A method for on-site sampling and pollution degree measurement of insulator pollution

A measurement method and insulator technology, applied in the direction of removing a certain component weighing, sampling device, and preparation of test samples, etc., can solve the deviation of pollution collection methods, insulator removal, inconvenient handling, and the impact of experimental results, etc. problems, to achieve standardized and reasonable measurement process, avoid pollution loss, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The method of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] The on-site sampling method for insulator pollution of the present invention comprises the following steps:

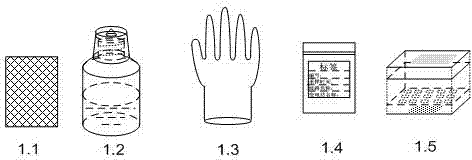

[0033] Step 1. Prepare the insulator pollution sampling kit, such as figure 1 As shown, including sampling cloth, wetting agent, sampling gloves, collection bag and sample box, wherein the sampling cloth is non-woven fabric, for 300 ml The conductivity value of deionized water is not affected by more than 5 μs / cm ; The wetting agent has a conductivity of less than 5 μs / cm deionized water; the sampling gloves are plastic gloves; as a specific embodiment, the sample box 1.5 is made of engineering plastics, which is not deformed under heavy pressure, and the sample box has two layers, the upper layer is a sample placement area, and the bottom layer is an isolation The desiccant is placed in the isolation layer, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com