A kind of method that utilizes passion fruit pomace to produce organic fertilizer

A technology of passionflower and organic fertilizer, applied in the field of organic fertilizer produced by this method, can solve the problems of thick waxy layer and low pH value, and achieve the effect of shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

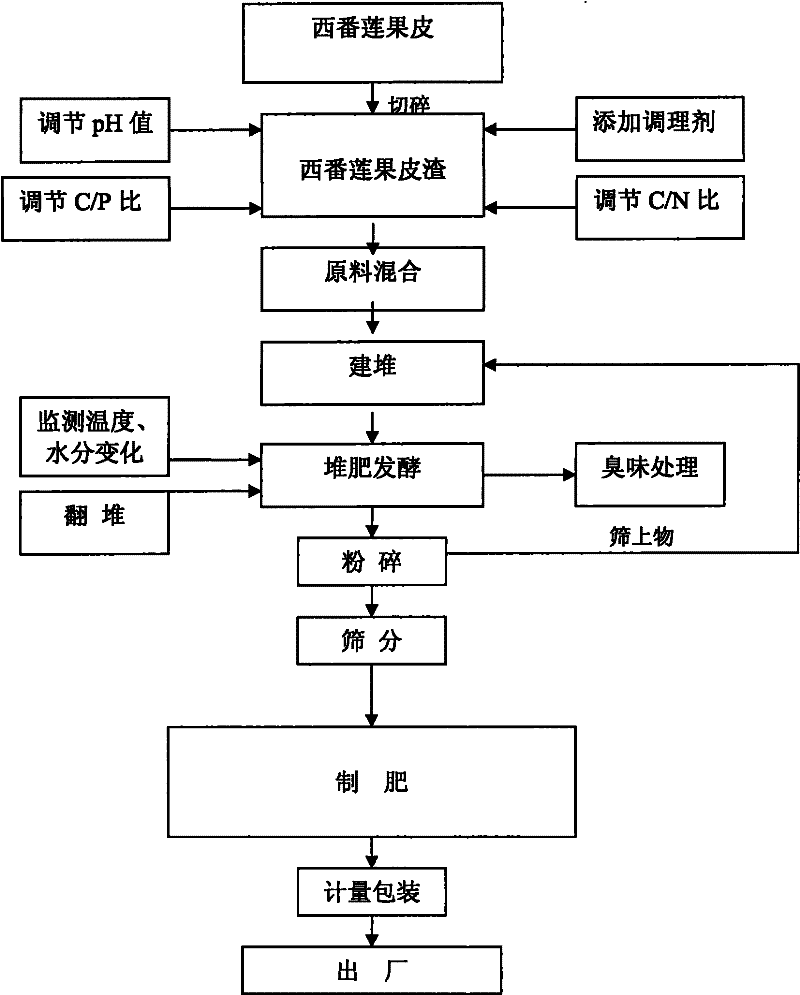

Method used

Image

Examples

Embodiment 1

[0024] Implementation location: the planting base of Jiangcheng Green Banna Ecological Food Co., Ltd., Kangping Township, Jiangcheng County, Puer City, Yunnan Province.

[0025] Implementing materials: passion fruit pomace, cow dung

[0026] The fermentation method that the present invention utilizes passion fruit peel dregs to produce organic fertilizer specifically comprises the following steps:

[0027] 4 tons of passion fruit pomace are pulverized to particle size and are 1~3cm, adjust pH value to 6.5 with the quicklime that is equivalent to 0.5% of pericarp weight, add according to cow dung: passion fruit pomace is 1: 9 (weight ratio) For cow dung, adjust the C / N ratio to 32, and adjust the C / P ratio to 100:1 with phosphate rock powder once composting begins. Add organic material decomposing agent (Beijing Wotu Tiandi Biotechnology Co., Ltd., Microbial Fertilizer (2006) Linzi (0503) No.) according to the weight ratio of 0.3% before composting.

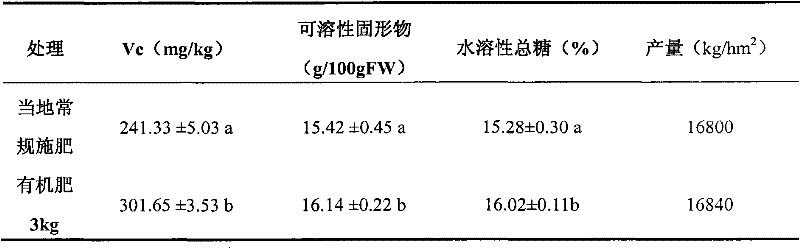

[0028] compost fermentat...

Embodiment 2

[0031] Implementation location: the planting base of Jiangcheng Green Banna Ecological Food Co., Ltd., Kangping Township, Jiangcheng County, Puer City, Yunnan Province.

[0032] Implementing materials: passion fruit pomace, cow dung

[0033] The fermentation method that the present invention utilizes passion fruit peel dregs to produce organic fertilizer specifically comprises the following steps:

[0034] 3 tons of passion fruit pomace are pulverized to particle size and are 1~3cm, adjust pH value to 6.5 with the quicklime that is equivalent to 0.5% of pericarp weight, add according to cow dung: passion fruit pomace is 2: 8 (weight ratio) For cow dung, adjust the C / N ratio to 27, and adjust the C / P ratio to 85:1 once composting begins. Add organic material decomposing agent (about 1.0×10 Bacillus subtilis) according to the weight ratio of 0.2% before composting begins 9 cfu / g, Bacillus licheniformis about 1.0×10 9 cfu / g, Bacillus polymyxa about 1.0×10 9 cfu / g, brewer's ye...

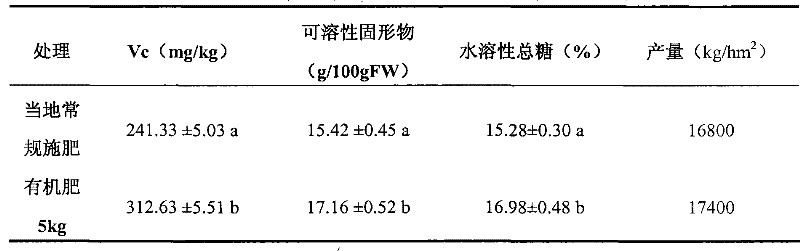

Embodiment 3

[0038] Implementation location: the planting base of Jiangcheng Green Banna Ecological Food Co., Ltd., Kangping Township, Jiangcheng County, Puer City, Yunnan Province.

[0039] Implementing materials: passion fruit pomace, cow dung

[0040] The fermentation method that the present invention utilizes passion fruit peel dregs to produce organic fertilizer specifically comprises the following steps:

[0041] 4 tons of passion fruit pomace are pulverized to particle size and are 1~3cm, adjust pH value to 6.5 with the quicklime that is equivalent to 0.5% of pericarp weight, add according to cow dung: passion fruit pomace is 3: 7 (weight ratio) For cow dung, adjust the C / N ratio to 25, and adjust the C / P ratio to 75:1 once composting begins. Add organic material decomposing agent (about 1.0×10 Bacillus subtilis) according to the weight ratio of 0.2% before composting begins 9 cfu / g, Bacillus licheniformis about 1.0×10 9 cfu / g, Bacillus polymyxa about 1.0×10 9 cfu / g, brewer's ye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com