Method and device for improving potato quality by electron beam irradiation of potato seed

A technology of electron beam irradiation and potato, applied in botany equipment and methods, plant genetic improvement, application, etc., can solve the problems of hard fried chips, high oil content, low output yield, etc., and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] The specific embodiment one, the method for improving potato quality by electron beam irradiation seed potato, its method is: irradiate potato seed potato with electron beam; Described electron beam is the charged particle that accelerator produces, and the dose of electron beam is between 1~6 Gray; dose rate range is 0.02 Gray / sec.

[0013] The irradiation process is done at room temperature.

[0014] The particle size of seed potato is 0.5cm-3cm, which is a defect-free and excellent variety seed potato.

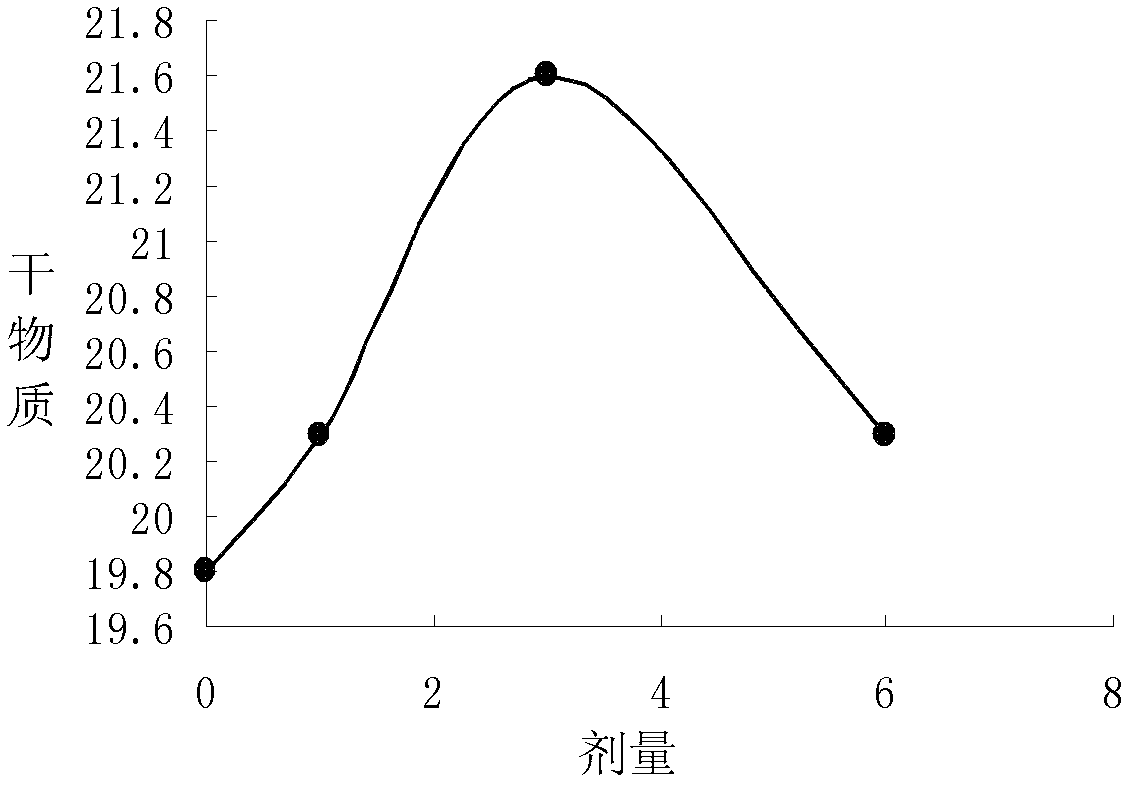

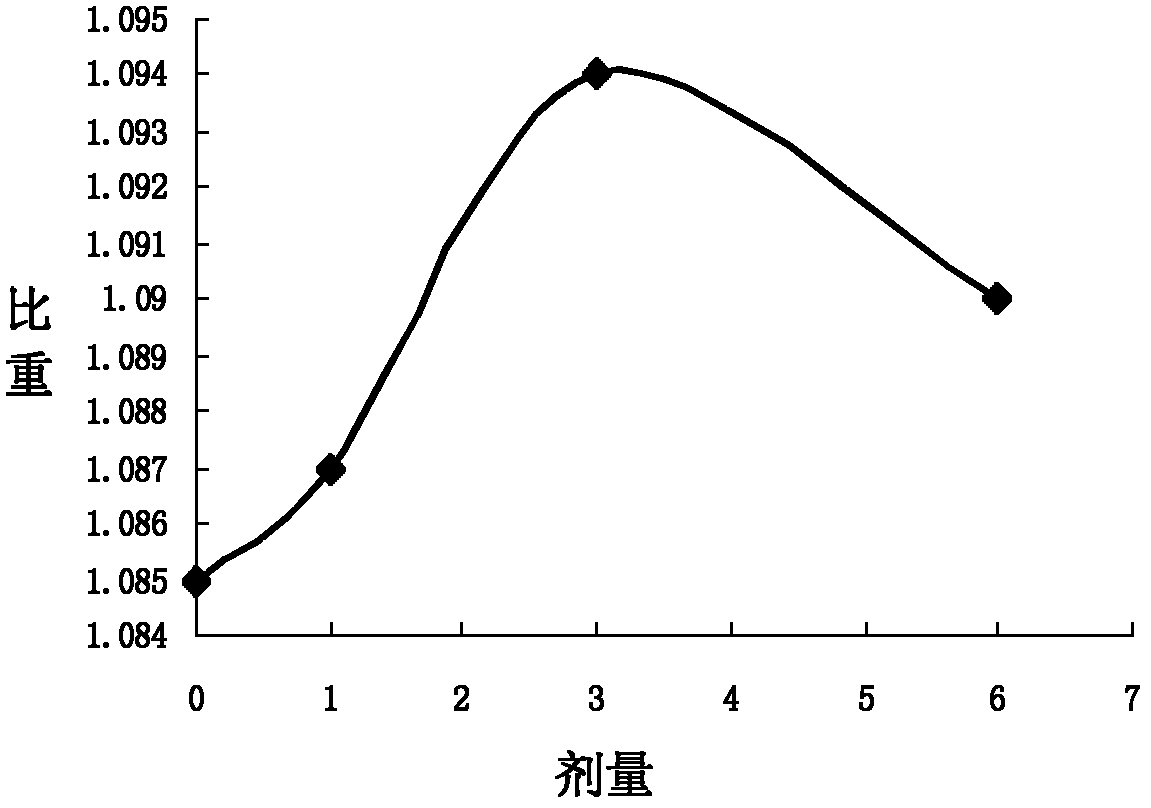

[0015] Select " Eugene " below, " sea potato No. 1 " kind, verify the effect of the present invention. Table 1 shows the quality change data of "Eugene" potato seed potatoes irradiated with different doses of electron beams, and Table 2 shows the quality change data of "Haishu No. 1" potatoes irradiated with different doses.

[0016] Table 1:

[0017] Dose (Gy)

0

1

3

6

dry matter %

19.8

20.3

21.6

20.3...

