High temperature resistance polycarbonate composite material and preparation method thereof

A technology of polycarbonate and composite materials, applied in the field of polymer materials, can solve problems such as difficult popularization and application, complex polymerization process, difficult to meet the use requirements, etc., achieve low cost, meet design and use requirements, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

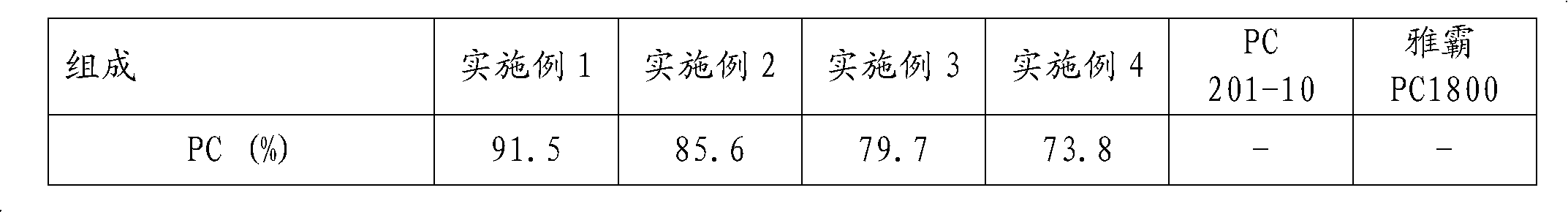

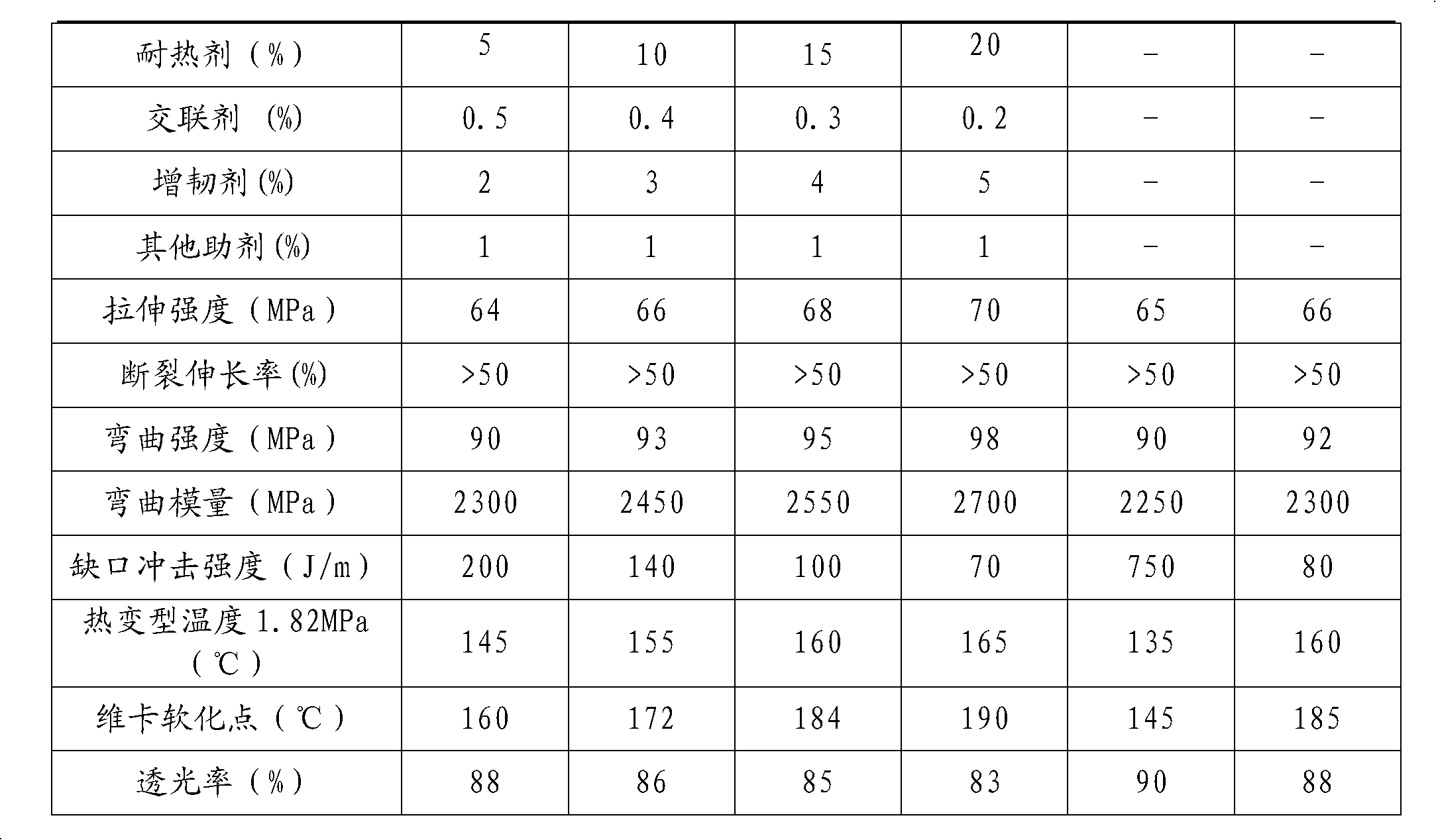

Embodiment 1

[0030] Example 1 Put 91.5% PC by weight, 5% heat-resistant agent, 0.5% crosslinking agent, 2% toughening agent, and 1% other additives into a mixing tank for 15 minutes of thorough mixing , Put the mixed material into the twin-screw extruder to melt and knead, extrude, and granulate. The screw diameter of the twin-screw extruder is 35mm, the ratio of screw length to diameter is set to 32, and the extrusion temperature The first zone temperature is 260°C, the second zone temperature is 270°C, the third zone temperature is 280°C, the fourth zone temperature is 270°C, the head temperature is 285°C, the residence time is 1.4min, and the pressure is 15MPa.

Embodiment 2

[0031] Example 2 Put 85.6% PC by weight, 10% heat-resistant agent, 0.4% crosslinking agent, 3% toughening agent, and 1% other additives into a mixing tank for 15 minutes of thorough mixing , Put the mixed material into the twin-screw extruder to melt and knead, extrude, and granulate. The screw diameter of the twin-screw extruder is 35mm, the ratio of screw length to diameter is set to 36, and the extrusion temperature The first zone temperature is 270°C, the second zone temperature is 280°C, the third zone temperature is 290°C, the fourth zone temperature is 280°C, the head temperature is 295°C, the residence time is 1.0min, and the pressure is 12MPa.

Embodiment 3

[0032] Example 3 Put 79.7% PC by weight, 15% heat-resistant agent, 0.3% crosslinking agent, 4% toughening agent, and 1% other additives into a mixing tank for 15 minutes of thorough mixing , Put the mixed material into the twin-screw extruder to melt and knead, extrude, and granulate. The screw diameter of the twin-screw extruder is 35mm, the ratio of screw length to diameter is set to 28, and the extrusion temperature The first zone temperature is 270°C, the second zone temperature is 285°C, the third zone temperature is 310°C, the fourth zone temperature is 300°C, the head temperature is 315°C, the residence time is 0.6min, and the pressure is 16MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com