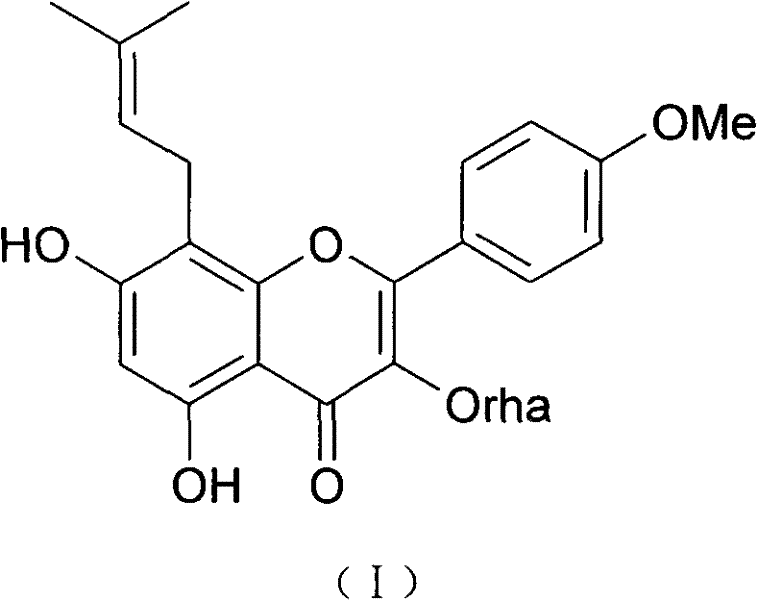

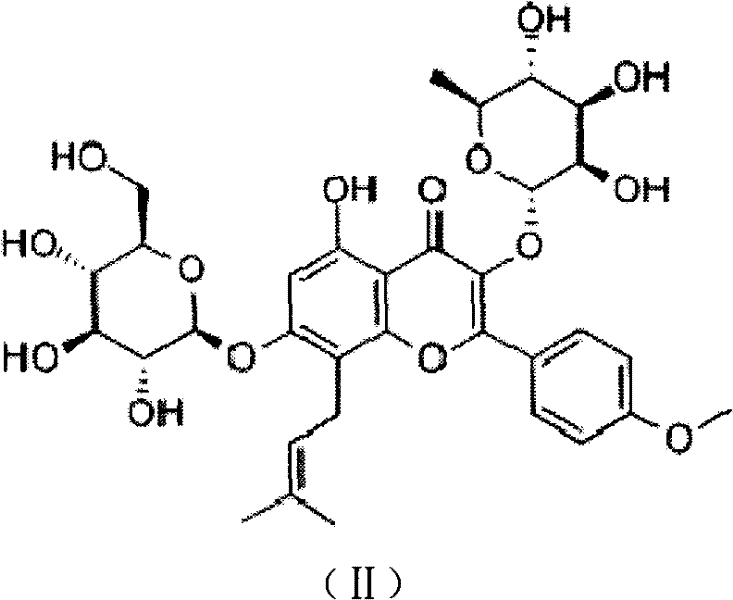

Preparation method of baohuoside I

A technology of baohuoside and icariin, which is applied in the field of preparation of baohuoside I, can solve the problems of low conversion rate, complicated operation, difficult separation and purification, and achieve improved reaction efficiency, high enzymatic hydrolysis reaction efficiency, and dissolution fast speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 2 g of icariin (purity 95.7%) and dissolve it in 500 mL of 50% ethanol, and dissolve 0.5 g of β-glucosidase in 330 mL of water, slowly add the dilute ethanol solution of icariin into the enzyme aqueous solution, The concentration of ethanol was diluted to 30%, stirred at 37°C for 6 hours, the reaction solution was evaporated in vacuo to remove the solvent, and the conversion rate of icariin was detected by high performance liquid phase method. As a result, 98.5% of icariin was converted into Huoside I.

[0024] Take 2 g of icariin (purity 95.7%) and 0.5 g of β-glucosidase, disperse them in 830 mL of water, stir at 37 ° C for 6 hours, evaporate the reaction solution in vacuum, remove the solvent, and detect the epimedium by HPLC The conversion rate of glycosides showed that 36.3% of icariin was converted into baohuoside I.

[0025] Take 2 g of icariin (purity 95.7%) and 0.5 g of β-glucosidase, disperse them in 830 mL of 30% ethanol, stir at 37° C. for 6 hours, evap...

Embodiment 2

[0027] Dissolve 2 g of icariin (purity 95.7%) in 500 mL of 50% dilute ethanol, and dissolve 0.5 g of β-glucosidase in 330 mL of water, slowly add the dilute ethanol solution of icariin into the enzyme aqueous solution , dilute the ethanol concentration to 30%, and stir at 37° C. for 6 hours. After the reaction, add an equal amount of ethanol to precipitate β-glucosidase, filter the filtrate, and evaporate the solvent to obtain 1.52 g of Baohuoside I crude product. Repeated recrystallization with absolute ethanol 3 times to obtain 1.08 g of baohuoside I with a purity of 99.5%.

[0028] Take 2 g of icariin (purity 95.7%) and 0.5 g of β-glucosidase, disperse them in 830 mL of water, stir at 37°C for 6 hours, add an equal amount of ethanol to precipitate β-glucosidase after the reaction, and filter to get the filtrate , Evaporate the solvent to get 1.72g of the crude product of Dibaohuoside I. Repeated recrystallization with absolute ethanol 3 times to obtain 0.31 g of baohuoside...

Embodiment 3

[0033] Take 2 g of icariin (purity 65.7%) and dissolve it in 500 mL of 50% dilute ethanol, and dissolve 1 g of cellulase in 330 mL of water. Slowly add the dilute ethanol solution of icariin into the enzyme aqueous solution to make ethanol Dilute the concentration to 30%, and stir at 40°C for 12 hours. After the reaction, add an equal amount of ethanol to precipitate the cellulase, filter the filtrate, and evaporate the solvent to obtain 1.55 g of the crude product of Baohuoside I, which is absorbed by D101 macroporous resin , eluted with water, 30% ethanol, and 60% ethanol respectively, collected the 60% ethanol part, vacuum rotary evaporation, removed the solvent, repeated recrystallization 2 times from absolute ethanol, and obtained 0.55 g of baohuoside I with a purity of 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com