The production method of accelerator n-tert-butyl-2-benzothiazole sulfenamide

The technology of a benzothiazole sulfenamide and a production method is applied in the production field of the accelerator NS process, which can solve the problems of increasing the amount of waste water and increasing the production cost, and achieve the effects of reducing the discharge of waste water and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] 1. Add 32.5g of accelerator M to 100ml of water, add 2ml with a concentration of 7% to add a total of 125ml, and make up to 125ml when the volume is insufficient (the first batch of water will be used to make up, and the mother liquor will be used to replace water to make up later), and put it into a container with volume Reserve in a graduated container.

[0016] 2. Put 100ml of sodium hypochlorite with 18.4-18.6g / 100ml of available chlorine and 0.8-1g / 100ml of free alkali into a container with volume scale for later use.

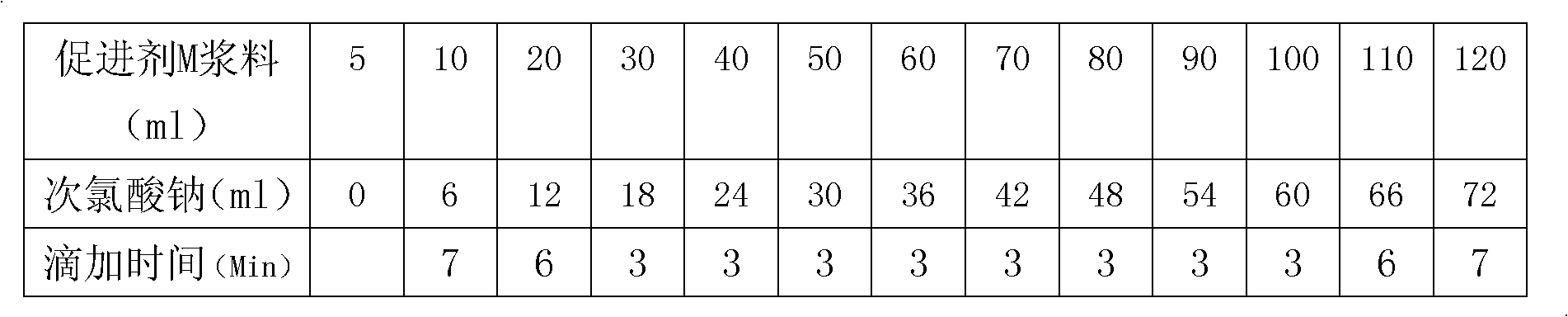

[0017] 3. First put 15g (21.7ml) of tert-butylamine into a 300ml reaction vessel, stir and heat up to 43-45°C, then add 5ml of accelerator M slurry as a base material, and then add accelerator M slurry and sodium hypochlorite by The volume ratio is 5:3 for dropwise addition, and the dropwise addition needs to be completed within 45-55 minutes, and the temperature during the dropwise addition cannot be higher than 45°C.

[0018] Add 15g of tert-buty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com