Technology and equipment for separating coal and gangue and refilling gangue

A technology of gangue and equipment, applied in the field of technical equipment, can solve the problems of increasing goaf space, aggravating surface subsidence, wasting manpower and material resources, etc., and achieves the effects of saving costs, facilitating equipment maintenance, and facilitating traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following related technical contents are the technology of the present invention.

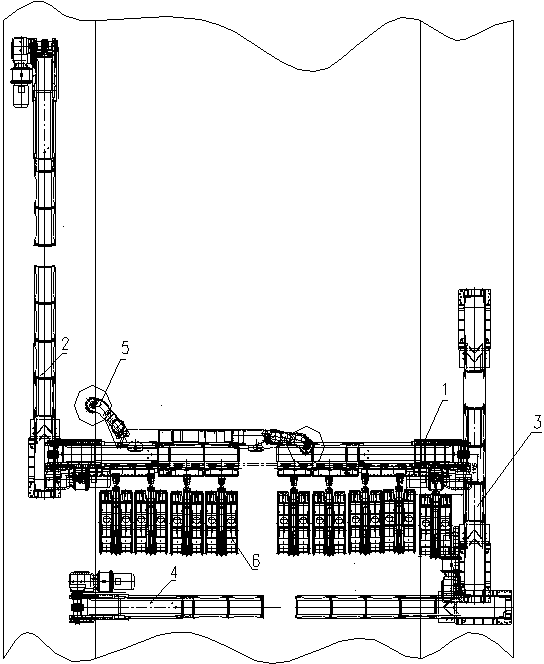

[0029] A complete set of equipment for separating and backfilling coal and gangue, such as figure 1 Shown: including a shearer 5, below the shearer 5 there is a working front scraper conveyor 1 that can rotate forward and reverse, the working front scraper conveyor 1 cooperates with the shearer 5 and carries Shearer cutting.

[0030] The forward rotating conveying end of the scraper conveyor 1 at the front of the working front is matched with a coal loader 2 along the trough.

[0031] The reverse transport end of the scraper conveyor 1 at the front of the working face is matched with a gangue recirculation carrier 3; Back of bracket.

[0032] A gangue-throwing scraper conveyor 4 is provided in cooperation with the gangue rotary carrier 3; the gangue-throwing scraper conveyor 4 is suspended at the rear of the hydraulic support 6 and the size of the opening of the middle plate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com