Supporting device for lens in lithography projection objective lens

A supporting device and lithographic projection technology, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, installation, etc., can solve the problems of reducing the surface shape accuracy of the lens, and achieve reliable positioning, support isolation, and easy processing and manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

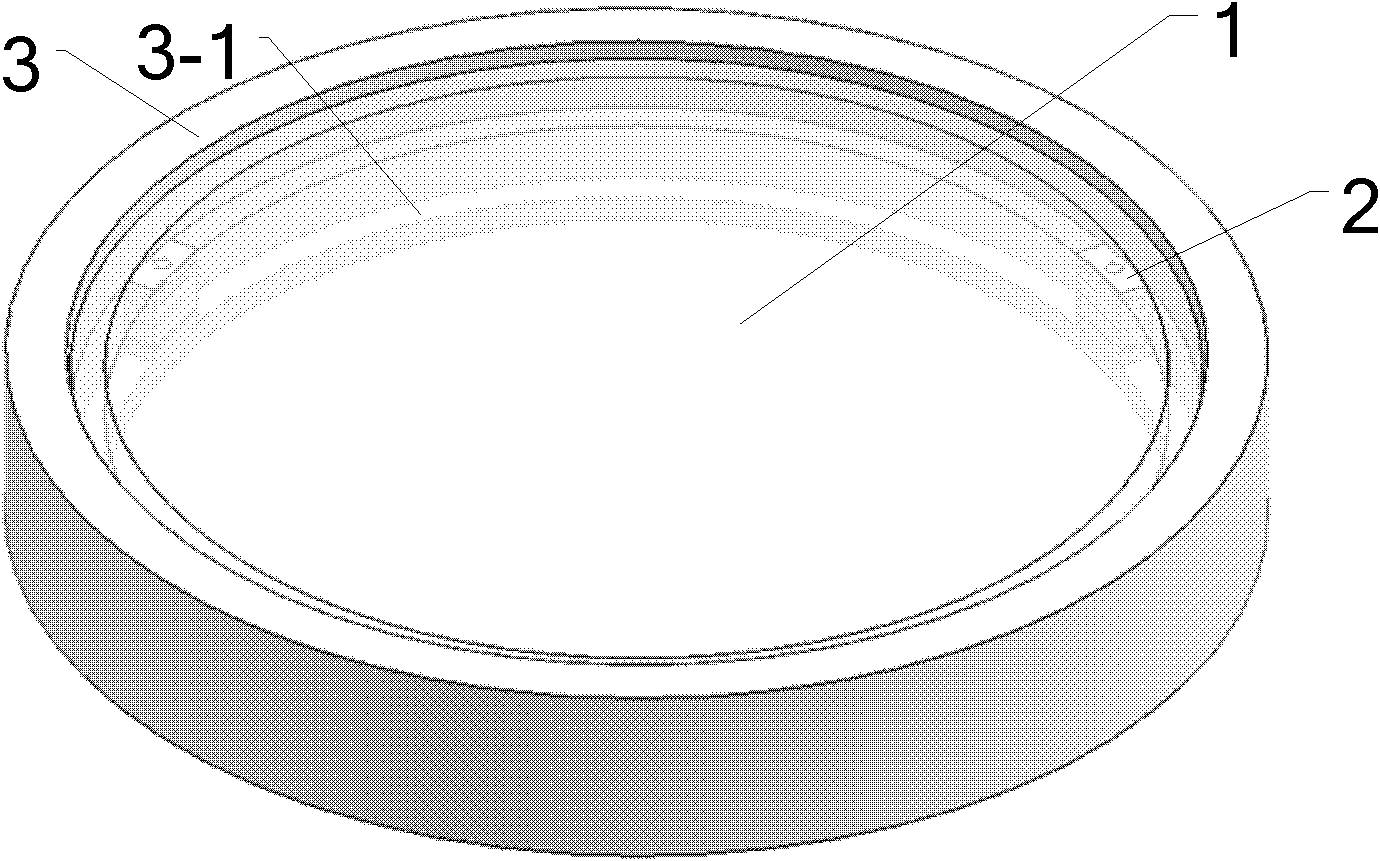

[0013] Specific implementation mode 1. Combination Figure 1 to Figure 4 Describe this embodiment, a kind of supporting device of eyeglass in lithographic projection objective lens, this device comprises support 2 and picture frame 3, lens 1 is supported in picture frame 3 by support 2, and described picture frame 3 is ring-shaped, in ring picture frame 3 A supporting part 3-1 is provided at the place where the bottom extends inwardly of the ring.

