Motor-driven four-way reversing valve

A four-way reversing valve, motor-driven technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problem of inability to reverse the rotor action timing, time and rotation angle control, four-way valve does not have cost advantages, Problems such as the structure of the four-way valve are not disclosed, so as to achieve the effect of easy product quality assurance, saving of motor cost and control circuit cost, and high operation reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

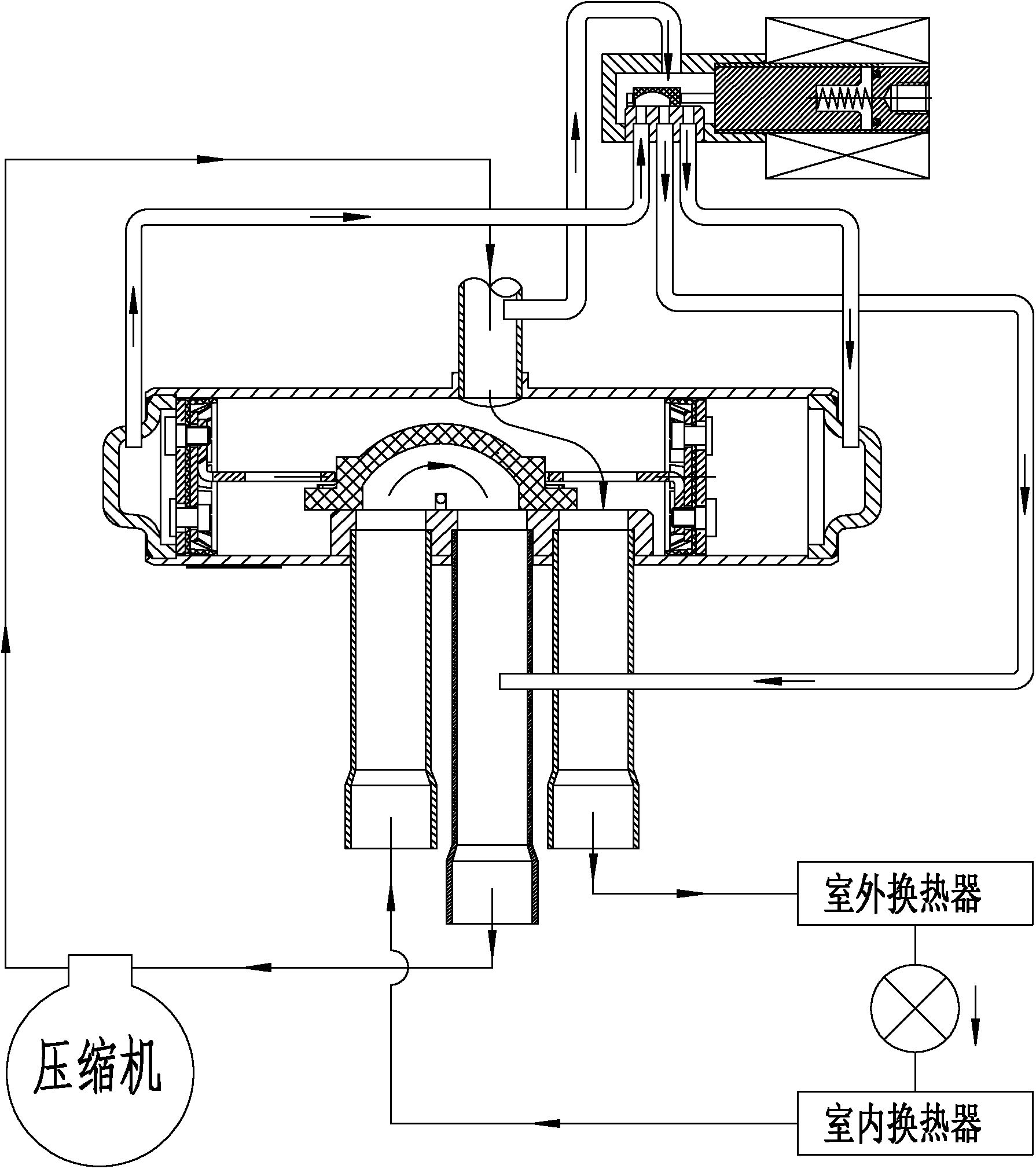

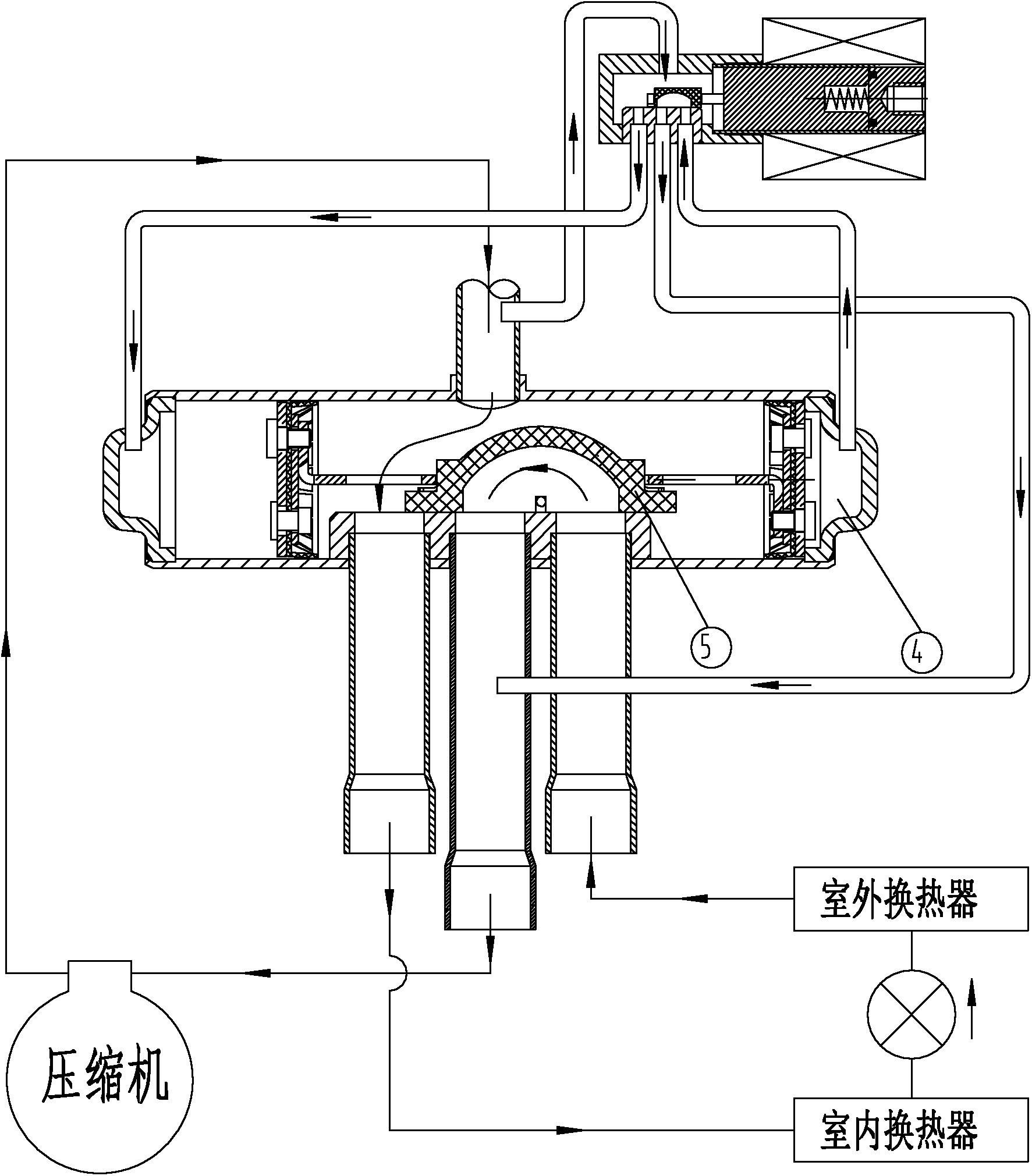

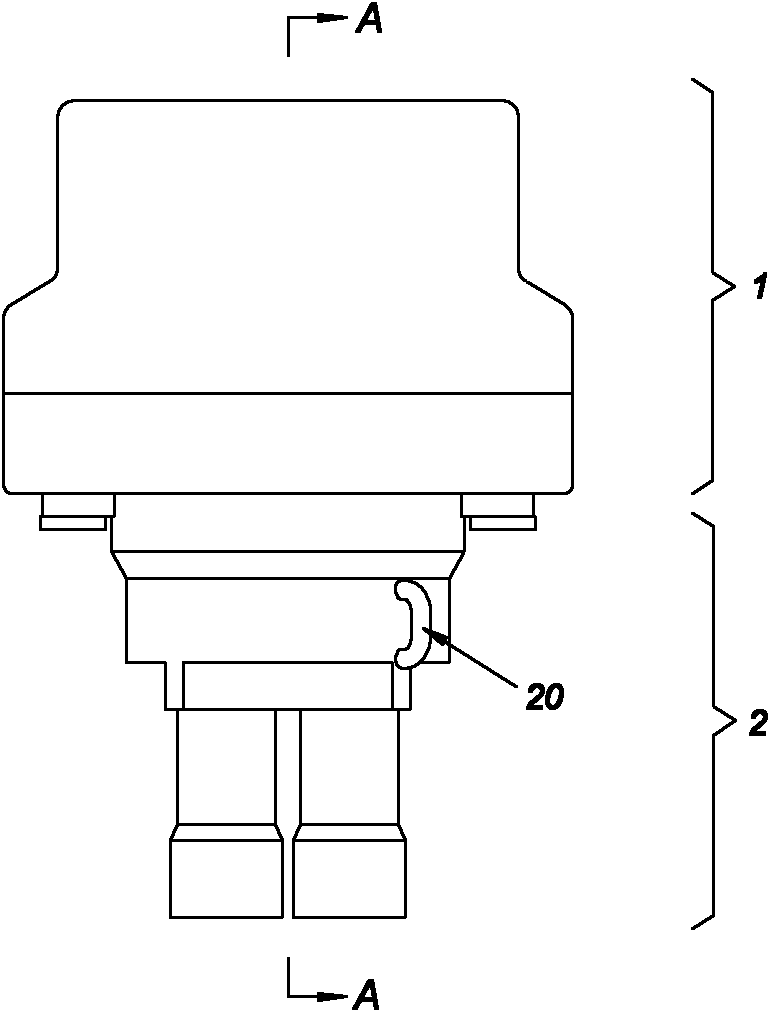

[0061] Such as image 3 , Figure 4 As shown, the motor-driven four-way reversing valve of this embodiment includes a driving device 1 and a four-way reversing valve body 2 connected together. in:

[0062] a) The driving device 1 includes: a box cover 3, a box seat 4, a synchronous motor 5, a cam member 6, a first microswitch 7 as the first in-position switch, a second