A control loop for variable filling pressure and its control method

A technology of control loop and control method, applied in pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of affecting production takt time, slow filling of equipment, poor filling accuracy, etc., and improve the filling takt time , Simple control, strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

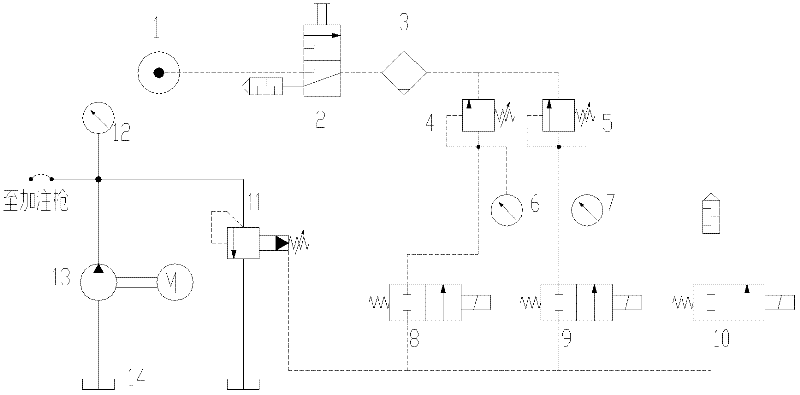

[0024] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0025] The idea of the present invention is: according to the characteristics of the filling process, the filling process is divided into two steps, (1) when starting to fill, because the automobile system pipeline is in a vacuum negative pressure state in advance, after a period of time, with Fluid filling, the pressure in the pipeline from negative pressure to normal atmospheric pressure, this section can be defined as "stage I". (2) Subsequently, as the fluid continues to be filled, the pressure in the automotive fluid pipeline rises from atmospheric pressure to the final filling pressure required by the process, and this section is defined as "Stage II". In the present invention, through loop control, high pressure is used for filling in phase I to increase the filling speed; in ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com