Ethylene propylene diene monomer rubber material for automobile cooling system sealing elements and preparation method thereof

A technology for EPDM rubber and automobile cooling, which is applied in the field of peroxide vulcanized rubber materials and its preparation, can solve the problems of low compression set performance, achieve high strength performance, resistance to superheated cooling liquid immersion, excellent low Effect of Compression Set Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

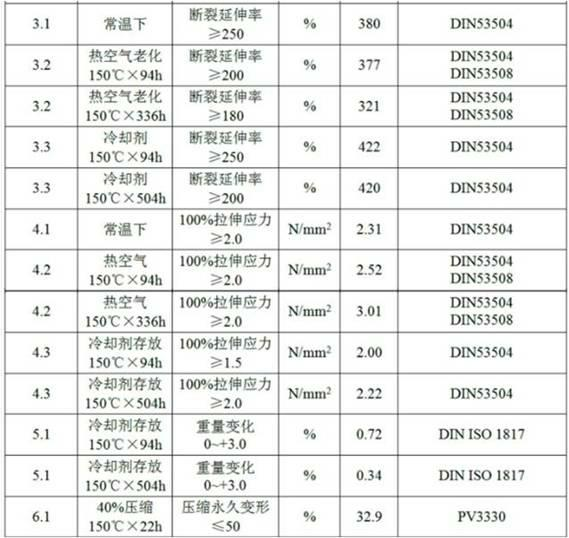

Examples

Embodiment 1

[0024] The EPDM rubber material used for the automobile cooling system seal in this embodiment, its components and percentages are shown in Table 1.

[0025] Table 1 Components and percentages of EPDM material in Example 1

[0026] Raw material name Percentage % EPDM rubber 58 High wear-resistant carbon black 24 semi-reinforcing carbon black 8 Zinc oxide 3 stearic acid 0.7 4,4'bis(phenylisopropyl)diphenylamine 1.5 2-Mercaptomethylbenzimidazole Zinc Salt 0.7 α,α'-Di-tert-butylperoxydicumylbenzene 2.3 triallyl isocyanurate 1.8

[0027] In the above table, EPDM raw rubber is 580HT EPDM rubber produced by American Lion Chemical Company; high wear-resistant carbon black is N330 high wear-resistant carbon black produced by Cabot Company; semi-reinforcing carbon black is N774 semi-reinforcing carbon black produced by Suzhou Baohua Carbon Black Co., Ltd.; zinc oxide is an indirect zinc oxide produced by Zhenjiang Ba...

Embodiment 2

[0040] The EPDM rubber material used for the automobile cooling system seal in this embodiment, its components and percentages are shown in Table 2.

[0041] Table 2 Components and percentages of EPDM materials in Example 2

[0042] Raw material name Percentage % EPDM rubber 53 High wear-resistant carbon black 25 semi-reinforcing carbon black 10 Zinc oxide 5 stearic acid 1 4,4'bis(phenylisopropyl)diphenylamine 1.5 2-Mercaptomethylbenzimidazole Zinc Salt 1 α,α'-Di-tert-butylperoxydicumylbenzene 2 triallyl isocyanurate 1.5

[0043] The source of each component in the above-mentioned table is with embodiment 1, adopts this component and percentage content thereof, and its preparation method is as follows:

[0044] (1) Masterbatch mixing:

[0045] Put the EPDM raw rubber in the internal mixer for 60 seconds to masticate the raw rubber and the powder compounding agent to ensure the product performance, and then ...

Embodiment 3

[0052] The EPDM material used for the automobile cooling system seal in this embodiment, its components and percentages are shown in Table 3.

[0053] Table 3 Components and percentages of EPDM material in Example 3

[0054] Raw material name Percentage % EPDM rubber 56 High wear-resistant carbon black 23.5 semi-reinforcing carbon black 9 Zinc oxide 5 stearic acid 0.5 4,4'bis(phenylisopropyl)diphenylamine 1 2-Mercaptomethylbenzimidazole Zinc Salt 0.5 α,α'-Di-tert-butylperoxydicumylbenzene 2.5 triallyl isocyanurate 2

[0055] The source of each component in the above-mentioned table is with embodiment 1, adopts this component and percentage content thereof, and its preparation method is as follows:

[0056] (1) Master batch mixing:

[0057] Put the EPDM raw rubber in the internal mixer for 80 seconds to masticate the raw rubber and the powder compounding agent to ensure the product performance, and then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness change | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com