Welding method for support rack of nuclear reactor evaporator

A welding method and technology for nuclear reactors, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficulty in ensuring weld quality, lack of assembly sequence, and inability to effectively control welding deformation, to prevent shrinkage deformation and ensure welding. The effect of seam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

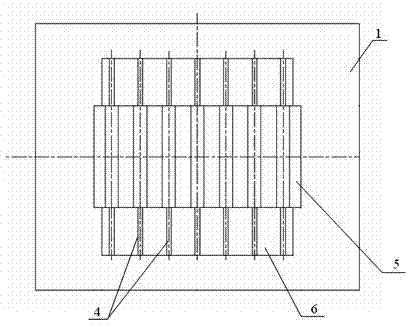

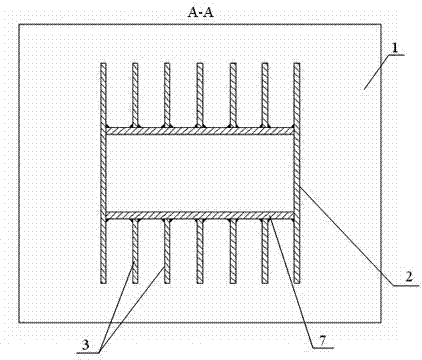

[0039] See also Figure 1 to Figure 4 As shown in the figure, the welding method of the support bracket of the nuclear reactor evaporator according to the present invention may be the bottom plate 1 and the middle partition plate 6 arranged horizontally on the support bracket, and the first plurality of first plates arranged vertically between them. The lower-layer longitudinal support plate 2, the second lower-layer longitudinal support plate 3 and the lower-layer transverse support plate 7 are connected to form a frame.

[0040] The welding method of the present invention is used to control the quality of the full penetration weld between several upper longitudinal support plates 4, the top plate 5 above, and the middle partition plate 6 below.

[0041] Specifically includes the following steps:

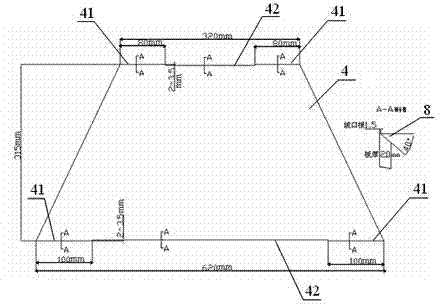

[0042] step 1, as Figure 5 As shown, the blanking shapes of the plurality of upper longitudinal support plates 4 are obtained, and grooves 8 are processed at the welding position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com