Manufacturing method of X65 pipeline steel longitudinal submerged arc welded pipe for undersea use

A technology of straight seam submerged arc and manufacturing method, applied in manufacturing tools, arc welding equipment, welding equipment, etc., can solve problems such as destructive damage and leakage of production environment in sea areas, and achieve the effect of ensuring performance, uniform performance and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

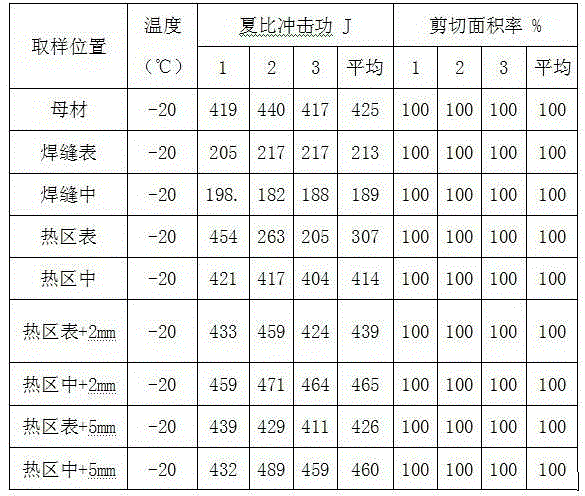

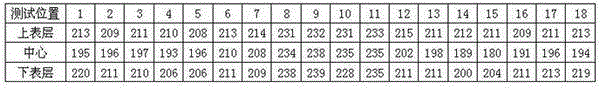

Embodiment 1

[0033] The wall thickness is 28.6mm, the chemical composition is C 0.06%, Mn 1.61%, Si 0.19%, S 0.0012%, P 0.007%, Mo ≤0.098%, Ni+Cr+Cu 0.157%, V+Nb+Ti 0.062% , N 0.005%, Ceq 0.36, Pcm 0.15 X65 controlled rolling steel plate for the manufacture of straight seam submerged arc welded pipe, the manufacturing process is as follows:

[0034] Edge milling: After edge milling, the steel plate conforms to the upper and lower groove angles of 35°, and the height of the blunt edge is 9mm.

[0035] Pre-bending: use the pre-bending machine to pre-bend the edge of the plate, and make the edge of the plate have a curvature that meets the requirements according to the requirements of the pipe diameter.

[0036]JCO Forming: Using the method of step-by-step pressing, the steel plate is fed 134mm each time. First, half of the steel plate is pressed into a "J" shape by 7 times, and the other half is pressed in the same way to form a "C" shape. Pressing is carried out in the middle, so that the ...

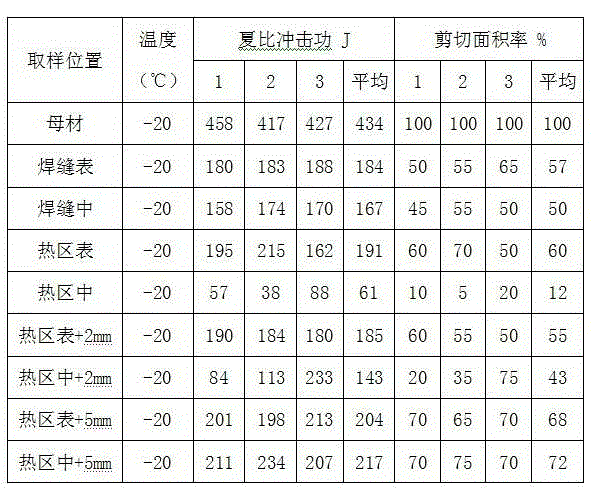

Embodiment 2

[0061] The wall thickness is 30.2mm, the chemical composition is C 0.07%, Mn 1.58%, Si 0.31%, S 0.001%, P 0.007%, Mo ≤0.014%, Ni+Cr+Cu 0.216%, V+Nb+Ti 0.046% , N 0.004%, Ceq 0.40, Pcm 0.18 X65 controlled rolling steel plate for the manufacture of straight seam submerged arc welded pipe, the manufacturing process is as follows:

[0062] Edge milling: After edge milling, the steel plate conforms to the upper and lower groove angles of 35°, and the height of the blunt edge is 9.0mm.

[0063] Pre-bending: use the pre-bending machine to pre-bend the edge of the plate, and make the edge of the plate have a curvature that meets the requirements according to the requirements of the pipe diameter.

[0064] JCO Forming: Using the method of step-by-step pressing, the steel plate is fed 134mm each time. First, half of the steel plate is pressed into a "J" shape by 7 times, and the other half is pressed in the same way to form a "C" shape. Pressing is carried out in the middle, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com