Box girder flipping method

A box girder and overturning tire frame technology is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of box girder structure damage, large overturning force, and difficulty in overturning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

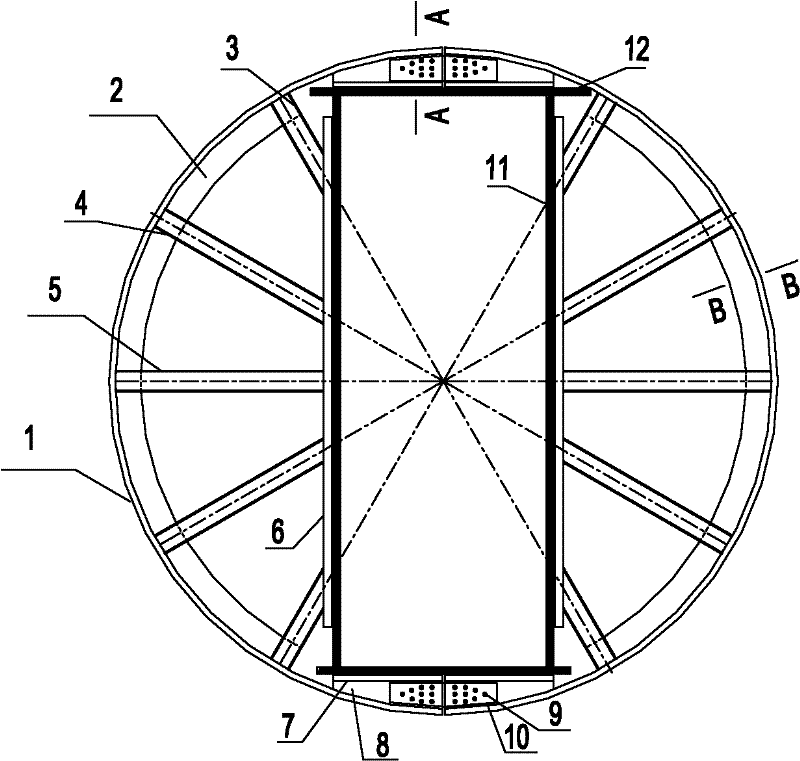

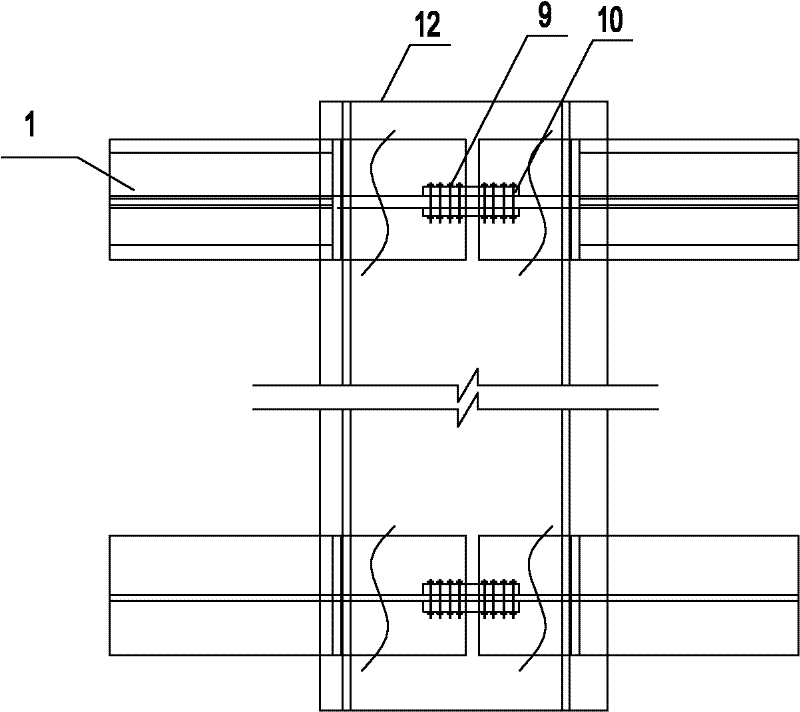

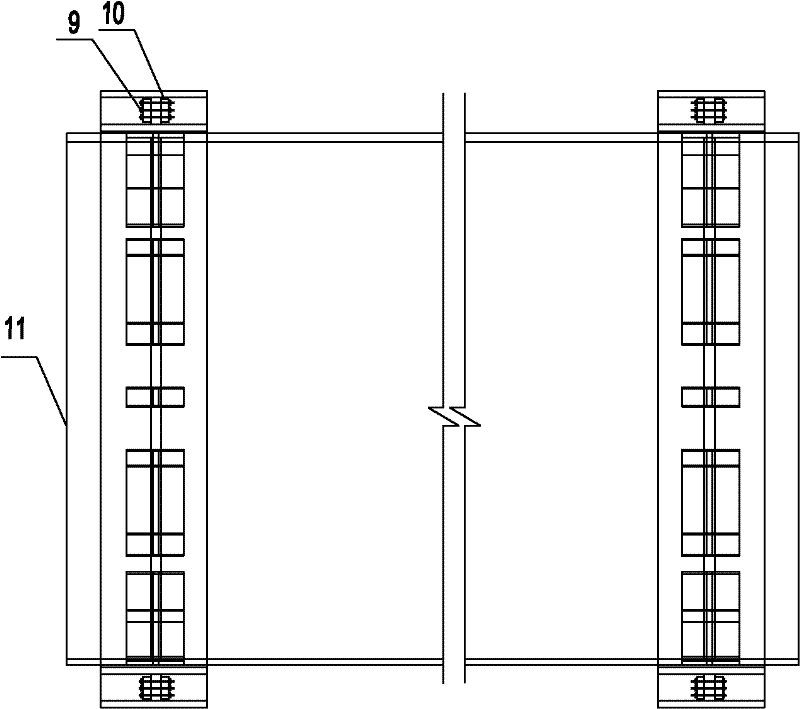

[0033] A method for overturning a box girder, comprising the steps of:

[0034] Step 1. Preparation before operation:

[0035] 1.1 Design of the overturn tire frame scheme

[0036] According to the weight and peripheral dimensions of the box girder components, the capacity and height of the lifting equipment, design and manufacture at least two overturned tire racks;

[0037] 1.2 Lift one end of the assembled box girder, use H-shaped steel to raise the box girder, and then lift the other end, and also use H-shaped steel to raise the box girder, so that the whole section of the box girder is carried by two shaped steel; When it is high, the height is greater than the distance from the flange surface of the inverted tire frame to the outer end of the T-beam;

[0038] Step 2, formal operation:

[0039] 2.1 Put the two overturned tire racks on the left and right ends of the box girder respectively, tighten the bolts, then hoist the two ends of the box girder in sequence with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com