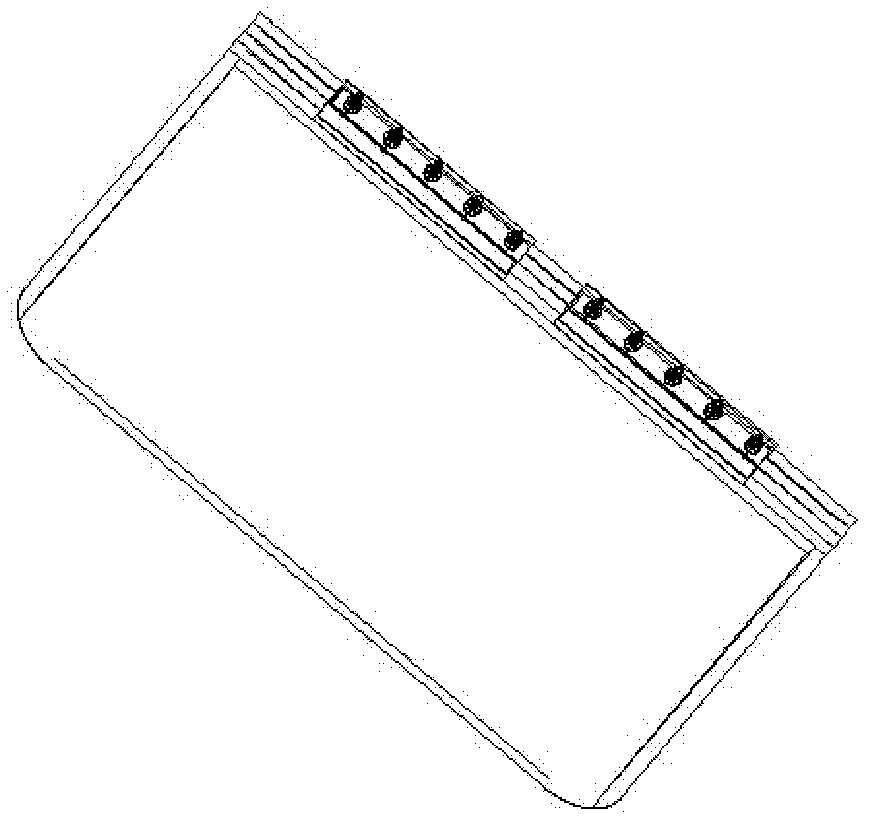

[0021] Example 1: figure 1 It is a schematic diagram of the structure of the busbar device with the function and characteristics of the thermistor, such as figure 1 As shown in the embodiment, the device includes:

[0022] Two copper plates, upper plate A and lower plate B, each with a thickness of 2.5mm, polymer PTC film with a thickness of 0.3mm, a Curie temperature of 85°C, and a lift-to-drag ratio of not less than 10 4 , provided by Shanghai Kete Co., Ltd. Plates A and B, PTC film have 2 threaded through holes. The shape of the upper and lower plates is 20*250*2.5mm (W*L*H), the shape of the PTC film is 20*250*0.3mm (W*L*H), and the hole diameter of the corner thread is 4mm.

[0023] The polymeric PTC film is placed between two metal plates, and the two plates are aligned with the four sides of the PTC film and the four holes. Keep the position fixed, place it on the lower plate of the hot press, and set two press travel positioning blocks on the plate of the hot press...

Embodiment 2

[0026] Two copper plates, upper plate A and lower plate B, each with a thickness of 3mm, polymer PTC film with a thickness of 0.3mm, a Curie temperature of 90°C, and a lift-to-drag ratio of not less than 10 4 , provided by Shanghai Kete Co., Ltd. Plates A and B, PTC film have 4 threaded through holes. The shape of the upper plate is 100*100*3mm (W*L*H), the shape of the PTC film is 100*100*0.3mm (W*L*H), and the diameter of the threaded hole is 6mm.

[0027] The polymeric PTC film is placed between two metal plates, and the two plates are aligned with the four sides of the PTC film and the four holes. Keep the position fixed, place it on the lower plate of the hot press, and set two press stroke positioning blocks on the plate of the hot press, so that the overall thickness of the three-layer composite is not less than 6.25mm after the press is pressed. Heat to 125°C on a hot press, and set the pressure to 3500Pa. After the temperature is reached, start to pressurize and ke...

