Mass adjustable counterweight for resonance crushers

A crusher and mass technology, applied in the direction of roads, road repair, roads, etc., can solve the problems such as the lack of buffer function of the counterweight and the vibrating parts, and the non-adjustable quality of the counterweight, so as to achieve isolated transmission, simplified structure and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

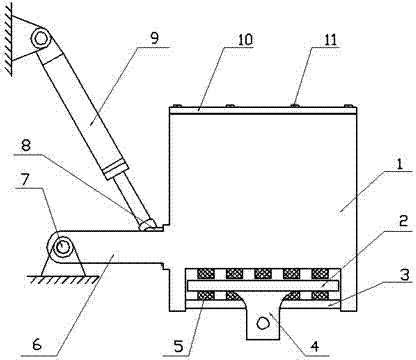

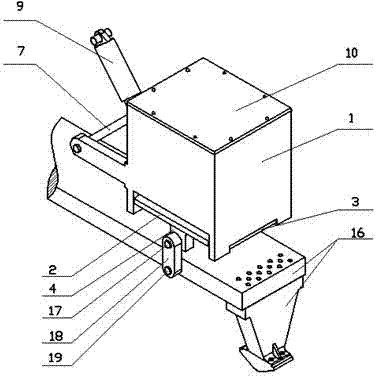

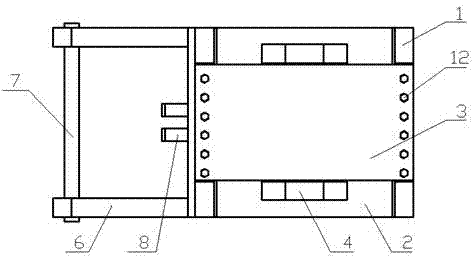

[0020] Now in conjunction with accompanying drawing, describe concrete structure of the present invention in detail.

[0021] Such as figure 1 As shown, the mass-adjustable counterweight device suitable for resonance crushers mainly includes counterweight box 1, carrier body 2, baffle plate 3, bearing lug 4, rubber strip 5, rocker arm 6, rocker shaft 7, lifting Lifting lug 8, hydraulic cylinder 9, counterweight box cover plate 10, weight block 14 and other parts; wherein the front end of rocking arm 6 is provided with rocking arm shaft 7, and rocking arm shaft 7 is installed on the vehicle frame support, and rocking arm 6 can be Rotate around it; the upper end of the hydraulic cylinder 9 is suspended on the frame column, and the lower end of the hydraulic cylinder is connected with the lifting lug 8 on one side of the counterweight box through a pivot pin. The expansion and contraction of the hydraulic cylinder 9 can make the counterweight box 1 rotate around the rocker shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com