specific Embodiment approach 2

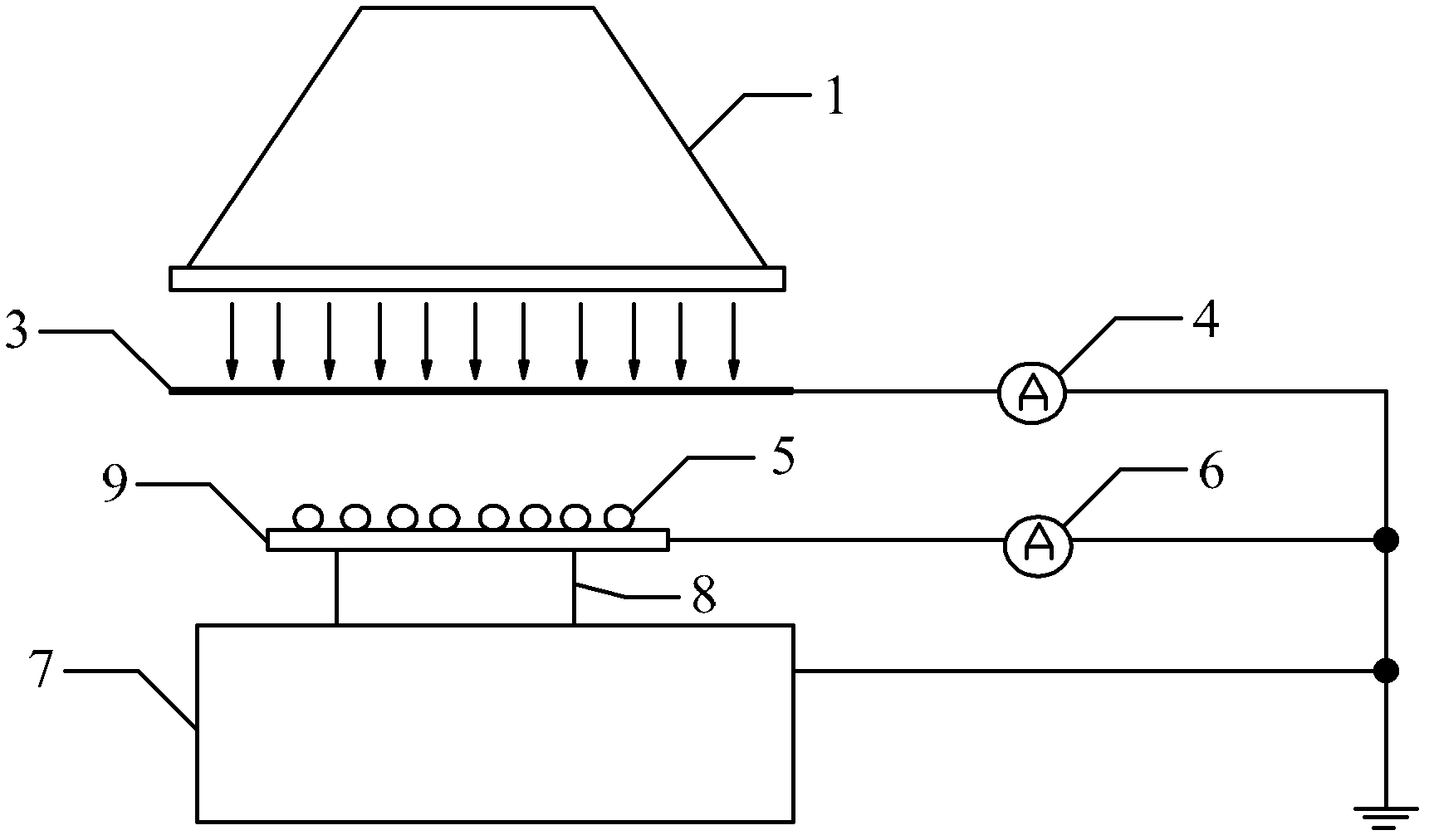

[0023] Specific embodiment two, combine figure 1 Illustrate this specific embodiment, the device that improves potato quality based on the electron beam irradiation seed potato of specific embodiment one, it comprises accelerator scanning box 1, metal plate 9 and insulating material body 8, the lower surface of metal plate 9 is fixed on insulating material On the upper surface of the body 8, the metal plate 9 is horizontally arranged, and the upper surface of the metal plate 9 is the placement area for the seed potato 5 to be irradiated, and the accelerator scanning box 1 is arranged directly above the metal plate 9, and The electron beam emitting surface of the accelerator scan box 1 faces the metal plate 9 .

[0024] When this embodiment is working, the potato seed potato 5 to be irradiated is placed on the metal plate 9, the area of the insulating material 8 is smaller than the area of the special metal plate 9, and the metal plate completely covers the insulating mater...

specific Embodiment approach 3

[0025] Embodiment 3. The difference between this embodiment and the device for improving potato quality by electron beam irradiating seed potatoes described in Embodiment 2 is that the electron beam emitted by the accelerator scanning box 1 is perpendicular to the horizontal plane where the metal plate 9 is located.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com