Ball heat accumulator for steam and hot water

A technology of heat accumulator and steam-water separator, which is applied in the direction of preheating water accumulator, feed water heater, steam generation, etc., can solve the problems of large maintenance, large floor space, and high equipment investment, and achieve equipment safety. The effect of improving reliability, reducing labor intensity and simplifying system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

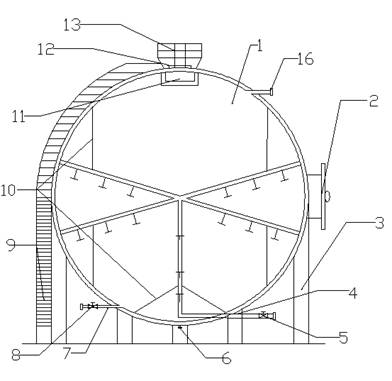

[0016] The invention discloses a Ball heat accumulator for steam and hot water , belonging to the field of steam utilization. Should Ball heat accumulator for steam and hot water The tank body is spherical, and a heat release device and a water supply and discharge device are installed inside the tank body. In addition, a three-ring nozzle device is also installed inside the tank body. In addition to the advantages of general spherical heat accumulators: large land utilization rate, small relative heat dissipation area, stable and safe structure, etc., this invention also has the characteristics of high steam-water mixing rate compared with previous heat accumulators, making the heat storage efficiency greatly increase.

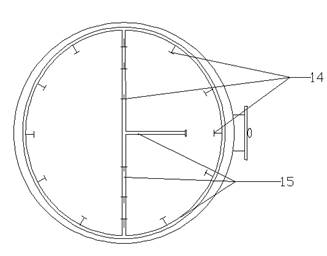

[0017] figure 1 It is a schematic diagram of the structure of the present invention. The external steam enters the interior of the heat accumulator through the steam inlet pipe 4, first passes through the semicircular steam pipe 12 in the three-rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com