Circuit board, circuit board assembly and semiconductor device

A technology for circuit boards and semiconductors, applied in semiconductor devices, printed circuit parts, circuits, etc., can solve problems such as the inability to reduce the stress at the joints of raised electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

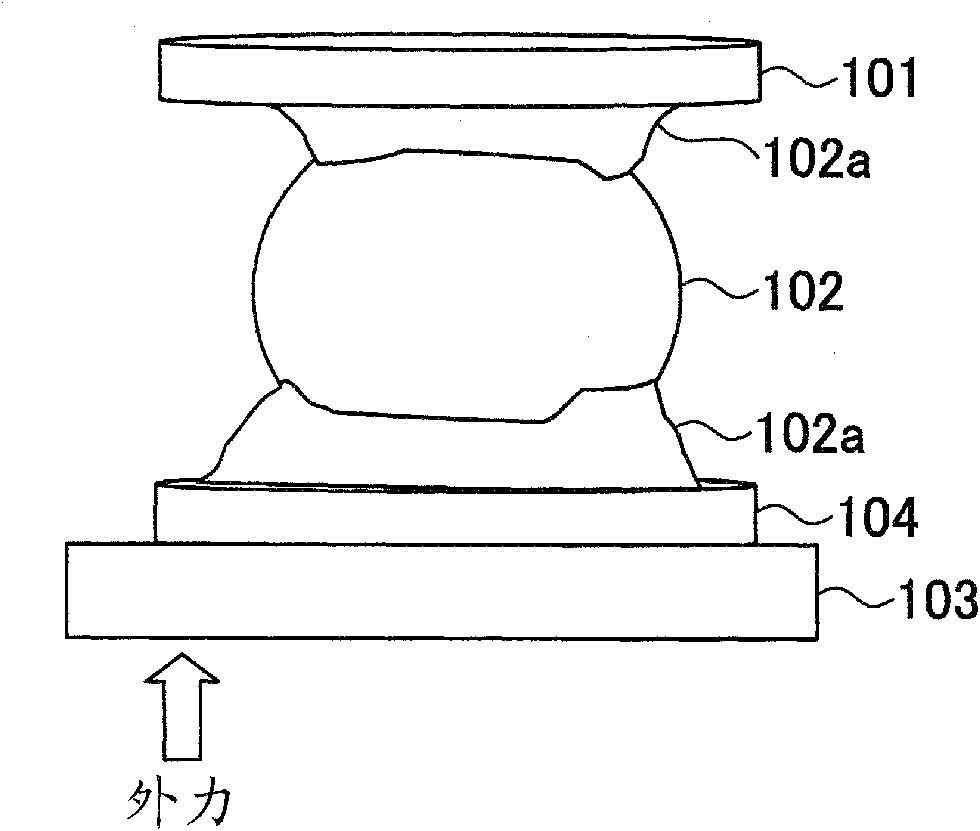

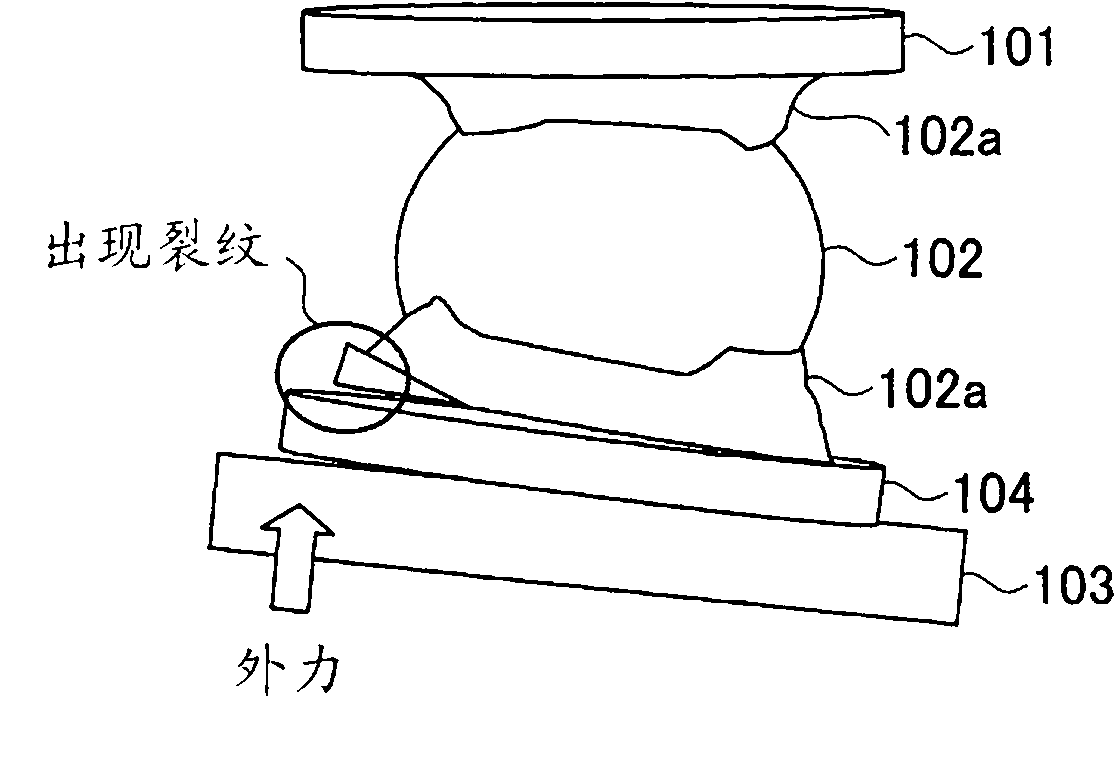

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

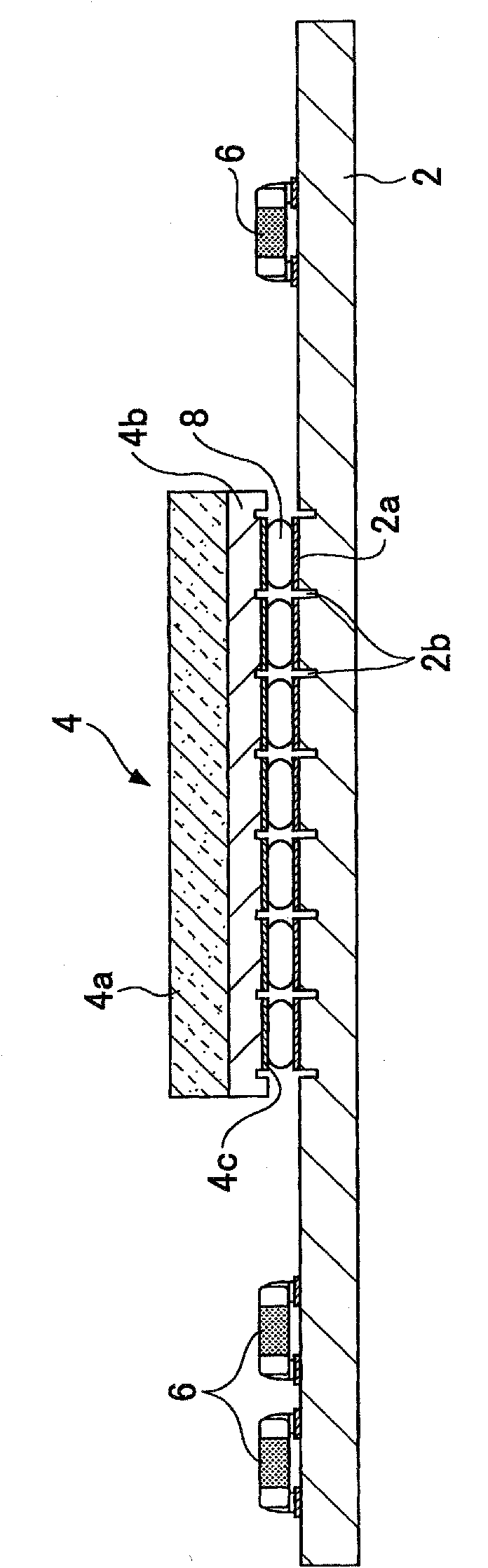

[0032] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0033] figure 2 is a cross-sectional view of a circuit board assembly according to one embodiment of the present invention. Such as figure 2 As shown, the circuit board assembly includes a circuit board 2 , a semiconductor device 4 and a passive device 6 (such as a resistor, a capacitor, etc.), so that the semiconductor device 4 and the passive device 6 are mounted on the circuit board 2 . The circuit board 2 includes wiring both on its surface and inside. The semiconductor device 4 includes an electrode 4c. The electrodes 4c are bonded to the corresponding electrode pads 2a of the circuit board 2 through solder bumps 8 as bonding members.

[0034]The circuit board 2 is, for example, a multi-layer board formed by using an organic board (such as glass epoxy resin). On the surface of the circuit board 2, electrode pads 2a for mounting the semiconductor device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com