Four-in pump

A technology of coupled pumps and pistons, applied in the field of quadruple pumps, can solve problems such as pulsation and severe vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention will be described below with reference to the drawings.

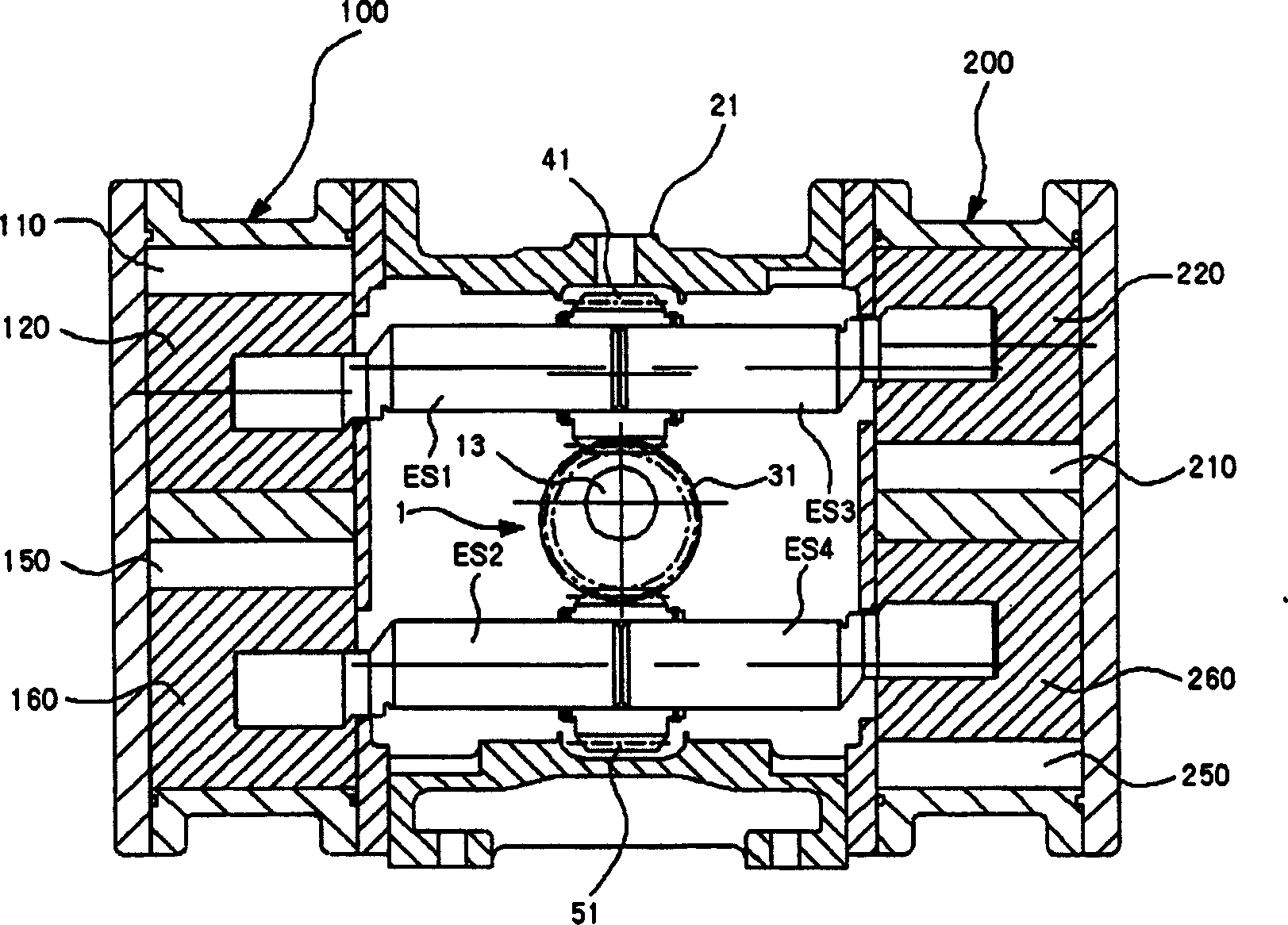

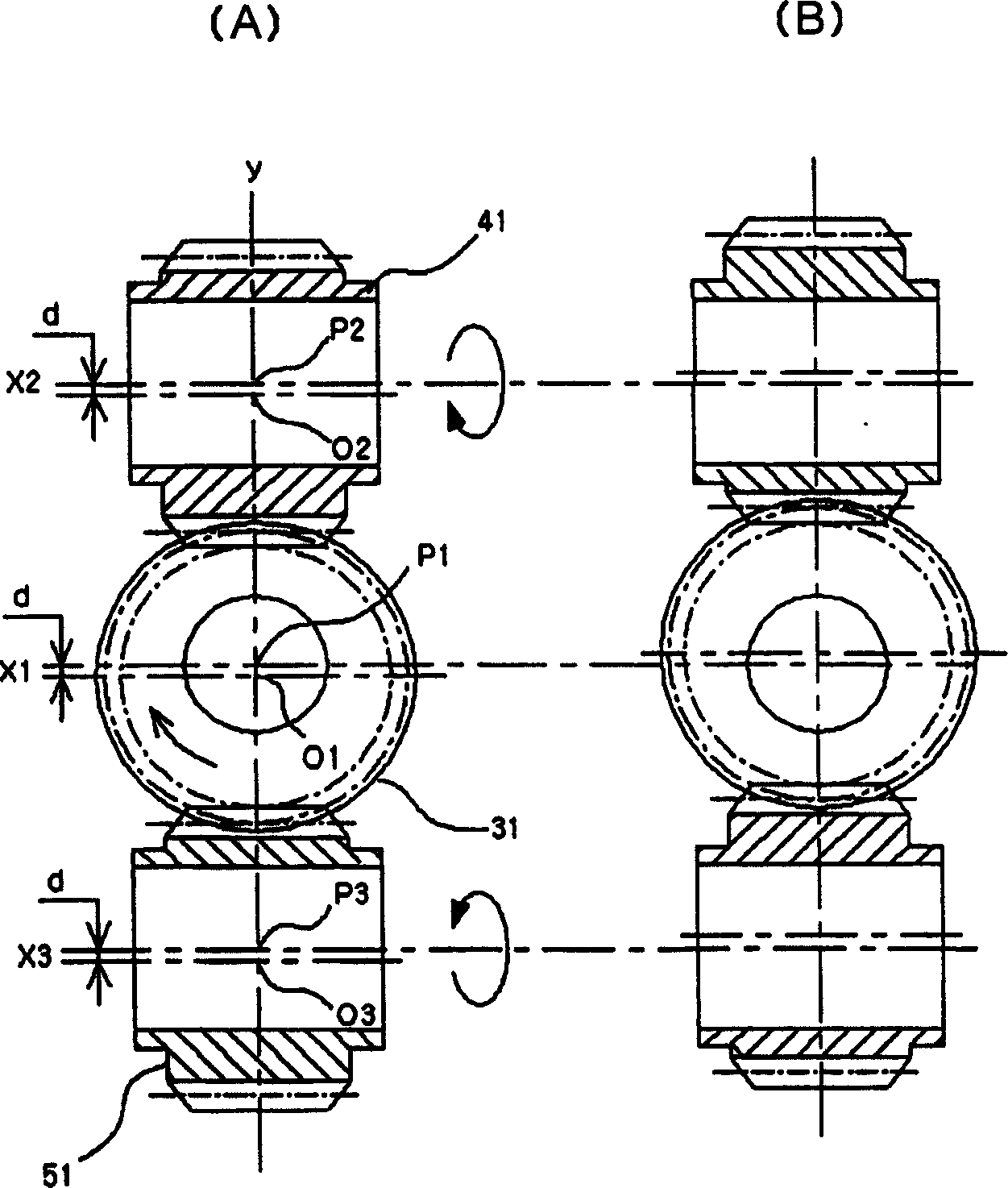

[0043] See figure 1 with figure 2 , The quadruple pump according to the first embodiment of the present invention includes: a gear box 21, which is arranged between the first cylinder block 100 and the second cylinder block 200; a transmission device 1 arranged in the gear box 21, which is connected to the motor 11 The drive shaft 13 is connected; the four eccentric shafts ES1 to ES4 are respectively mounted on the transmission device 1; and the four pistons 120, 160, 220, 260 are respectively mounted on the eccentric shafts ES1 to ES4, which are located in the first cylinder The upper and lower volume chambers 110, 150 of the body 100 and the upper and lower volume chambers 210, 250 of the second cylinder 200.

[0044] in figure 1 In this case, reference numeral 500 denotes a suction pipe connected to the suction ports of the first cylinder 100 and the second cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com