Tensionable linear sieve

A tensioned, sieve plate technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of low opening rate, poor elasticity of the sieve plate, deterioration of the screening process, etc., to achieve convenient replacement and maintenance, open The effect of high porosity and high sieving rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

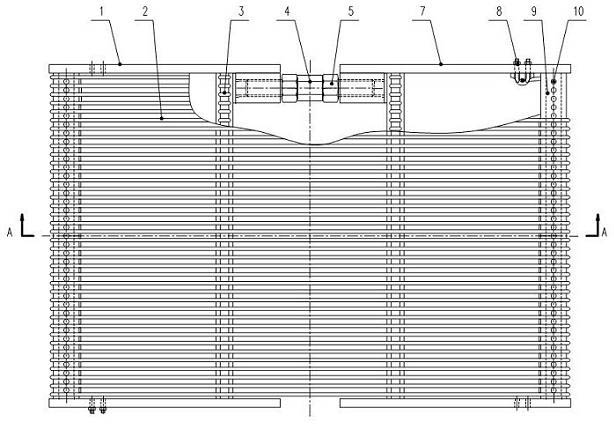

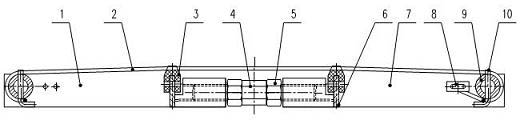

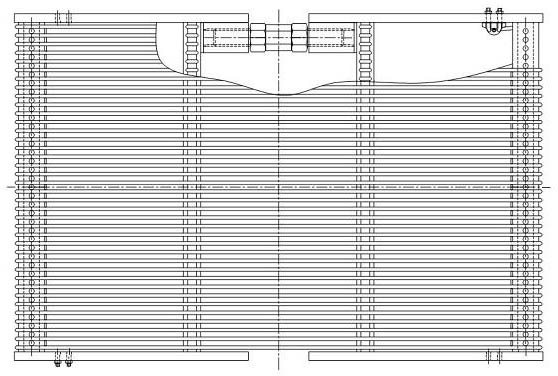

[0009] An embodiment of the present invention will be described below in conjunction with the accompanying drawings. It is mainly composed of sieve plate frame, sieve bar, sieve bar support and tensioning device. Its external dimensions are 610mm×590mm. The sieve plate frame is composed of the left sieve plate frame 1 and the right sieve plate frame 7, and the left and right sieve plate frames are connected together by two sets of tension bolts, adjusting nuts 4 and lock nuts 5; at the left end of the left sieve plate frame 1 And the right end of the right sieve plate frame 7 is provided with a sieve bar end locking member 8 and a round tube 9 for fixing the sieve bar. The round tube 9 is provided with 56 equidistant positioning columns 10; in the middle of the sieve plate frame The position is provided with a sieve bar support beam 6, and a support positioning bar 3 is installed on the top of the sieve bar support beam 6; the support positioning bar 3 is processed with equid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com