Method for modifying surface of precious metal by using stimuli-responsive polyether amine brush

A stimuli-responsive, polyetheramine technology, applied in the polymer field, can solve the problems of difficult to obtain functional polymer brushes, high requirements for experimental conditions, difficult to apply on a large scale, etc. Promising, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Synthesis of gPEA-SH

[0019] 1.28g (2mmol) PPO, 1.0g (1mmol) Jeffamine L100 and 0.077g (1mmol) mercaptoethylamine were added to 10mL of absolute ethanol, and the solution was reacted at 80°C for 24h under the protection of nitrogen. After cooling to room temperature, the solution was Pour into 10 times the volume of anhydrous ether, filter, and vacuum dry to obtain 2.2 g (93%) of gPEA-SH.

[0020] 2. Gold surface preparation

[0021] Silicon wafers were boiled in a mixed solution of concentrated sulfuric acid and hydrogen peroxide for 1 hour to obtain a clean surface. Spray gold on the surface of a clean silicon wafer to obtain a gold surface for experiments.

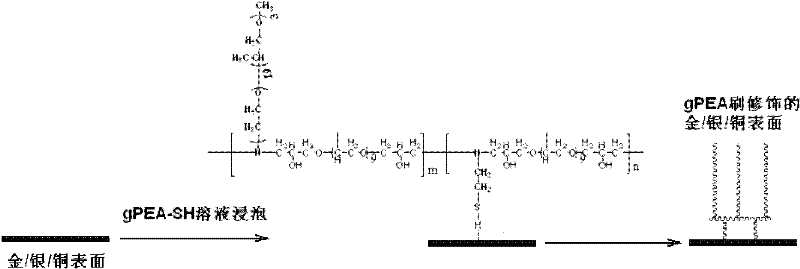

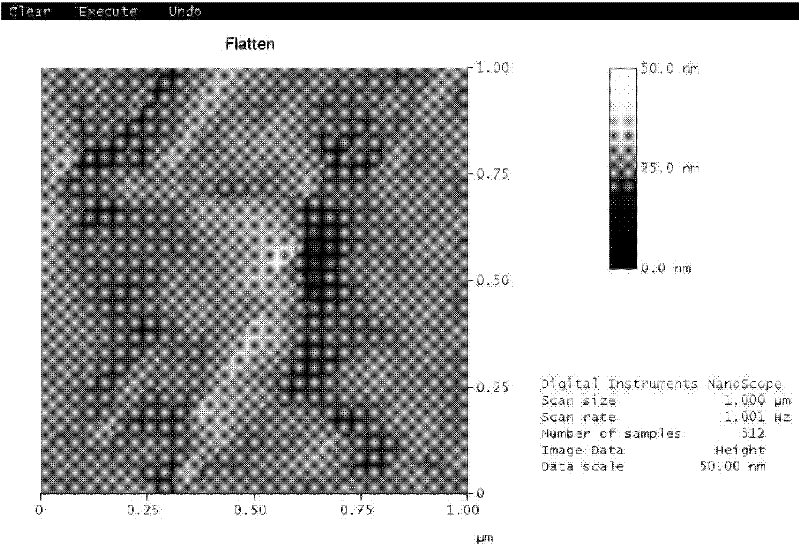

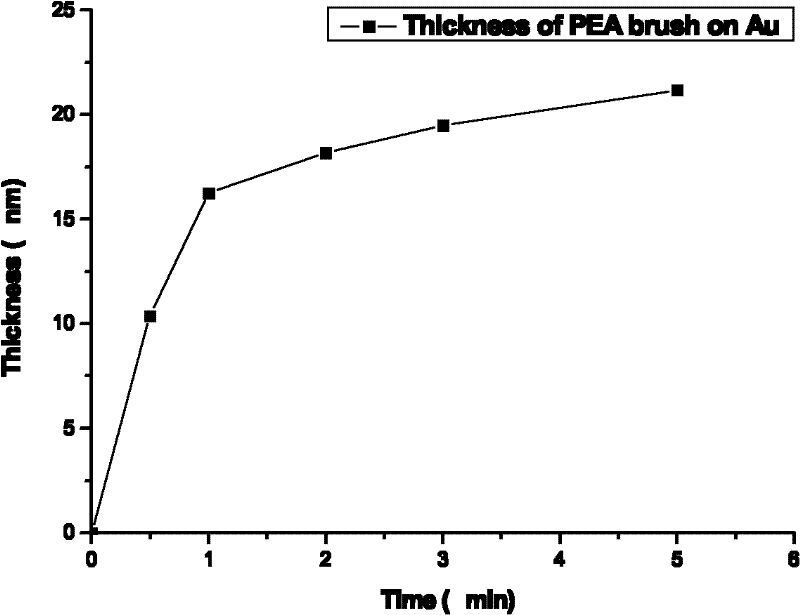

[0022] 3. Preparation of stimuli-responsive polyetheramine polymer brushes

[0023] Immerse the gold surface in a chloroform solution of gPEA-SH with a concentration of 100 mg / mL for 5 min. Take it out, sonicate in chloroform or ethanol for 1 min, wash the gPEA-SH adhered between the surfaces, and obtain ...

Embodiment 2

[0031] 1. Synthesis of gPEA-SH

[0032] Add 1.28g (2mmol) of PPO, 1.0g (1mmol) of Jeffamine L100 and 0.077g (1mmol) of mercaptoethylamine into 10mL of absolute ethanol, and react the solution at 80°C for 24h under the protection of nitrogen. After cooling to room temperature, the solution Pour into 10 times the volume of anhydrous ether, filter, and vacuum dry to obtain 2.2 g (93%) of gPEA-SH.

[0033] 2. Silver surface preparation

[0034] Silicon wafers were boiled in a mixed solution of concentrated sulfuric acid and hydrogen peroxide for 1 hour to obtain a clean surface. Spray silver on the surface of a clean silicon wafer to obtain a silver surface for experiments.

[0035] 3. Preparation of stimuli-responsive polyetheramine polymer brushes

[0036] Immerse the copper sheet in the chloroform solution of gPEA-SH with a concentration of 100mg / mL for 5h. Take it out, and sonicate in chloroform or ethanol for 1 min to clean the gPEA-SH adhered between the surfaces, and ob...

Embodiment 3

[0038] 1. Synthesis of gPEA-SH

[0039]1.28g (2mmol) PPO, 1.0g (1mmol) Jeffamine L100 and 0.077g (1mmol) mercaptoethylamine were added to 10mL of absolute ethanol, and the solution was reacted at 80°C for 24h under the protection of nitrogen. After cooling to room temperature, the solution was Pour into 10 times the volume of anhydrous ether, filter, and vacuum dry to obtain 2.2 g (93%) of gPEA-SH.

[0040] 2. Copper sheet surface treatment

[0041] The copper sheet was washed with dilute acid to remove the oxidizing agent, then washed with deionized water and dried.

[0042] 3. Preparation of stimuli-responsive polyetheramine polymer brushes

[0043] Immerse the copper sheet in the chloroform solution of gPEA-SH with a concentration of 100mg / mL for 5h. Take it out, and sonicate in chloroform or ethanol for 1 min to clean the gPEA-SH adhered between the surfaces, and obtain a copper surface modified with a stimuli-responsive polyetheramine gPEA-SH polymer brush.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com