High-temperature feeding and deslagging cracker for waste rubber and waste plastic

A pyrolysis device and technology for waste plastics, applied in the field of waste rubber and waste plastics high-temperature feed slag pyrolysis device, can solve the problems of energy consumption, increase of labor intensity, environmental pollution, etc., to achieve the elimination of power consumption, labor saving, pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

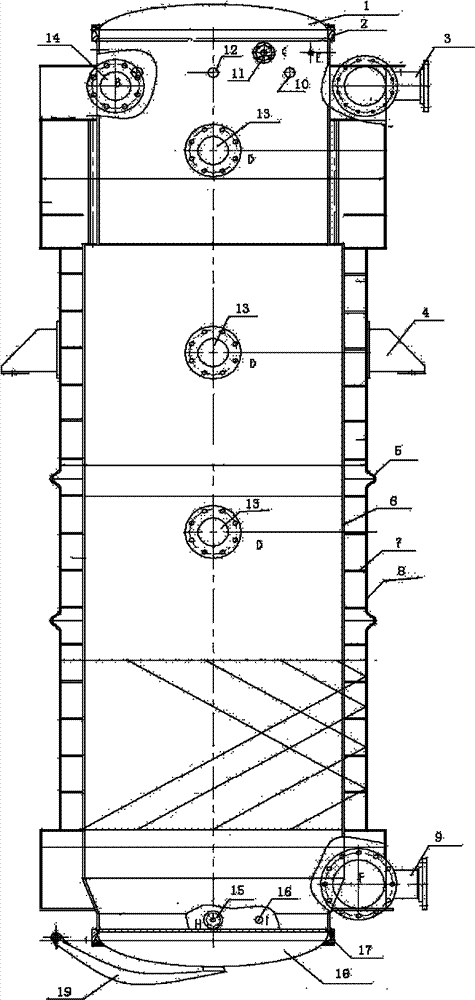

[0034] Such as figure 1 Shown is a waste rubber and waste plastics high-temperature feeding and slagging cracking device, the device includes a vertical kettle body, the upper port of the kettle body is the feed port, and the lower port of the kettle body is the discharge port , the upper port and the lower port are respectively provided with an upper cover 1 and a lower cover 17, and the upper cover 1 and the lower cover 17 are respectively connected to the kettle body through respective locking devices, and the kettle body The surrounding wall is provided with an oil and gas outlet 13, an exhaust port 3 and an air inlet 9, wherein the kettle body includes a concentric inner cylinder 6 and an outer cylinder 8, and the inner cylinder 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com