Full honeycomb board wind power generator wind wheel blade

A technology for wind turbines and wind rotor blades, which is applied to wind turbine components, wind engines, and wind power generation, and can solve the problem of releasing harmful gases, difficulty in the shape of wind rotor blades, and impossibility of popularizing honeycomb wind turbine blades And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

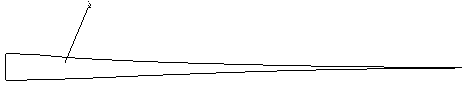

[0057] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the full honeycomb plate wind rotor blade of the present invention includes a shell and an internal support structure. The shell is mainly composed of an upper half shell and a lower half shell. The internal support structure is placed in the shell and connected with the upper half shell and the lower half shell. The supporting parts of the half-shells are respectively connected, wherein the upper half-shell is formed by bending the first honeycomb plate 1, the lower half-shell is formed by bending the second honeycomb plate 2, the internal support structure is the longitudinal support plate 3, and the longitudinal support plate is formed by the vertical honeycomb plate Formed, the longitudinal support plate 3 and the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com