microswitch 8 as the second in-position switch, and a circuit board 9 , heating power supply line 10 , cooling power supply line 11 and common line 12 .

[0063] The box cover 3 and the box seat 4 are connected together by screws to form a box body; the synchronous motor 5, the cam member 6, the first microswitch 7, the second microswitch 8, and the circuit board 9 are all in the box body; the cam member 6 is coaxially installed on the output shaft 13 of the synchronous motor 5, and serves as a coupling between the output shaft 13 and the following input shaft 18; the first microswitch 7 and the second micros...

Embodiment 2

[0071] Such as Figure 17 , Figure 18 As shown, the difference between this embodiment and Embodiment 1 is that the other end of the input shaft 18' is directly inserted into the slot on the reversing rotor 16', and the two do not transmit through metal sheets. In addition, a sealing ring 19' is provided between the valve body gland 15' and the valve body casing 14'.

Embodiment 3

[0073] Such as Figure 19 , Figure 20 As shown, the difference between this embodiment and Embodiment 1 lies in: the shape of the reversing rotor 16 ″ and the first nozzle 21 ″, the second nozzle 22 ″, and the third nozzle 23 ″ on the valve housing 14 ″ It is different from the drawing direction of the fourth nozzle 24 ". Specifically, the reversing rotor 16 "is integrated with the input shaft 18", and a partition 26 "is formed on the reversing rotor 16 ", and the partition 26 "is arranged along the diameter direction of the reversing rotor 16 ", and is perpendicular to The end face of the reversing rotor 16", the two sides of the partition plate 26" correspond to the two refrigerant passages of the reversing rotor 16"; the first nozzle 21", the second nozzle 22", the third nozzle 23" and the second nozzle Four nozzles 24 " are drawn from the direction perpendicular to the input shaft 18 " of the reversing rotor 16 " on the valve housing 14 ". Such as Figure 20 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com