Armored cable preheated-type cold rotary forging device and forging method thereof

An armored cable, rotary forging technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems that the shape and size cannot fully meet the design requirements, the dimensional accuracy of the parts does not meet the design requirements, and the production efficiency is affected. The effect of machining dimensions, reducing stress and strain, and improving tolerance levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

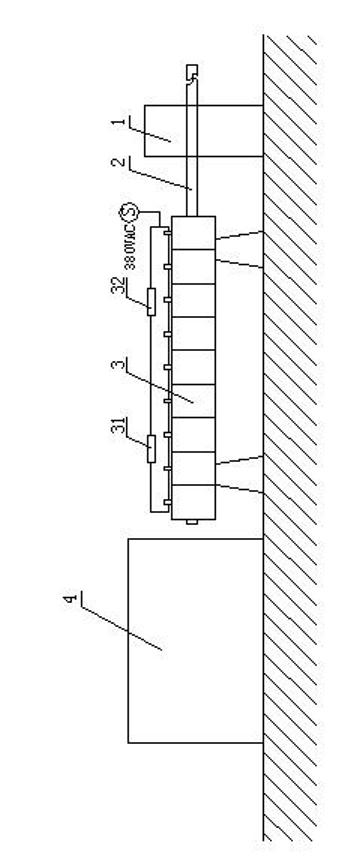

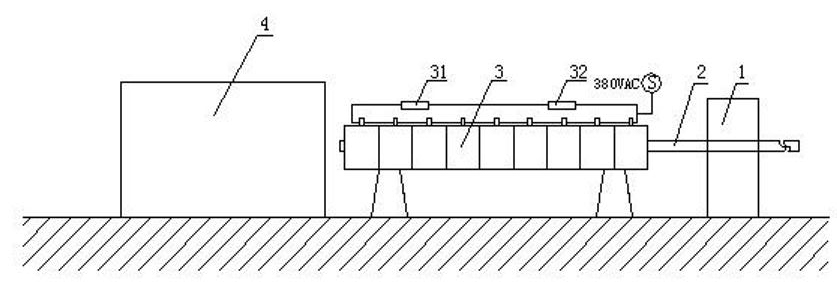

[0027] see figure 1 , a preheating type cold rotary forging device for armored cables, comprising a variable diameter swaging machine 4, the variable diameter swaging machine 4 is provided with a clamping feeding device 1, and the main frame of the variable diameter swaging machine 4 and the clamping feeding device 1 is provided with cylindrical temperature controllable heater 3.

[0028] The cylindrical temperature-controllable heater 3 is provided with a temperature controller 31 and a power regulator 32 .

[0029] A method for performing armored cable preheating type cold rotary forging with the above-mentioned armored cable preheating type cold rotary forging device, comprising the following steps:

[0030] a), Straightening

[0031] Straighten the armored cable 2 before rotary swaging;

[0032] b), clamping

[0033] Fix the straightened armored cable 2 on the clamping feeding device 1 of the variable diameter swaging machine 4, and adjust the feeding length;

[0034]...

Embodiment 2

[0041] see figure 1 , a method for carrying out armored cable preheating type cold rotary forging with the above-mentioned armored cable preheating type cold rotary forging device, comprising the following steps:

[0042] a), Straightening

[0043] Straighten the armored cable 2 before rotary swaging;

[0044] b), clamping

[0045] Fix the straightened armored cable 2 on the clamping feeding device 1 of the variable diameter swaging machine 4, and adjust the feeding length;

[0046] c), feeding

[0047] Start the clamping and feeding device 4, so that the workpiece of the armored cable 2 is placed on the axis of the cylindrical temperature-controllable heater 3;

[0048] d), heating

[0049] Start the heating equipment to heat the armored cable 2 to a temperature of 500±5°C;

[0050] e), rotary forging

[0051] The heated armored cable 2 is swaged on a variable-diameter swaging machine 4 at the holding temperature until the swaging is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com