Preparation method for silver tin oxide electrical contact material

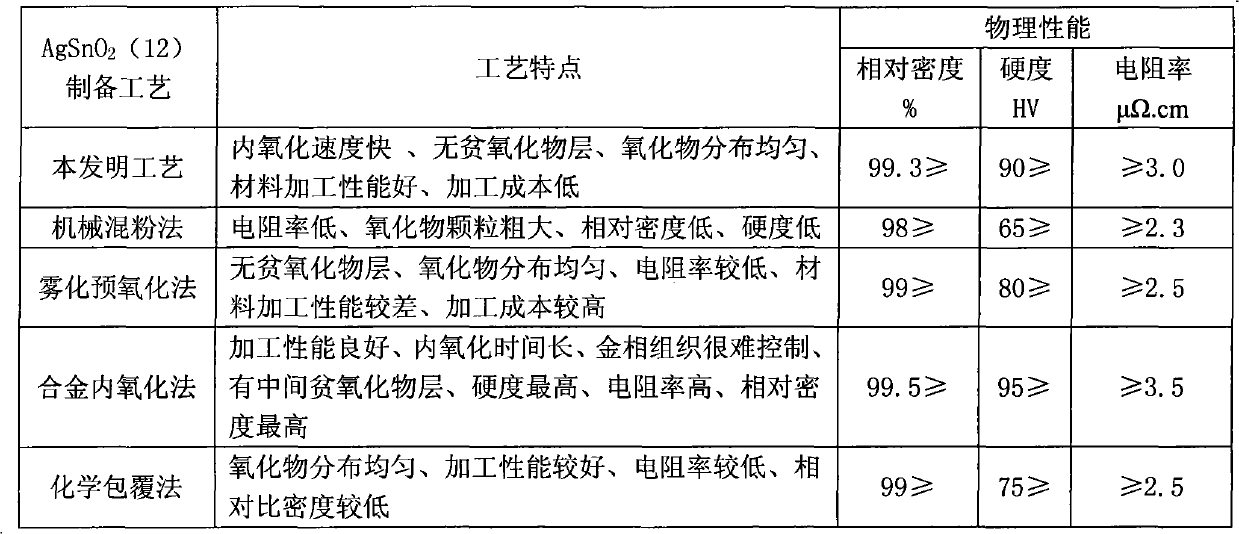

A technology of electrical contact materials, silver tin oxide, applied in the direction of contacts, circuits, electric switches, etc., can solve the problems of poor material processing performance, low density of contact materials, long internal oxidation time, etc., to ensure consistency, process Improved performance and uniform and stable contact composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] AgSnO 2 (8) In2O3(4) material preparation as an example

[0036] 1. Put 17.6kg of silver ingot in an intermediate frequency heating furnace, heat it to 1100°C-1200°C until Ag is completely melted, then cool down to 1000°C, add 1.26kg of tin ingot and 0.662kg of indium ingot, after melting, refine 10 minute;

[0037] 2. Under the air pressure of 8±1MPa, gas atomization powder making;

[0038] 3. AgSnIn alloy powder is made into ingot under 150MPa isostatic pressure;

[0039] 4. The AgSnIn alloy powder ingot was sintered in a hydrogen furnace for 4 hours at a temperature of 680°C;

[0040] 5. The AgSnIn alloy powder ingot is extruded on a 1100t extruder to prepare an AgSnIn alloy powder plate with a cross-sectional specification of 40X4mm;

[0041] 6. The AgSnIn alloy powder sheet is prepared by hot-rolling and silver-coating process into AgSnIn / Ag sheet with silver layer;

[0042] 7. The AgSnIn / Ag plate is cold-rolled and punched to prepare square sheet products;

...

Embodiment 2

[0046] AgSnO 2 (14)In 2 o 3 (1) Material preparation as an example

[0047] 1. Put 17kg of silver ingot in an intermediate frequency heating furnace, heat it to 1100°C-1200°C until Ag is completely melted, then cool down to 1000°C, add 2.207kg of tin ingot and 0.0.179kg of indium ingot, after melting, refine 10 minute;

[0048] 2. Under the pressure of 40±2MPa atomized water, atomize and make powder;

[0049] 3. AgSnIn alloy powder is made into ingot under 150MPa isostatic pressure;

[0050] 4. The AgSnIn alloy powder ingot was sintered in a hydrogen furnace for 4 hours at a temperature of 680°C;

[0051] 5. The AgSnIn alloy powder ingot is extruded on a 1100t extruder to prepare an AgSnIn alloy powder plate with a cross-sectional specification of 30X5mm;

[0052] 6. The AgSnIn alloy powder sheet is prepared by hot-rolling and silver-coating process into AgSnIn / Ag sheet with silver layer;

[0053] 7. The AgSnIn / Ag plate is cold-rolled and punched to prepare square sheet...

Embodiment 3

[0057] AgSnO 2 (12) Bi 2 o 3 (0.5) Material preparation as an example

[0058] 1. Put 17.5kg of silver ingot in an intermediate frequency heating furnace, heat it to 1100°C-1200°C until Ag is completely melted, then cool down to 1000°C, add 1.89kg of tin ingot and 0.090kg of bismuth ingot, after melting, refine 10 minute;

[0059] 2. Under the pressure of 40±2MPa atomized water, atomize and make powder;

[0060] 3. AgSn alloy powder is made into ingot under 150MPa isostatic pressure;

[0061] 4. The AgSn alloy powder ingot was sintered in a hydrogen furnace for 4 hours at a temperature of 680°C;

[0062] 5. AgSn alloy powder ingots are extruded on a 1100t extrusion machine to prepare AgSn alloy powder materials with a cross-sectional specification of Φ6.0;

[0063] 6. After the AgSn alloy fan material is drawn to Φ2.0, it is placed in an internal oxidation furnace for internal oxidation. The internal oxidation process is: internal oxidation into AgSnO at a temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com