Low-pressure detector for waterproofness of thin waterproof coiled material

A waterproof membrane, water permeability technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of power consumption, high requirements for testing personnel, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

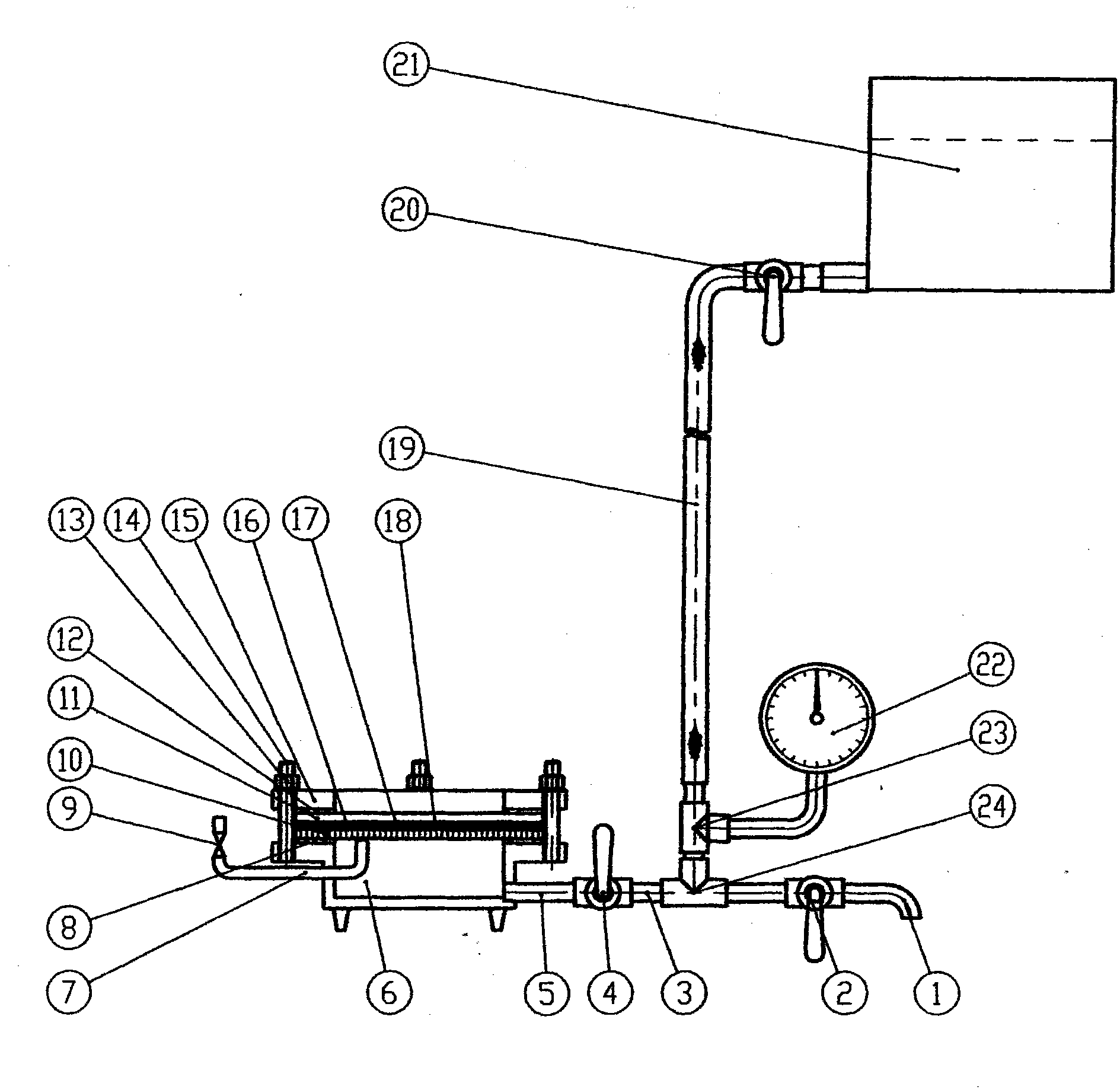

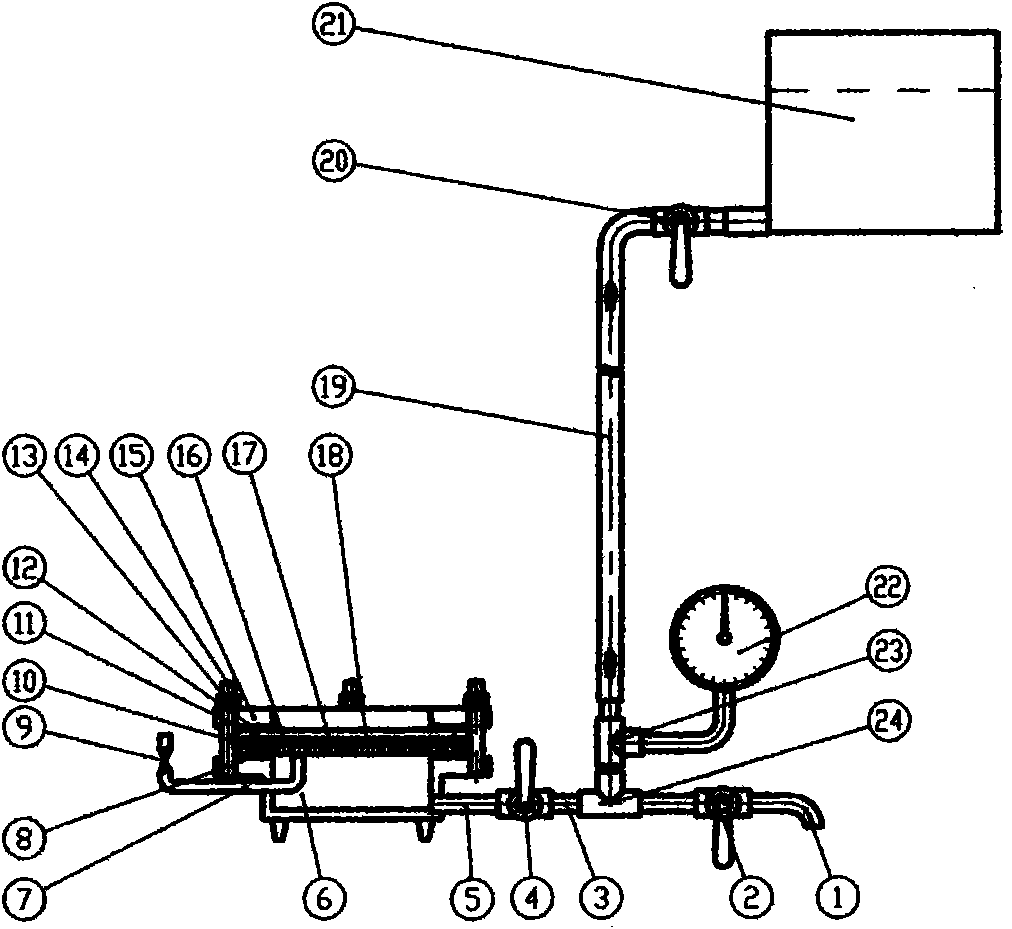

[0009] The low pressure tester for water impermeability of thin waterproof coiled material of the present invention comprises a water tank 21, a pressure gauge 22, a circular pressure base 6, an upper pressure flange 15, an exhaust valve 9, and a leather tube 19. The volume of the water tank 21 is greater than three times of the volume of the circular pressure base 6 . There is an exhaust pipe 7 passing through the upper part of the wall of the circular pressure base 6. The exhaust pipe 7 is externally connected to the exhaust valve 9, and the inside extends into the cavity of the circular pressure base 6, and its opening is located at a slightly lower position on the upper edge of the circular pressure base 6. . Several pressure screw rods 14 are installed on the top of the outer wall of the circular pressure base 6 . Between the circular pressure base 6 and the upper pressure flange 15, a lower rubber sealing gasket 8, a thin waterproof membrane test piece 10, a lower labor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com