Embodiment 3

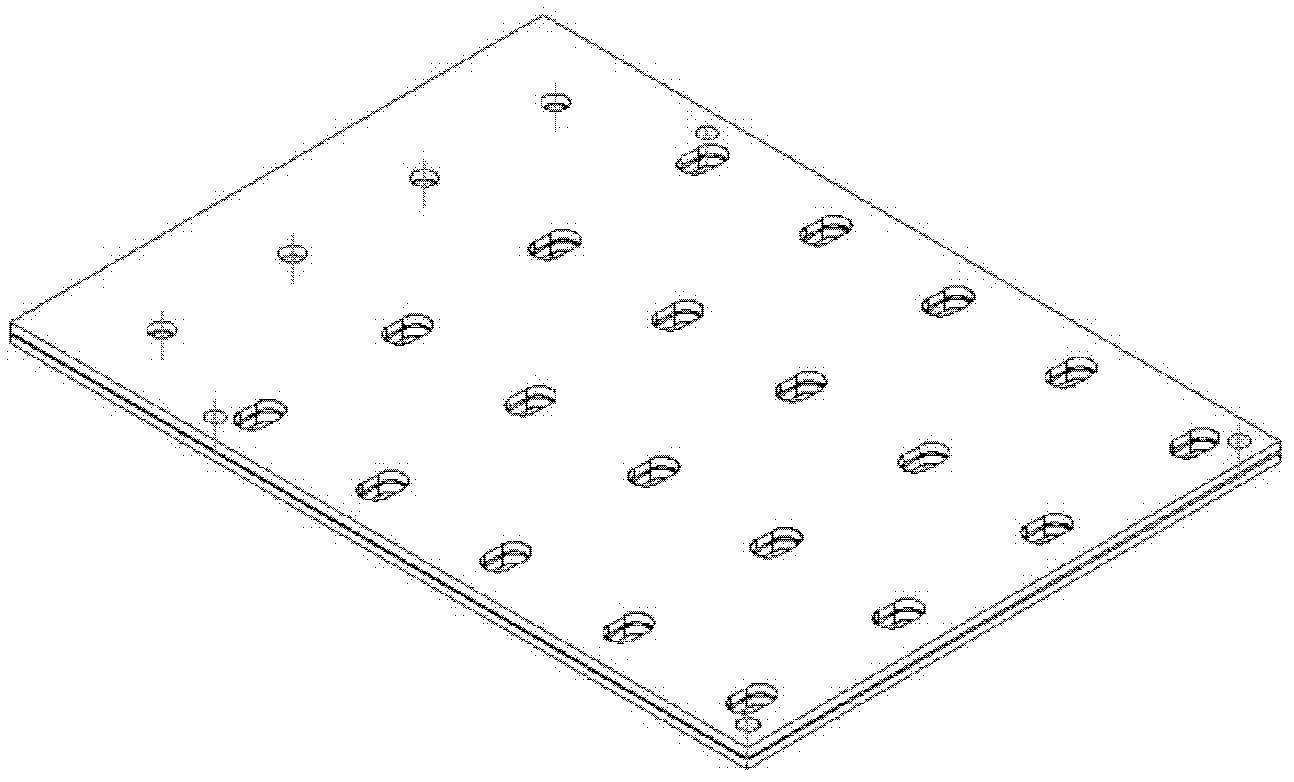

[0030] Two copper plates, upper plate A and lower plate B, each with a thickness of 4mm, polymer PTC film with a thickness of 0.3mm, a Curie temperature of 85°C, and a lift-to-drag ratio of not less than 10 4 , provided by Shanghai Kete Co., Ltd. Plates A and B, PTC film have 4 threaded through holes and have 20 12 diameter through holes. The shape of the upper and lower plates is 300*300*4mm (W*L*H), the shape of the PTC film is 300*300*0.3mm (W*L*H), and the diameter of the threaded hole is 8mm.

[0031] The polymeric PTC film is placed between two metal plates, and the two plates are aligned with the four sides of the PTC film and the four holes. Keep the position fixed, place it on the lower plate of the hot press, and set two press travel positioning blocks on the plate of the hot press, so that the overall thickness of the three-layer composite is not less than 8.25mm after the press is pressed. Heat to 135°C on a hot press, and set the pressure to 4000Pa. After the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com