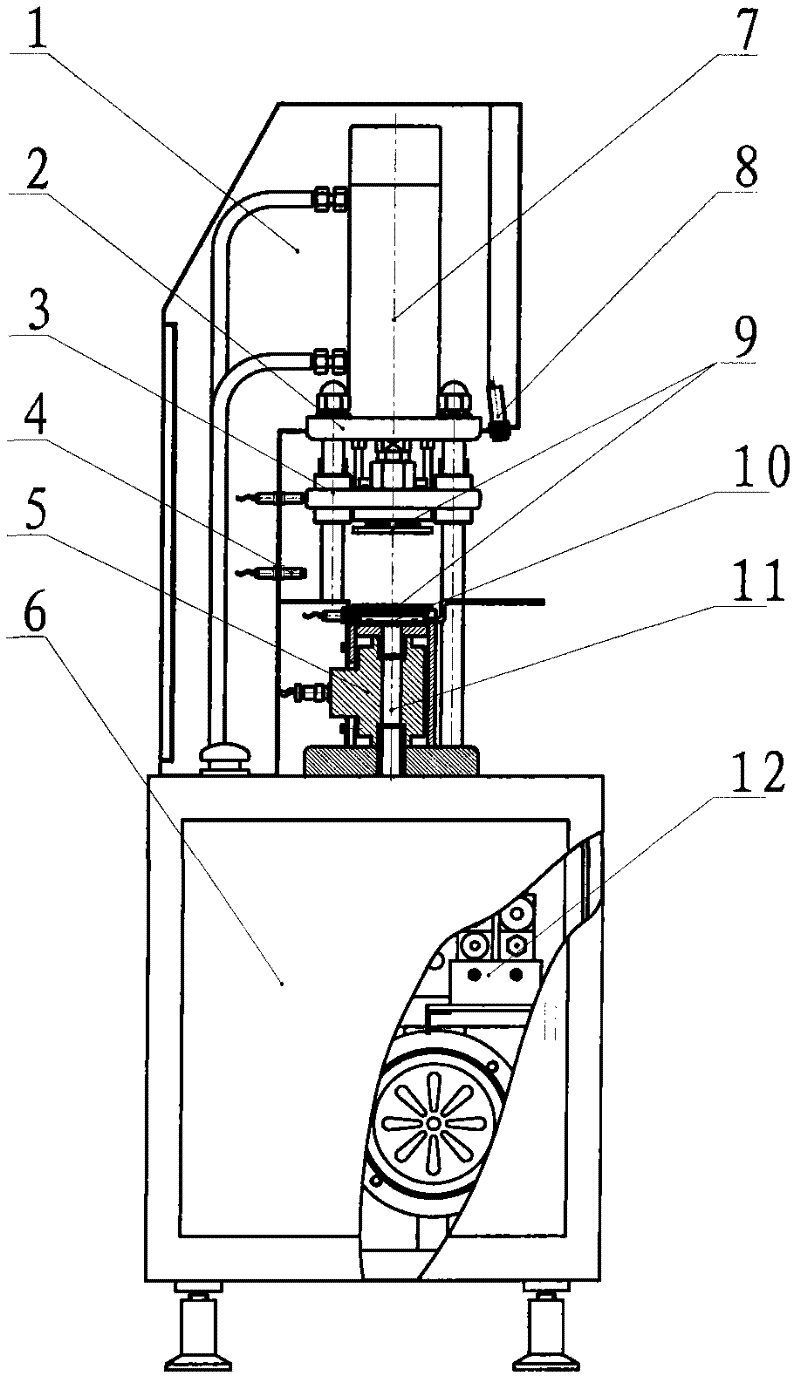

A drug pressing machine for preparing small-diameter granular implants

An implant, granular technology, applied in the direction of material molding presses, presses, manufacturing tools, etc., to achieve the effect of reducing pollution, good safety performance, easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

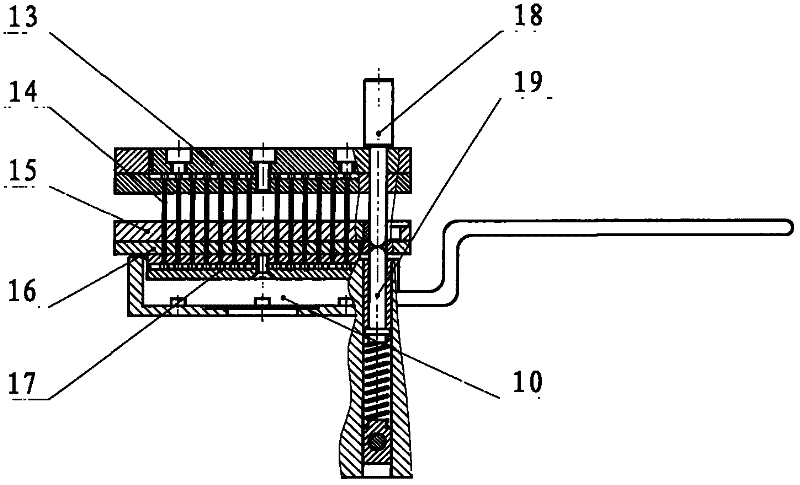

Method used

Image

Examples

Embodiment Construction

[0021] First, the powdery raw material is quantitatively added into the porous forming mold through vibration, and then the forming mold is put into the mold base to fix the position. Start the equipment, set the process operation parameters such as pressing pressure and pressure holding time, and the mold is completely closed under the automatic control of the control system. After holding the pressure for a certain period of time, the ejector mechanism ejects the implant particles and collects them in a vacuum under the action of vacuum. Then open the mold to the upper limit position, take out the template, and complete a working cycle.

[0022] The above are only preferred embodiments of the present invention, and it should be pointed out that those skilled in the art can make several modifications and improvements without departing from the inventive concept of the present invention, and these all belong to the present invention. scope of protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com