A high-value utilization method of carbon dioxide in biogas

A biogas, high-value technology, applied in the field of utilization of carbon dioxide in biogas, can solve problems such as the failure to achieve CO2 recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

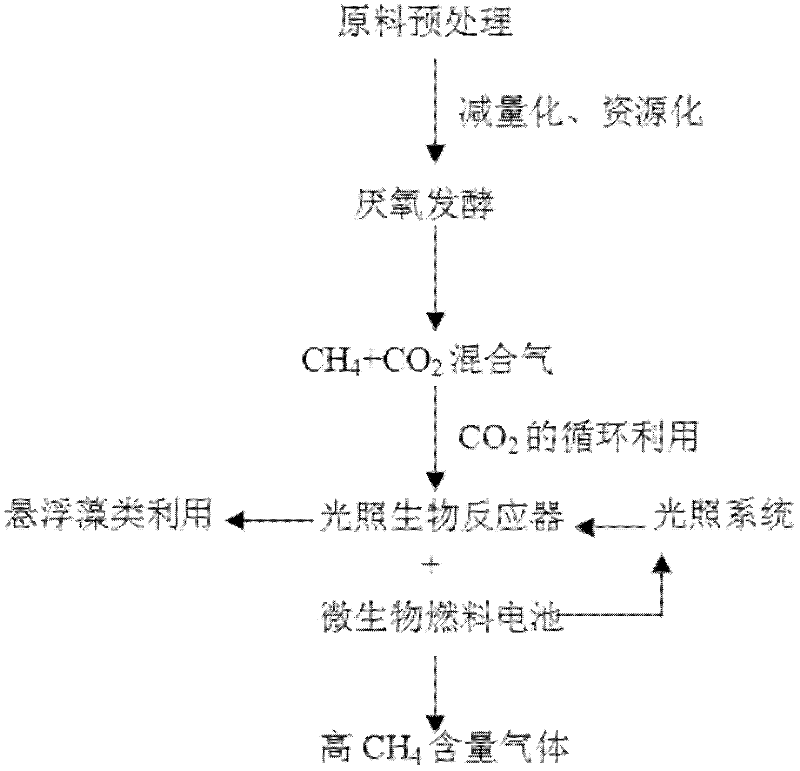

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Anaerobic fermentation and CO with energy grass as raw material2 High Value Utilization System

[0036] (1) Pretreatment of energy grass: the energy grass after mowing is crushed with a crusher so that the length of the raw material is between 1-2 cm, and the crushed raw material is treated with 2% concentration of alkali at 50°C for 6 hours, and the alkali method It can neutralize the acid produced in the acid production stage, adjust the pH of the raw material solution to about 7.0, and avoid acid inhibition caused by excessive acid accumulation to a certain extent.

[0037] (2) Anaerobic fermentation: the pretreated raw materials are fed into the reactor through a screw feeding method, and the anaerobic fermentation is carried out by adopting the method of medium temperature continuous feeding and continuous discharging, and the temperature of the anaerobic fermentation is 35-55°C. Ammonium bicarbonate is added as a pH buffer, the pH is controlled at 7.0-7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com