Method for determining the stability of sirolimus and process for preparing stable forms thereof

A sirolimus, form technology, applied in the field of preparing stable forms of sirolimus or sirolimus analogues, can solve problems such as inability to apply crystallinity measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

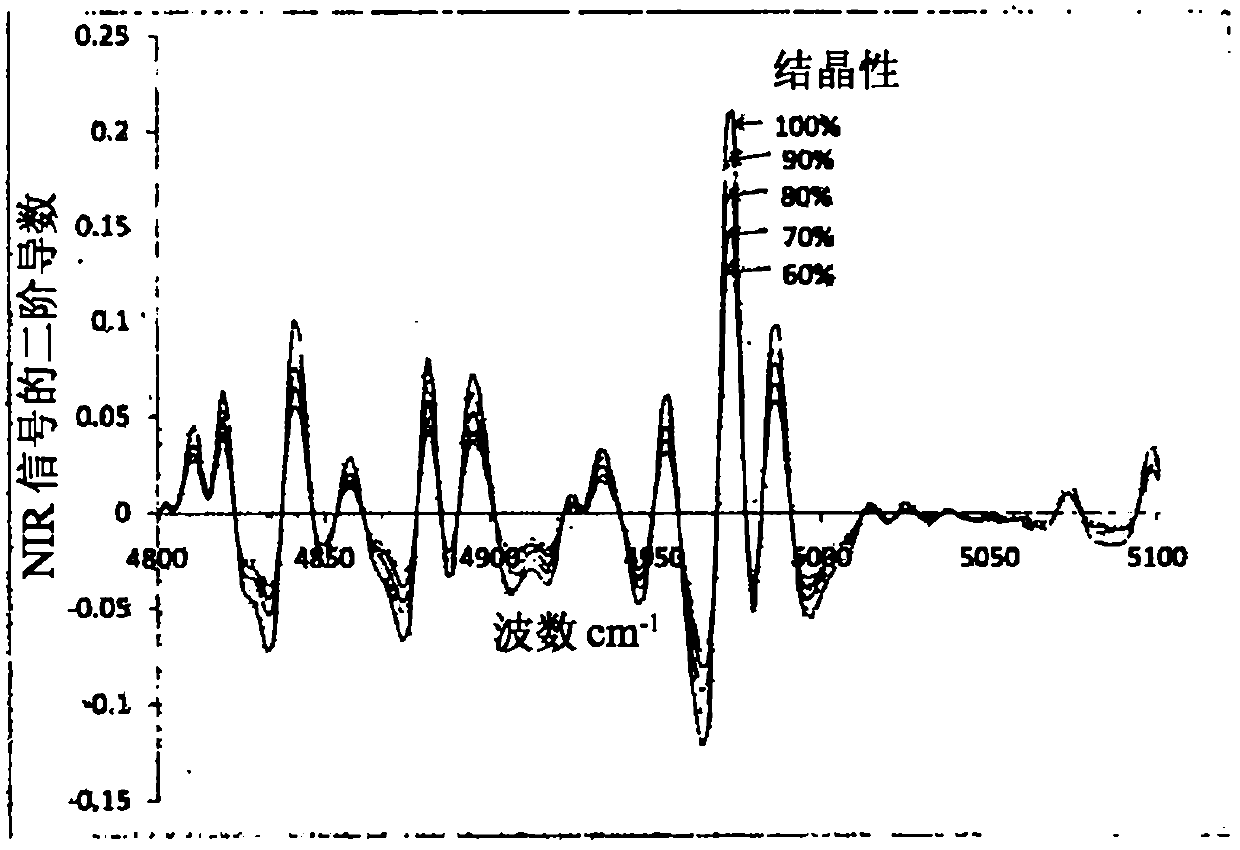

[0038] NIR Spectroscopy for Determination of Sirolimus Crystallinity

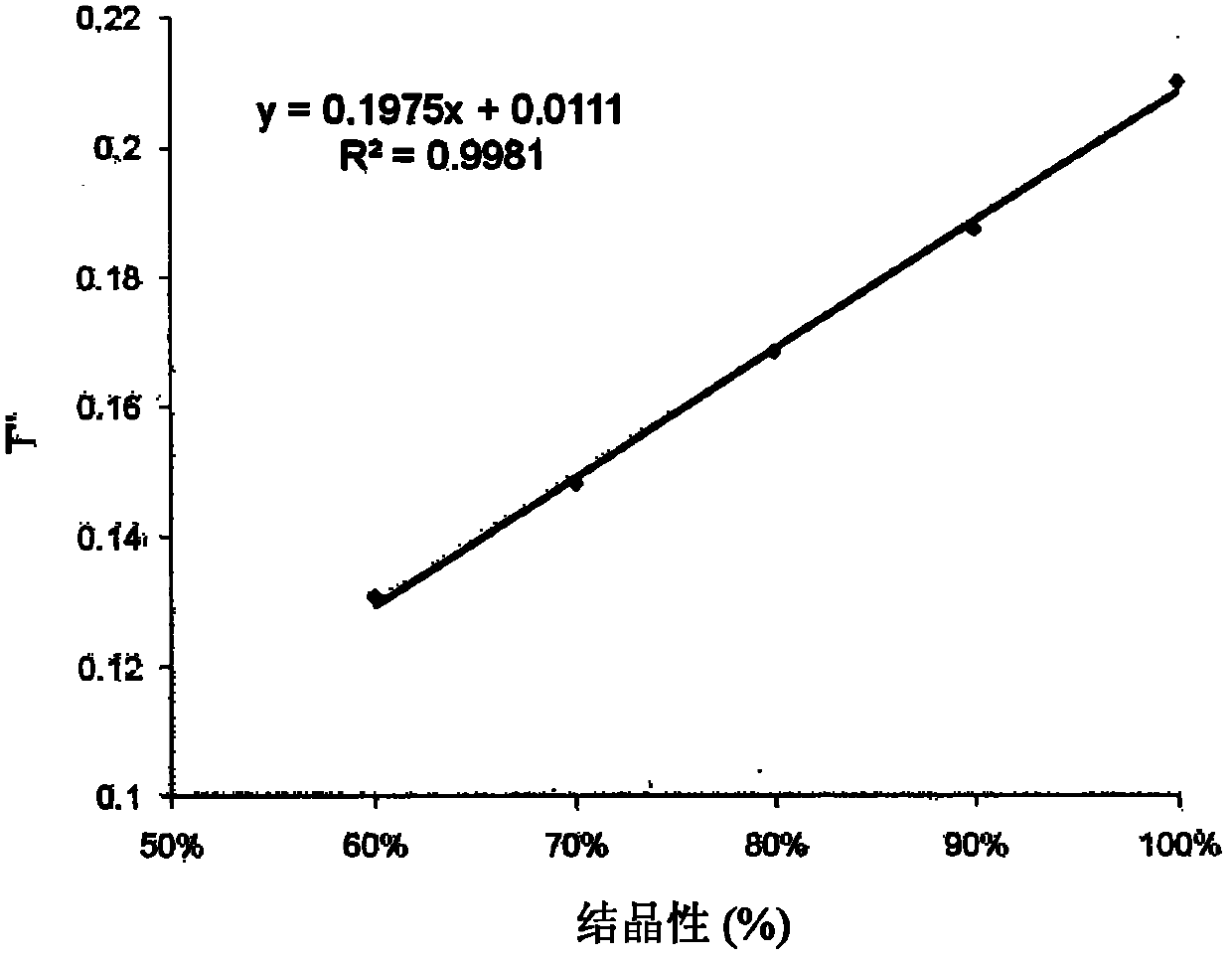

[0039] Amorphous sirolimus and crystalline sirolimus were mixed in different proportions. The NIR spectrum of the obtained sample was measured using a NIR spectrophotometer. The spectrum is processed by taking the second derivative of the spectrum (see figure 1 ). Sirolimus samples with different crystallinity at 4973.6cm -1 The second derivative value at wavenumber (T") is plotted against crystallinity. Linear regression of this data yields the following equation:

[0040] T"=0.1975×crystallinity+0.0111R 2 =0.9981

[0041] In order to determine the crystallinity of a test sample, the NIR spectrum of the sample is measured and its second derivative is obtained. Will be at 4973.6cm -1 The second derivative at the wave number was substituted into the above equation to obtain the crystallinity of the test sample, which was found to be 99%.

Embodiment 2

[0043] Sirolimus crystallization

[0044] A 130 ml ethyl acetate layer containing 15 g sirolimus was charged into a 650 ml stirred vessel. The temperature of the solution was maintained at about 25°C. To this solution was added 260 ml of n-heptane at a rate of 0.54 ml / min with stirring. After the addition was complete, the mixture was kept under stirring for 12 hours. The crystals formed were filtered and dried under vacuum for 48 hours. These crystals were analyzed by NIR spectroscopy according to the method described in Example 1. The degree of crystallinity of the crystals was measured to be 100%.

Embodiment 3

[0046] Sirolimus crystallization

[0047] 10 g of sirolimus was dissolved in 68 ml of acetonitrile at 25°C. To this solution was added 204 ml of water at a rate of 0.425 ml / min with stirring. After the addition was complete, the mixture was kept under stirring for 12 hours. The crystals formed were filtered and dried under vacuum for 24 hours. Crystals were analyzed by NIR spectroscopy according to the method described in Example 1. The degree of crystallinity of the crystals was measured to be 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com