Method and system for mechanical granulation of metallurgy slag and waste heat recovery

A waste heat recovery system and waste heat recovery technology, applied in the field of metallurgy, can solve the problems of no steel slag waste heat recovery system, no energy saving and environmental protection, low granulation efficiency, etc., and achieve the effects of saving manpower, energy and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

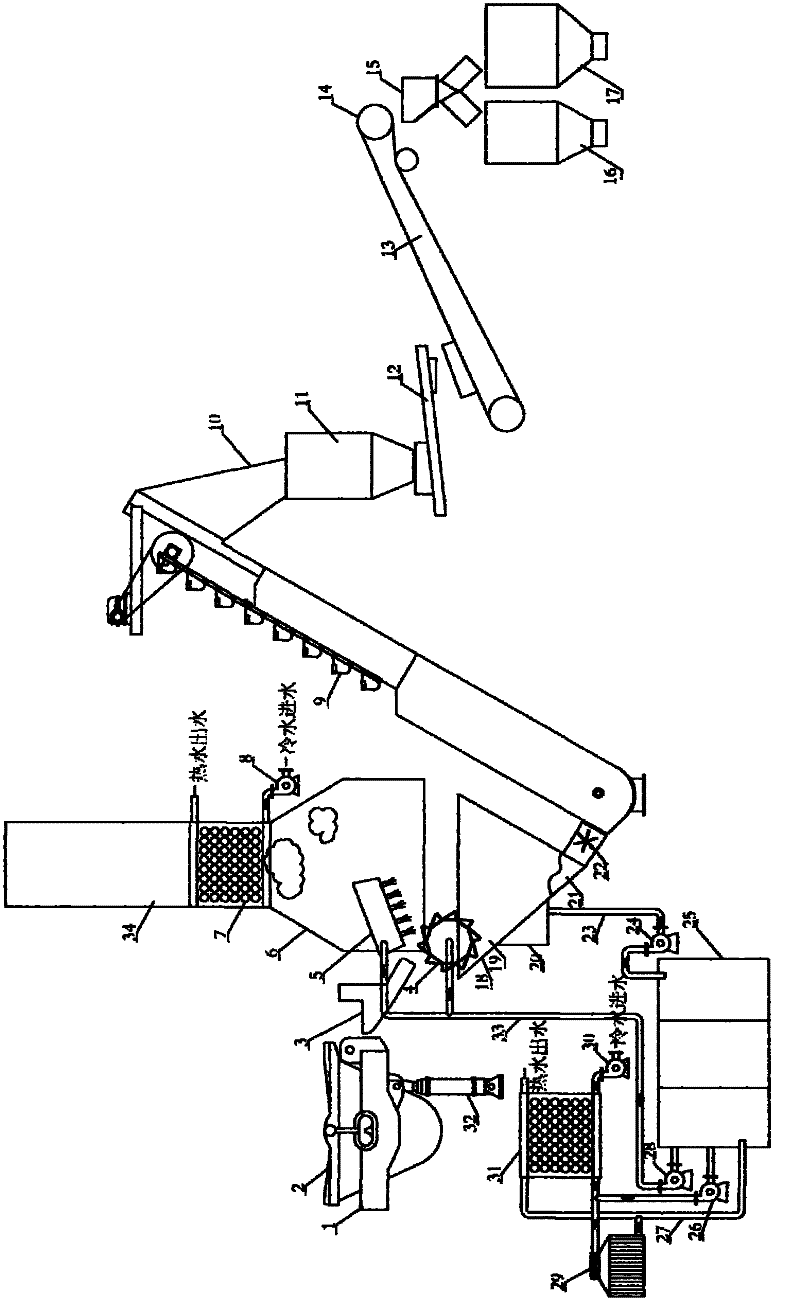

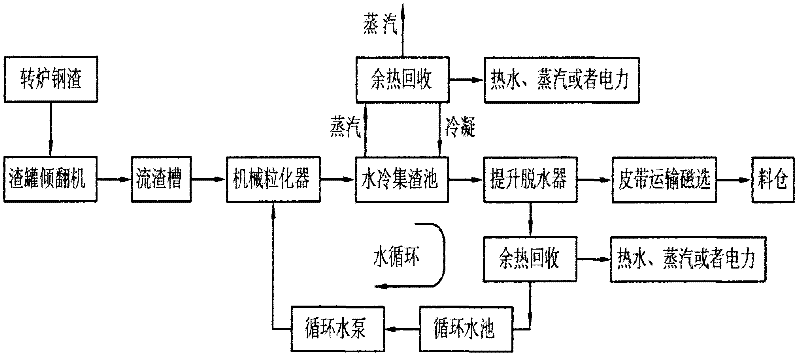

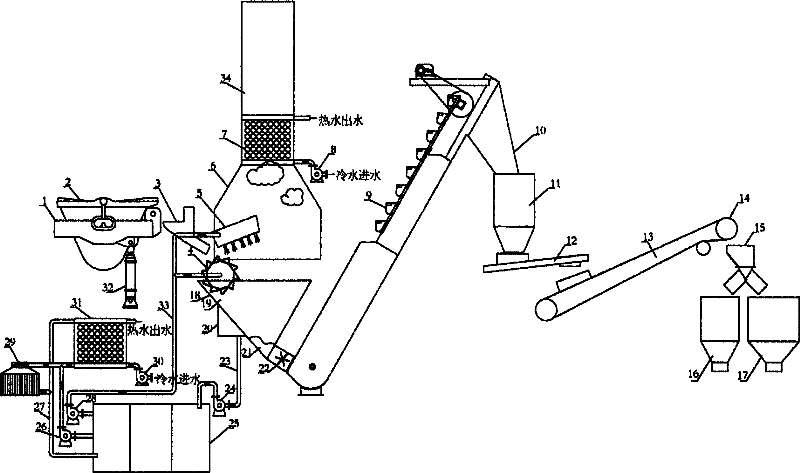

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0043] The main idea of the technical solution of the present invention is that the metallurgical slag enters the slag flowing slag trough into the mechanical granulation device with serial flow water cooling, and the slag is mechanically granulated while being sprayed and cooled by the spray water cooling device in the water-cooled mechanical granulation device. Then fall into the water-cooled slag collection tank, fully cool in the water-cooled slag collection tank to release heat, and then take the granulated and cooled granulated slag out of the water-cooled slag collection tank through the feeder and lifting dehydration device, and fully dehydrate during the lifting process , and then enter the intermediate storage bin through the discharge chute or store directly on the ground, realizing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com