Dynamic slight press fan-shaped section hydraulic system leakage fault on-line judging and early warning method

A technology of hydraulic system and sector segment, applied in the field of continuous casting equipment maintenance in the metallurgical industry, can solve the problems of low judgment accuracy, harsh working environment, high labor intensity, etc., so as to improve product quality, improve process control level, and increase economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

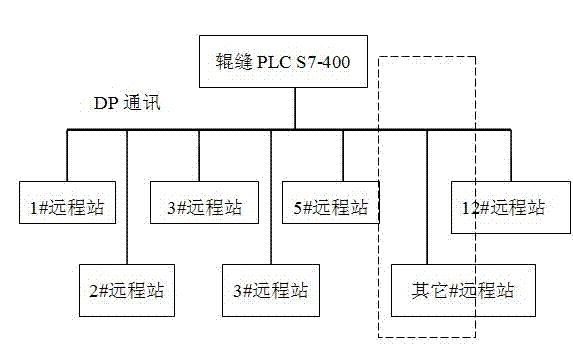

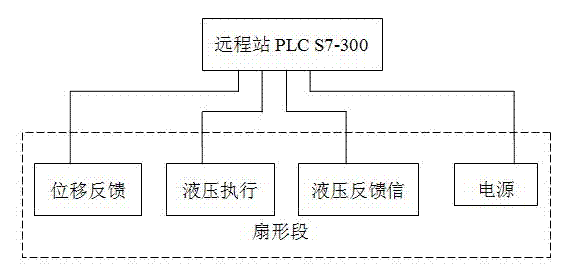

Method used

Image

Examples

Embodiment 1

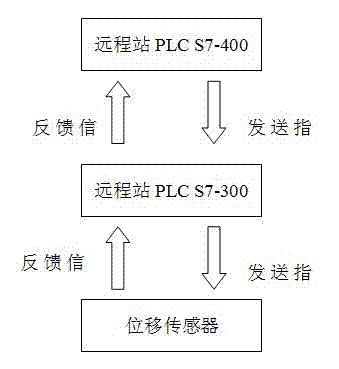

[0027] Example 1: The locking device of the hydraulic system of the sector section is faulty.

[0028]When the constant pulling speed, constant water volume, and displacement sensor feedback value are stable within 10 cycles, the "PLC S7-400" sends an instruction to "PLC S7-300" to lock the hydraulic system of the sector, and the hydraulic system of the 6# sector is At this time, the hydraulic oil in the upper and lower chambers of A hydraulic cylinder, B hydraulic cylinder, C hydraulic cylinder, and D hydraulic cylinder on the sector remains closed, and the hydraulic oil in the upper and lower chambers of the "PLC S7-300" will be transferred from "PLC S7-300" to "PLC S7- 400” feeds back the change of oil pressure in this sector, taking the data in hydraulic cylinder A as an example, the following table shows:

[0029]

[0030] The process of judging the relationship between P0 and P1 is as follows: when the pressure difference between P1 and P0 is 4.7 MPa and is greater ...

Embodiment 2

[0031] Embodiment 2: The seal at the piston in the sector hydraulic cylinder fails.

[0032] When the constant pulling speed, constant water volume, and displacement sensor feedback value are stable within 10 cycles, the "PLC S7-400" sends an instruction to "PLC S7-300" to lock the hydraulic system of the sector, and the hydraulic system of the 7# sector is At this time, the hydraulic oil in the upper and lower chambers of A hydraulic cylinder, B hydraulic cylinder, C hydraulic cylinder, and D hydraulic cylinder on the sector remains closed, and the hydraulic oil in the upper and lower chambers of the "PLC S7-300" will be transferred from "PLC S7-300" to "PLC S7- 400” feeds back the change of oil pressure in this sector, taking the data in hydraulic cylinder A as an example, the following table shows:

[0033]

[0034] The process of judging the relationship between P0 and P1 is as follows: when the pressure difference between P1 and P0 is 4.72 MPa, which is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com