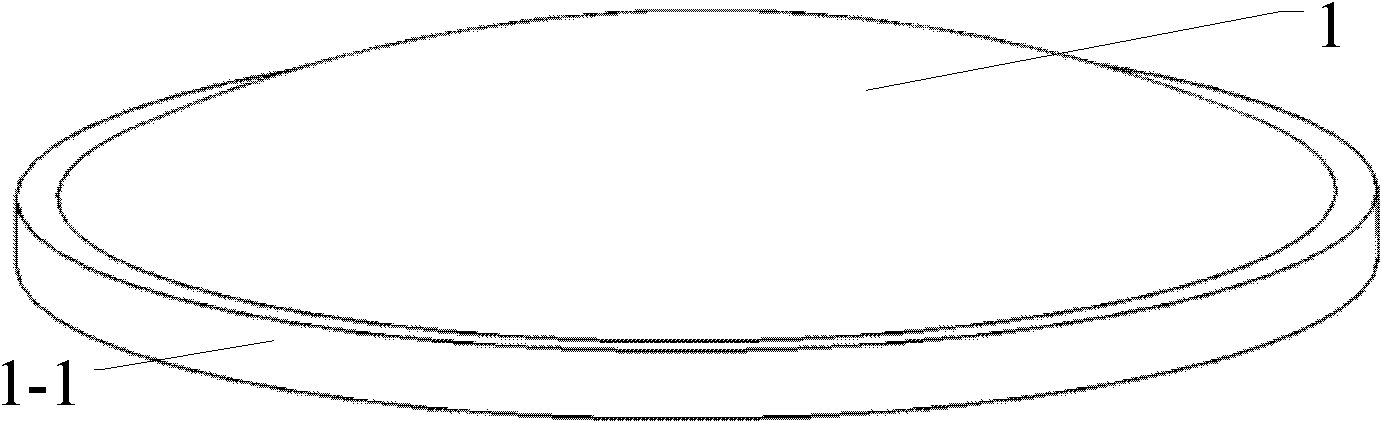

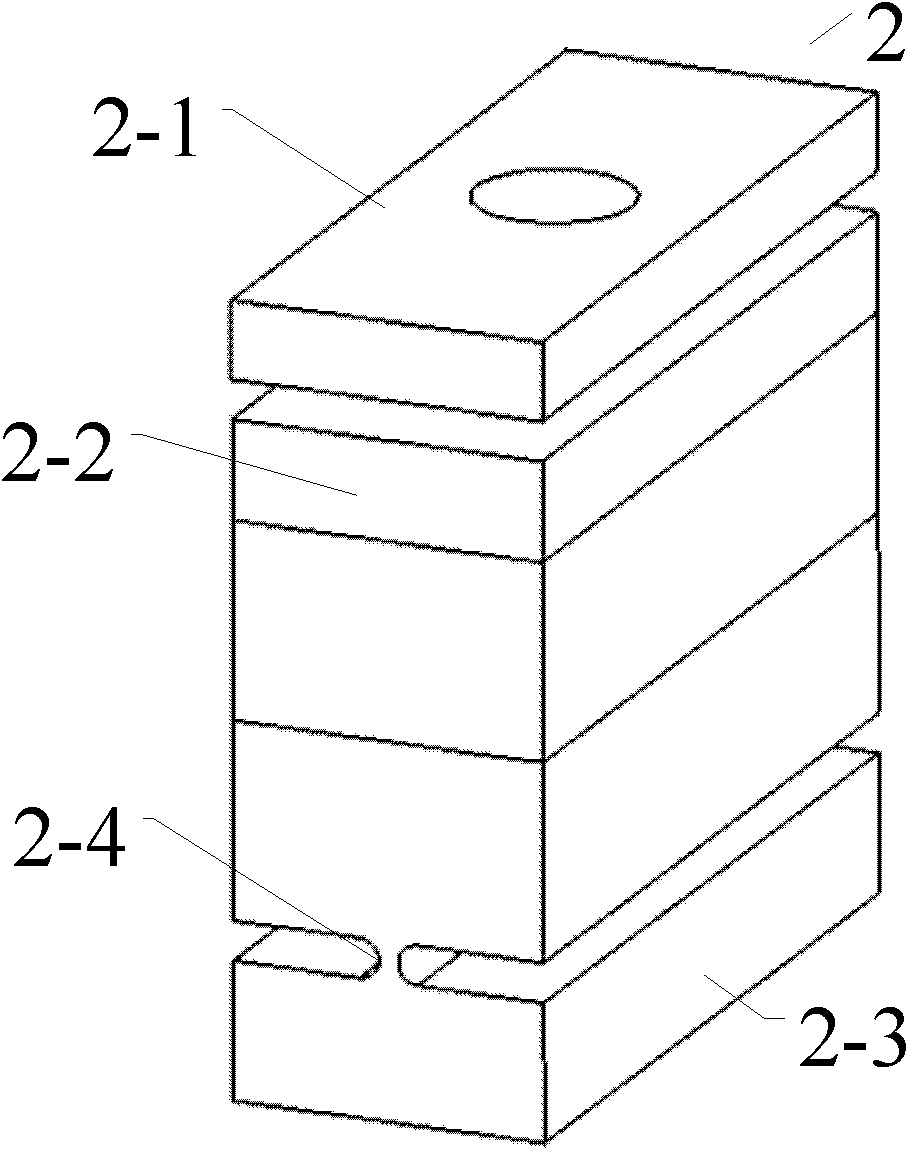

[0014] The lens 1 described in this embodiment is processed with a ring of flange flange 1-1 on the edge portion outside its clear aperture, and the upper and lower surfaces of the flange flange 1-1 are both flat, which is beneficial to the lens 1. Support positioning on support 2. The material of the lens 1 is fused silica or calcium fluoride commonly used in deep ultraviolet projection lithography objective lenses, and may also be common optical materials used in ordinary lenses. The lens 1 is fixed on the bearing block 2-1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com