A method for controlling the weld seam formation of Hass alloy conductive roller laser penetration welding

A technology of welding seam forming and control method, which is applied in the laser welding of I-type groove thick-walled Haas alloy materials and the laser penetration welding of Haas alloy conductive rollers in the field of seam forming control, which can solve the problem of large welding residual stress and lack of fusion. , reduce the corrosion resistance of welds, etc., to achieve the effect of ensuring technical indicators, small beam diameter, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

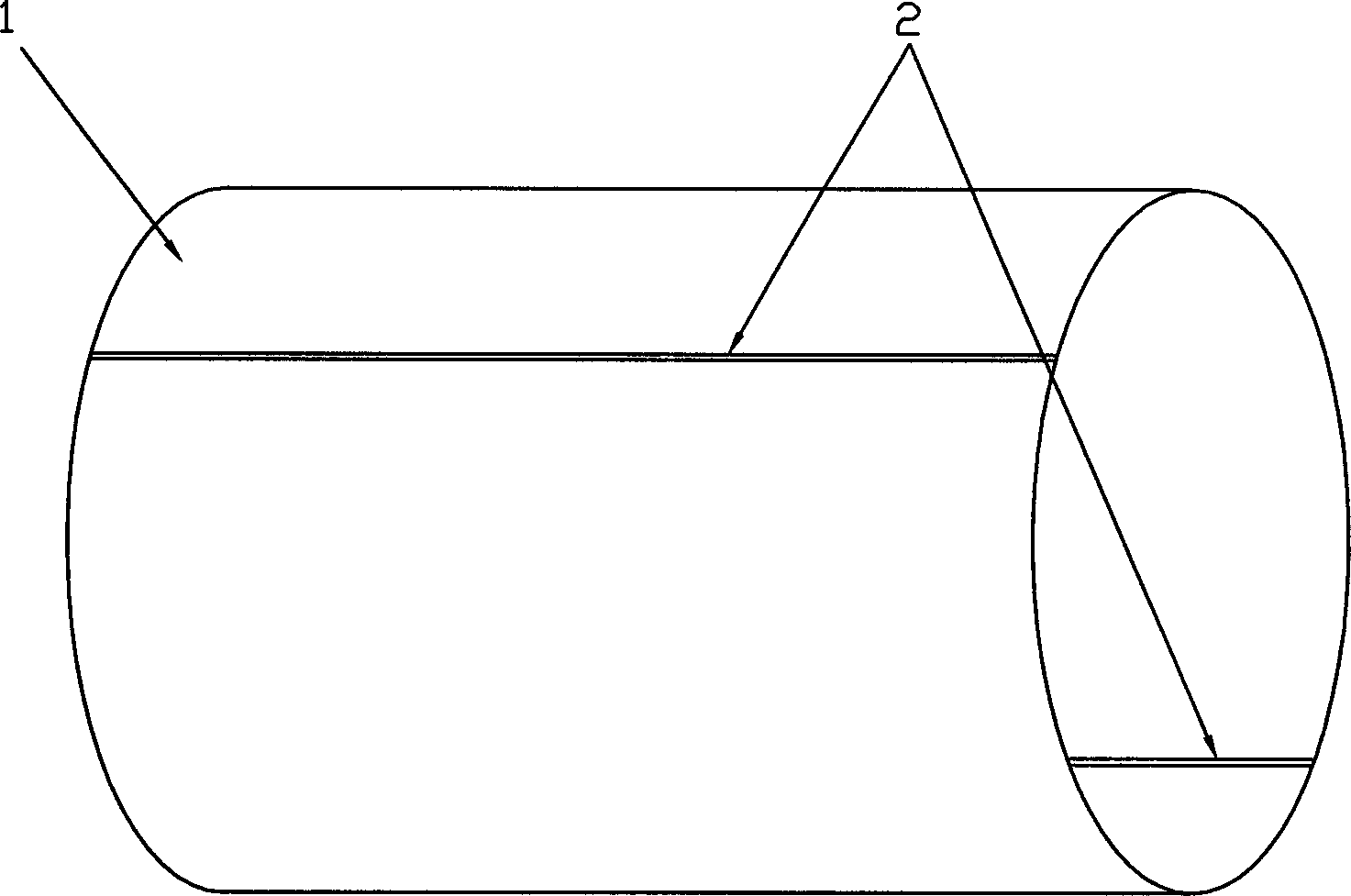

[0026] In this embodiment, the present invention is used for laser welding the conductive roller of the hastealloy alloy cylinder casing structure, the plate butt joint or the cylinder longitudinal seam are all laser penetration welded, the shape of the Hastealloy alloy cylinder and the arrangement of the welding seam. It adopts I-type joint form, no need to add filler metal to the weld seam, and double-sided forming in one welding. A gantry five-axis CO 2 The laser welding machine is used for the welding of Hass alloy plate butt joints and cylinder butt joints. The laser welding machine is controlled by software programming on the control platform, and the three-dimensional space position coordinates of the laser welding torch are adjusted to realize the height tracking of the laser welding torch relative to the weld seam and the centering of the laser beam and the center line of the weld seam.

[0027] In this embodiment, the welding process parameters are fixed: the laser ...

Embodiment 2

[0029] In this embodiment, the present invention is used for laser welding the conductive roller of the hastealloy alloy cylinder casing structure, the plate butt joint or the cylinder longitudinal seam are all laser penetration welded, the shape of the Hastealloy alloy cylinder and the arrangement of the welding seam. I-type joints are adopted, and the 10.5mm thick Hass alloy steel plate does not need to be grooved, and there is no need to add filler metal to the weld, and it can be formed on both sides in one welding. A gantry five-axis CO 2 The laser welding machine is used for the welding of Hass alloy plate butt joints and cylinder butt joints. The laser welding machine is controlled by software programming on the control platform, and the three-dimensional space position coordinates of the laser welding torch are adjusted to realize the height tracking of the laser welding torch relative to the weld seam and the centering of the laser beam and the center line of the weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com