Method for producing long-acting drip agent for agricultural polyethylene film

A polyethylene film and production method technology, applied in the field of dripping agents, can solve the problems of seed and vegetable fruit mildew damage, short duration, rotten cabbage core and root, etc., and achieve appropriate migration rate, high transparency, long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

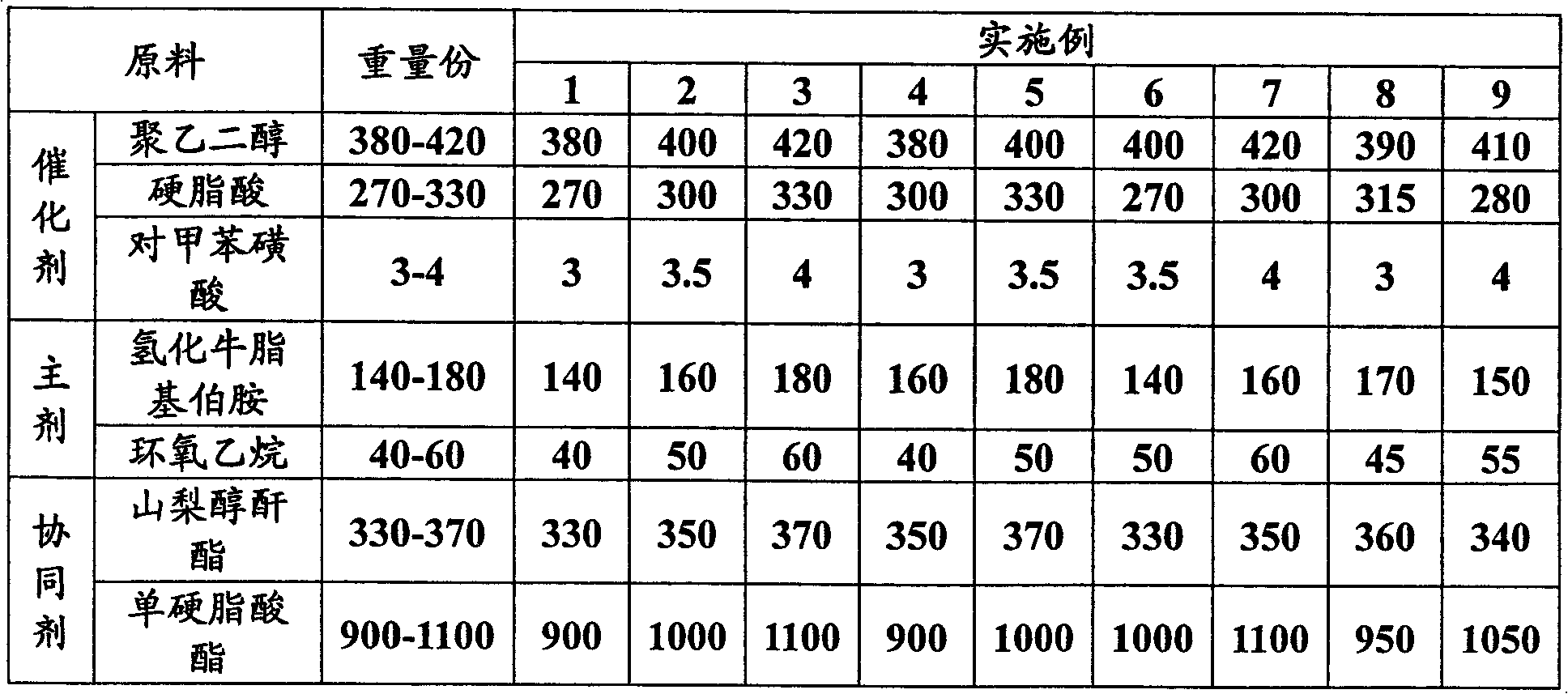

Embodiment 1

[0014] Embodiment 1 (see Table 1 corresponding to the raw materials of Embodiment 1 and the proportioning value thereof by weight): 380 parts of polyethylene glycol, 270 parts of stearic acid, and 3 parts of p-toluenesulfonic acid are added to the reactor, all valves are closed, Raise the temperature, stir after the mixture is completely melted, evacuate to negative 0.1Mpa, heat up to 150°C, stir for 4 hours, measure the acid value to 2-4, terminate the reaction, cool and discharge the material to prepare the catalyst; first, 140 parts of paste Add the hydrogenated tallow primary amine to the reaction kettle after heating and melting, then heat up to 120°C, vacuumize (-0.1Mpa) and fill with nitrogen, raise the temperature to 145°C in a nitrogen atmosphere, and then start adding slowly in 20-30min 40 parts of ethylene oxide, fully stirred, the reaction is carried out at 168-175°C and 2.5kg pressure, after all the ethylene oxide is added, the heat preservation is delayed for 10 m...

Embodiment 11

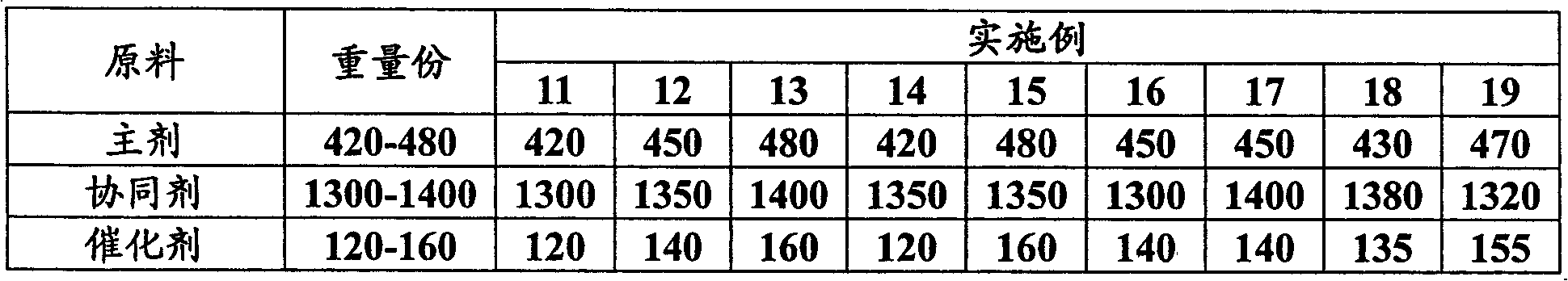

[0018] Example 11 (refer to Table 2 for the corresponding examples of raw materials and their weight ratios): Add 420 parts of main agent, 1300 parts of synergist and 120 parts of catalyst into the reactor, heat up to 105°C while stirring, stir for 1 hour and pump Vacuum-dry until it is suitable for slicing or granulating, cool down and discharge, after slicing or slicing, inspect and pack.

[0019] For the rest of Examples 12-19, refer to Table 2 for the corresponding examples of raw materials and their proportions by weight, and use the same method as Example 11 to prepare the long-acting dripping agent, and Examples 11-13 are preferred.

[0020] In order to reduce the cost, the method adopts industrial-grade chemical raw materials for the raw materials that do not affect the transparency of the film, and uses analytically pure raw materials for the raw materials that affect the transparency. While using lipophilic long carbon chain N,N-bis(2-hydroxyethyl)alkylamine as the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saponification value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com