Method for rapidly preparing glycopeptides

A glycopeptide, rapid technology, applied in the field of polypeptide glycosylation grafting, to achieve the effect of overcoming uneven reaction, strong industrial operability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

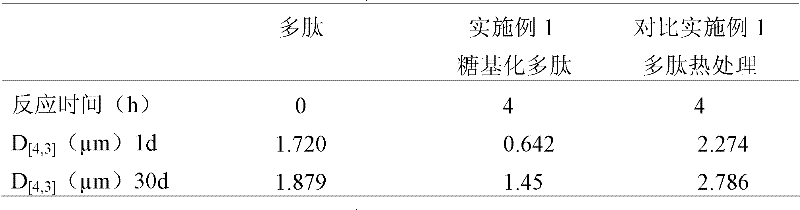

[0027] Prepare soybean protein into a solution with a mass fraction of 10%, heat it to 37°C, add pepsin (enzyme: protein amount = 1:100), enzymolyze it for 30 minutes, heat it to 100°C for 3 minutes to inactivate the enzyme, centrifuge (5000rpm, 20min), take the supernatant and freeze-dry it, which is soybean polypeptide. Put 1.0g dextran as a crowding reagent in a closed container, add 10mL 0.01mol / L sodium phosphate buffer solution with pH 6.5, stir for 2h to fully dissolve it, add 0.5g soybean polypeptide and 1.0g dextran to the In the solution containing the crowding reagent, after fully stirring for 2 hours, add 2 drops of NaN 3 (0.02% w / w) anti-corrosion, after standing at 5°C overnight, stirring at 60°C for 4h, cooling to 25°C to terminate the reaction after the reaction, centrifuging (8000rpm, 20min), and freeze-drying the supernatant to obtain glycopeptide products.

[0028] The above-mentioned glycopeptide products were used to prepare emulsions, and after standing ...

Embodiment 2

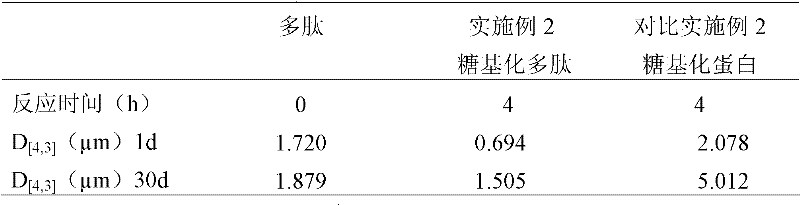

[0036]Prepare soybean protein into a solution with a mass fraction of 10%, heat it to 37°C, add pepsin (enzyme: protein amount = 1:100), enzymolyze it for 30min, then heat it to 100°C for 3min to inactivate the enzyme, centrifuge (5000rpm, 20min), take the supernatant and freeze-dry it, which is soybean polypeptide. Put 2.0g dextran in the reaction device as a crowding reagent, add 10mL 0.01mol / L sodium phosphate buffer solution with pH 5.5, stir for 2h to fully dissolve it, add 0.25g soybean polypeptide and 0.25g dextran to the reaction device In the solution containing the crowding reagent, after fully stirring for 2 hours, add 2 drops of NaN 3 (0.02% w / w) anti-corrosion, after standing overnight at 5°C, stir at a constant temperature of 70°C for 4 hours, after the end of the reaction, quickly cool to 25°C to terminate the reaction, centrifuge (8000rpm, 20min), and freeze-dry the supernatant to obtain the glycopeptide product .

[0037] The above-mentioned glycopeptide pro...

Embodiment 3

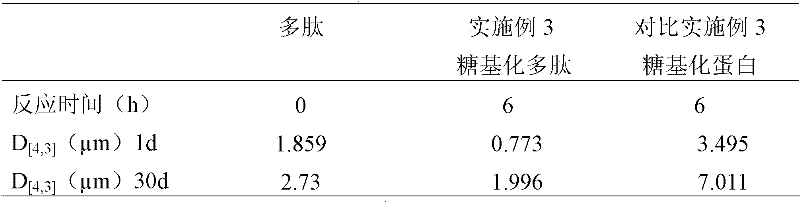

[0045] Prepare defatted soybean powder into a solution with a mass fraction of 10%, heat it to 55°C, add neutral protease (enzyme: protein amount = 1:100), enzymolyze it for 30min, then heat it to 100°C for 3min to inactivate the enzyme, centrifuge ( 5000rpm, 20min), take the supernatant and freeze-dry it, which is soybean polypeptide. Put 1.0g of polyethylene glycol 2000 as a crowding reagent in the reaction device, add 10mL of 0.01mol / L sodium phosphate buffer solution with pH 7.0, stir for 2 hours to fully dissolve it, and mix 1.0g of soybean polypeptide and 0.5g of dextran Add to the solution containing the crowding reagent, stir well for 2h, add 2 drops of NaN 3 (0.02% w / w) anti-corrosion, after standing at 5°C overnight, stir at constant temperature 50°C for 6h, after the reaction is completed, quickly cool to 25°C to terminate the reaction, centrifuge (8000rpm, 20min), and freeze-dry the supernatant to obtain the glycopeptide product .

[0046] The above-mentioned gly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com