Secondary mixer for coal spraying with blast furnace

A technology of secondary mixing and blast furnace coal injection, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as uneven mixing, reduce the number of blockages, eliminate pulsation, and uniformly inject dense phases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

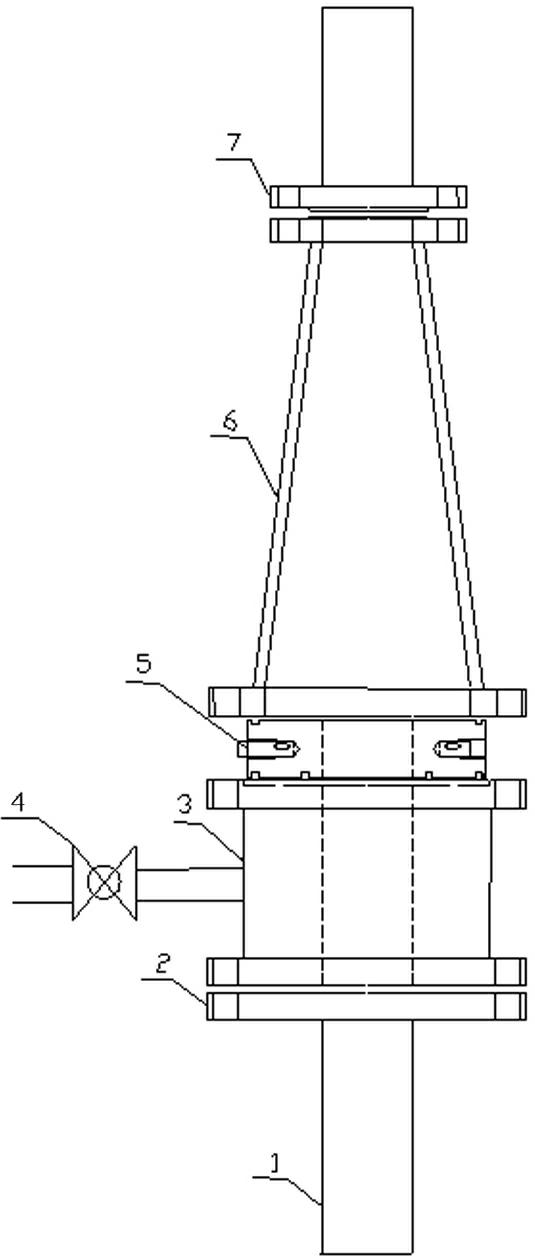

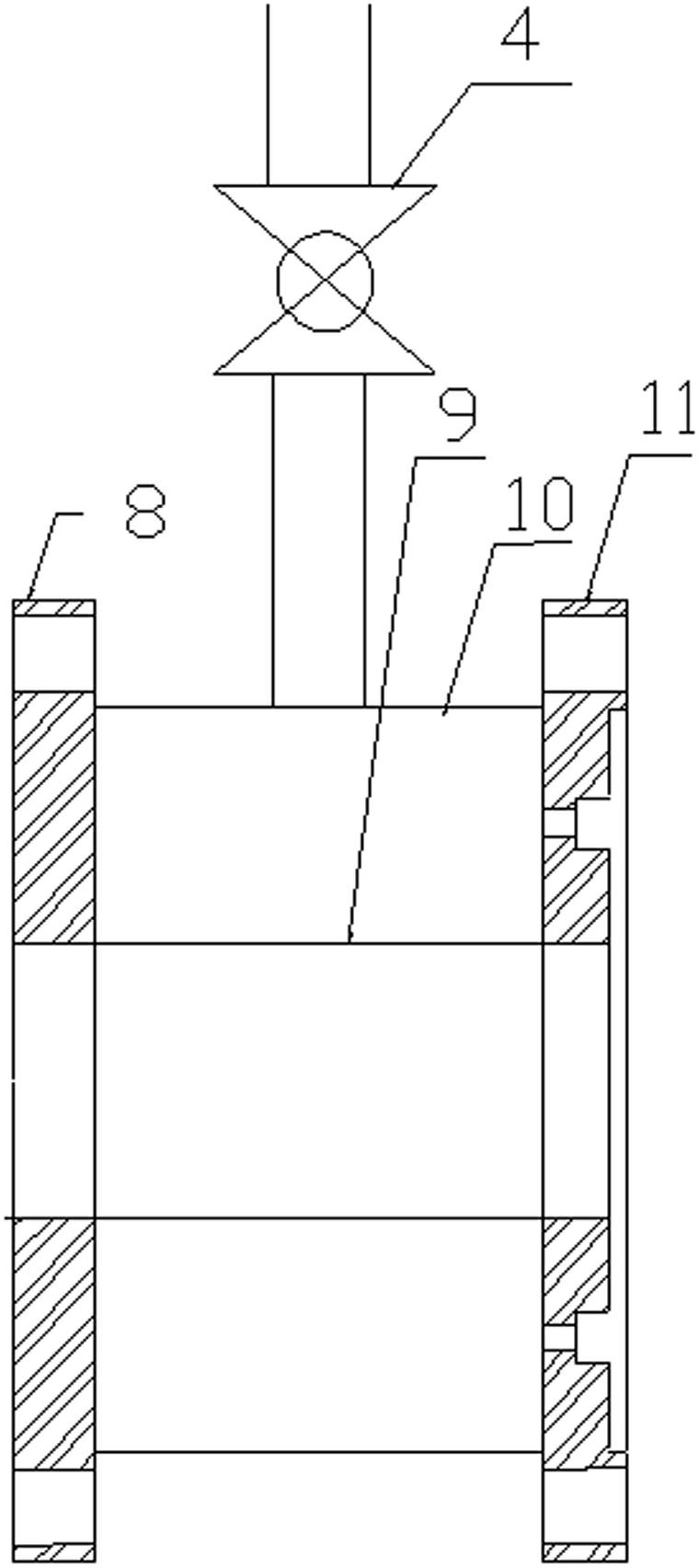

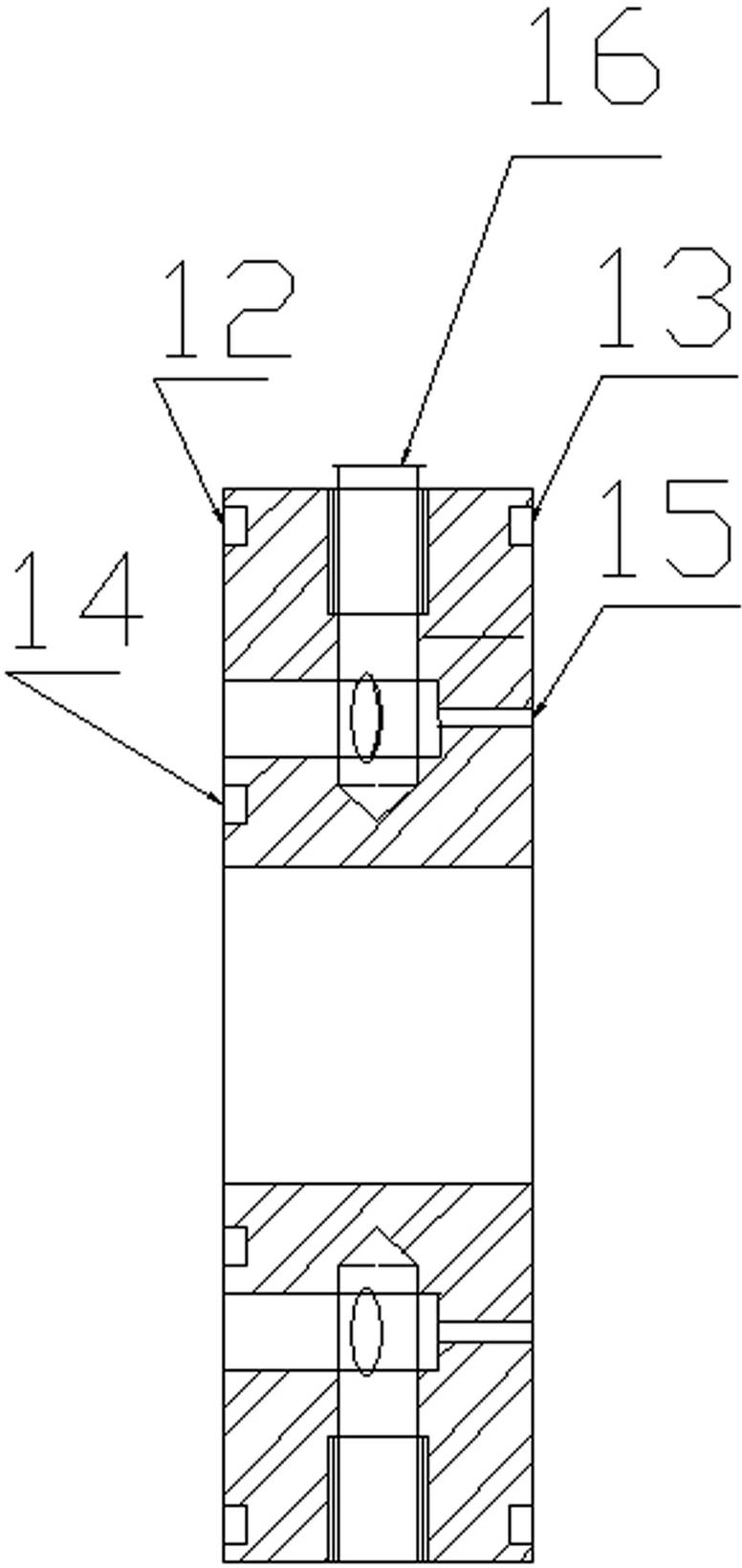

[0019] Describe in detail below in conjunction with accompanying drawing.

[0020] as the picture shows:

[0021] The gas double-layer pipe connector 3 is a double-layer pipe structure, the inner pipe 9 is a pulverized coal passage, the outer pipe 10 is a gas passage, and the outer pipe 9 communicates with the gas pipeline; one end of the gas double-layer pipe connector 3 passes through the flange 8 and The flange 2 at the inlet end of the coal injection main pipeline 1 is connected, and the other end is connected to the mixer core 5 through the flange 11. There is a mixing tank in the middle of the flange 11, and a hole in the mixing tank communicates with the gas source;

[0022] The mixer core 5 is a cylindrical hollow casting body, with sealing grooves 12, 13, 14 on both sides of the casting body, and O-shaped sealing rings are installed to connect with the flanges on both sides; the casting body is radially symmetrical with two mixed gas through holes 15 , a mixed air ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com