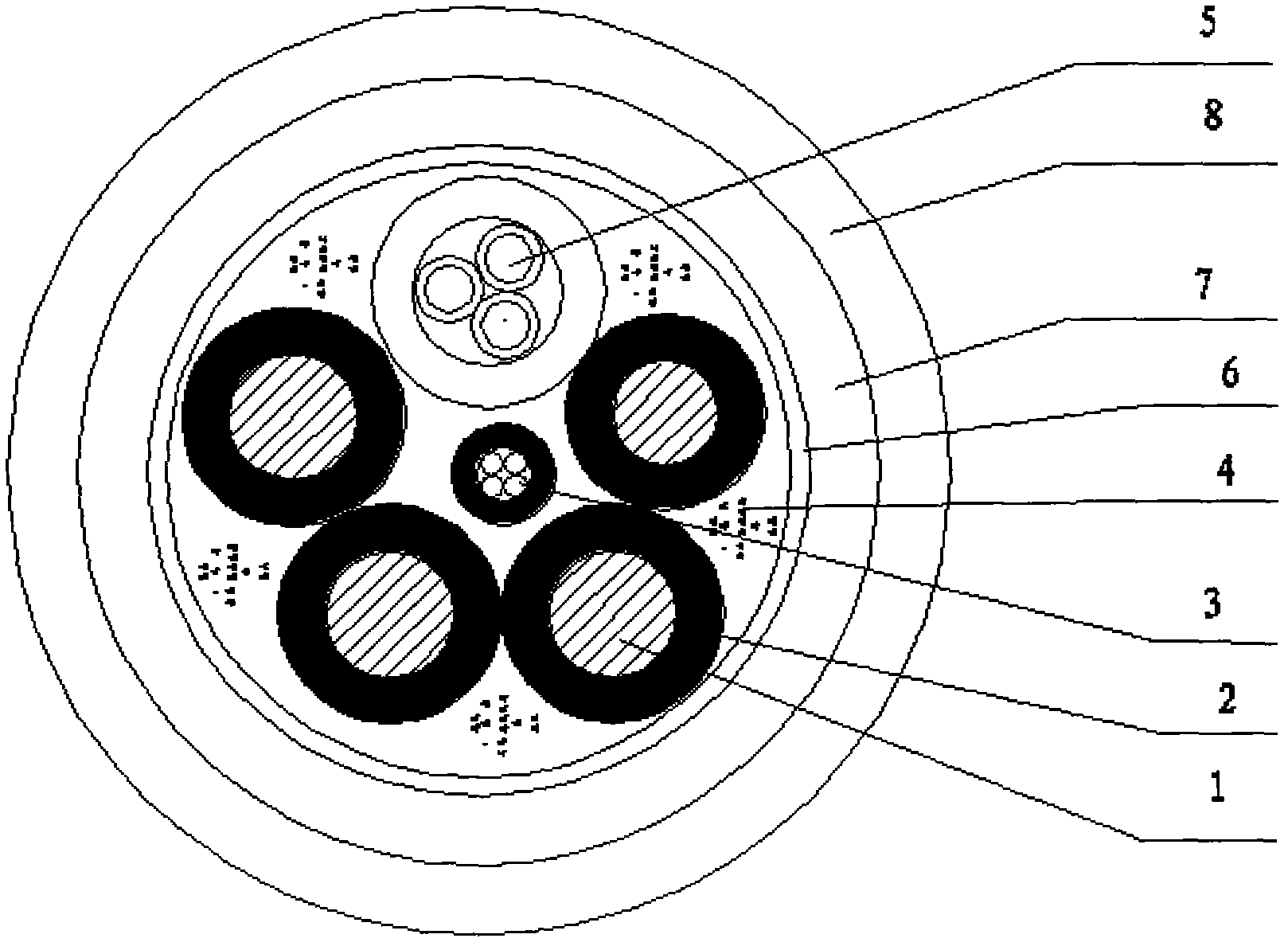

Optical-fiber composite low-voltage intelligent cable used in coal mine and preparation method thereof

A fiber optic composite, smart cable technology, applied in cable/conductor manufacturing, power cable, conductor/cable insulation, etc., can solve the problems of monitoring and management of electrical equipment that cannot be used, affecting communication functions, easy to break, etc., to ensure the line Integrity, enhance product function, ensure the effect of normal power-on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] According to the following methods, advanced equipment is used to manufacture optical fiber composite low-voltage intelligent cables for coal mines:

[0027] Wire drawing: the wire drawing adopts continuous drawing and continuous retreat middle drawing machine, the drawing speed is 12 m / s, the diameter of the copper conductor is 2.6mm, and the diameter of the outlet is 0.4mm;

[0028] Wire harness: JSH-500 wire harness machine is used, the pitch is controlled between 60-80, and the speed is 50 m / min;

[0029] Extruded insulation: Ethylene-propylene rubber is used to extrude the insulating layer; the extrusion die is an extrusion die, the length-to-diameter ratio of the extruder is 12, and the extrusion temperature: the feeding port is 30-45°C, and the head is 90- 100°C, the body temperature is 70-80°C, the screw speed is 15 rpm; the extrusion vulcanization temperature is 180-200°C;

[0030] Over-sparking: Using a power frequency spark machine, the relationship between ...

example 2

[0036] According to the following methods, advanced equipment is used to manufacture optical fiber composite low-voltage intelligent cables for coal mines:

[0037] Wire drawing: the wire drawing adopts continuous drawing and continuous retreat middle drawing machine, the drawing speed is 12 m / s, the diameter of the copper conductor is 2.6mm, and the diameter of the outlet is 0.4mm;

[0038] Wire harness: JSH-500 wire harness machine is used, the pitch is controlled between 90-100, and the speed is 70-80 m / min;

[0039] Extruded insulation: Ethylene-propylene rubber is used to extrude the insulating layer; the extrusion die is an extrusion die, the length-to-diameter ratio of the extruder is 12, and the extrusion temperature: the feeding port is 30-45°C, and the head is 90- 100°C, the body temperature is 70-80°C, the screw speed is 20 rpm; the extrusion vulcanization temperature is 180-200°C;

[0040] Over-sparking: Using a power frequency spark machine, the relationship betw...

example 3

[0046] According to the following methods, advanced equipment is used to manufacture optical fiber composite low-voltage intelligent cables for coal mines:

[0047] Wire drawing: the wire drawing adopts continuous drawing and continuous retreat middle drawing machine, the drawing speed is 12 m / s, the diameter of the copper conductor is 2.6mm, and the diameter of the outlet is 0.4mm;

[0048] Wire harness: JSH-500 wire harness machine is used, the pitch is controlled between 80-90, and the speed is 70-80 m / min;

[0049] Extruded insulation: Ethylene-propylene rubber is used to extrude the insulating layer; the extrusion die is an extrusion die, the length-to-diameter ratio of the extruder is 12, and the extrusion temperature: the feeding port is 30-45°C, and the head is 90- 100°C, the body temperature is 70-80°C, the screw speed is 25 rpm; the extrusion vulcanization temperature is 180-200°C;

[0050] Over-sparking: Using a power frequency spark machine, the relationship betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com