Hydraulic rotary casing guide shoe

A technology of casing guiding shoes and rotating sleeves, which is applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of prolonging the cementing operation period, hindering the lowering of casing guiding shoes, and the lowering resistance of casing guiding shoes, and achieving Ease of popularization, simple structure, and the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

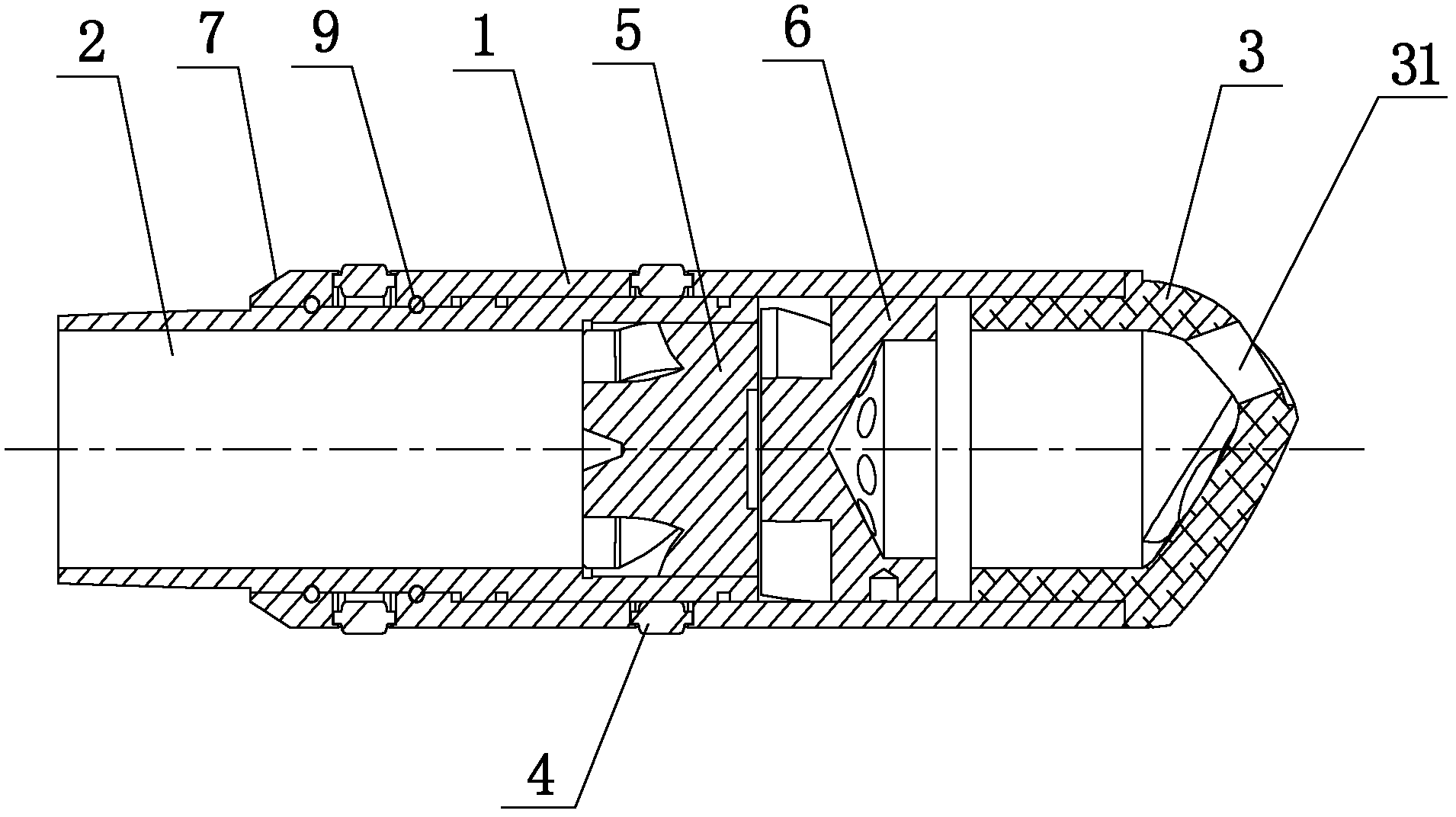

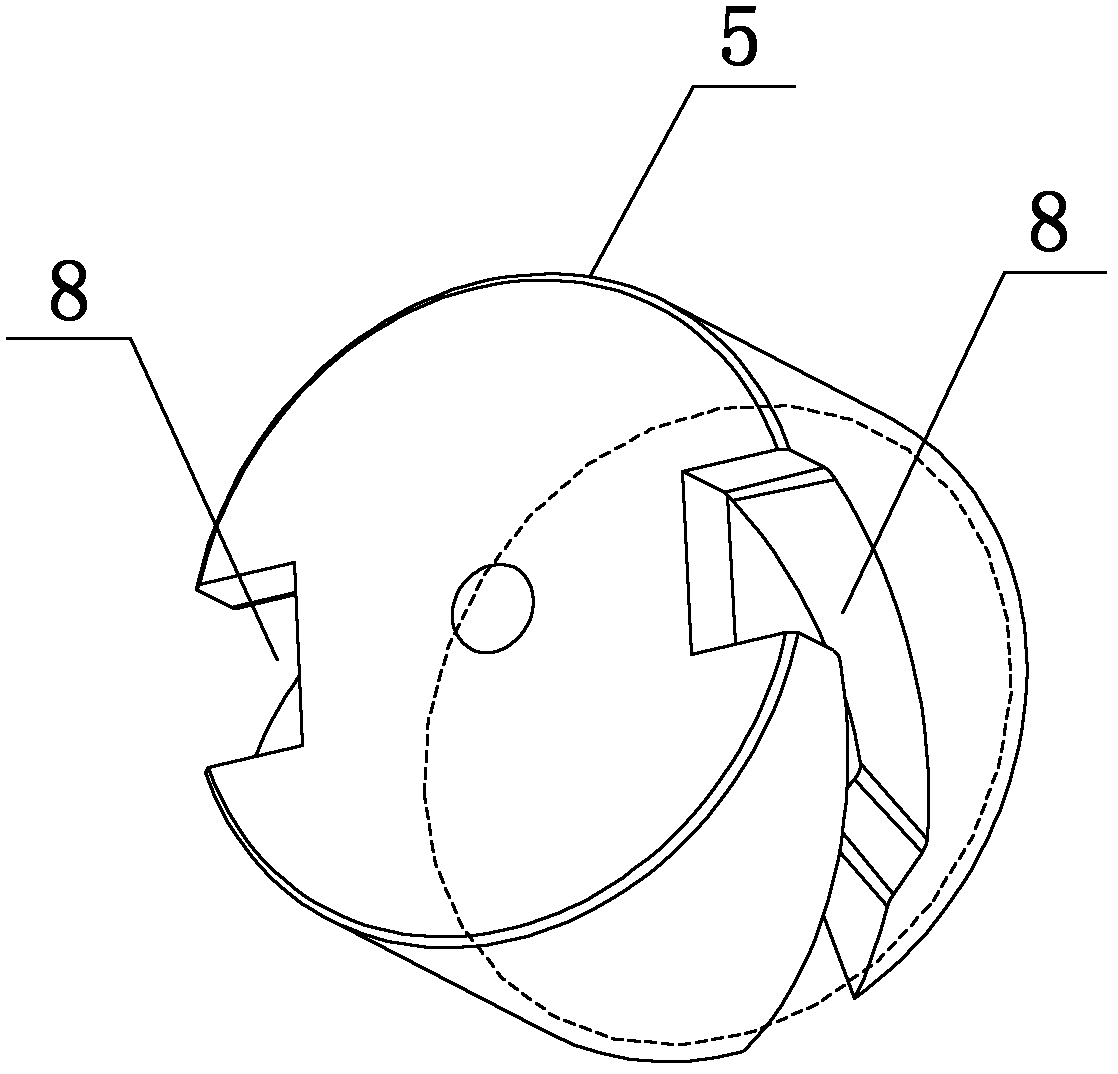

[0022] Such as figure 1 As shown, a hydraulic rotary casing guide shoe provided by the present invention includes a hollow suspension shell 1, a casing joint 2 is installed at the rear end of the suspension shell 1, and a hollow eccentric toe guide 3 is installed at the front end. , at the same time, in order to form a perfect matching relationship between the hydraulic rotating casing guide shoe and the casing, it is preferable to set the suspension outer casing 1 and the casing joint 2 in a circular tubular shape; the front end of the eccentric guide shoe head 3 is provided with an axial Eccentric hole 31, its end stretches in the cavity of suspension shell 1 inside, and the end of eccentric guide toe cap 3 is also provided with a plurality of through holes, and a plurality of through holes on the end of eccentric guide toe cap 3 are all connected with the inside The cavities are connected, and the rotating sleeve guide shoe also includes a rotating shaft 5 and a rotating sl...

Embodiment 2

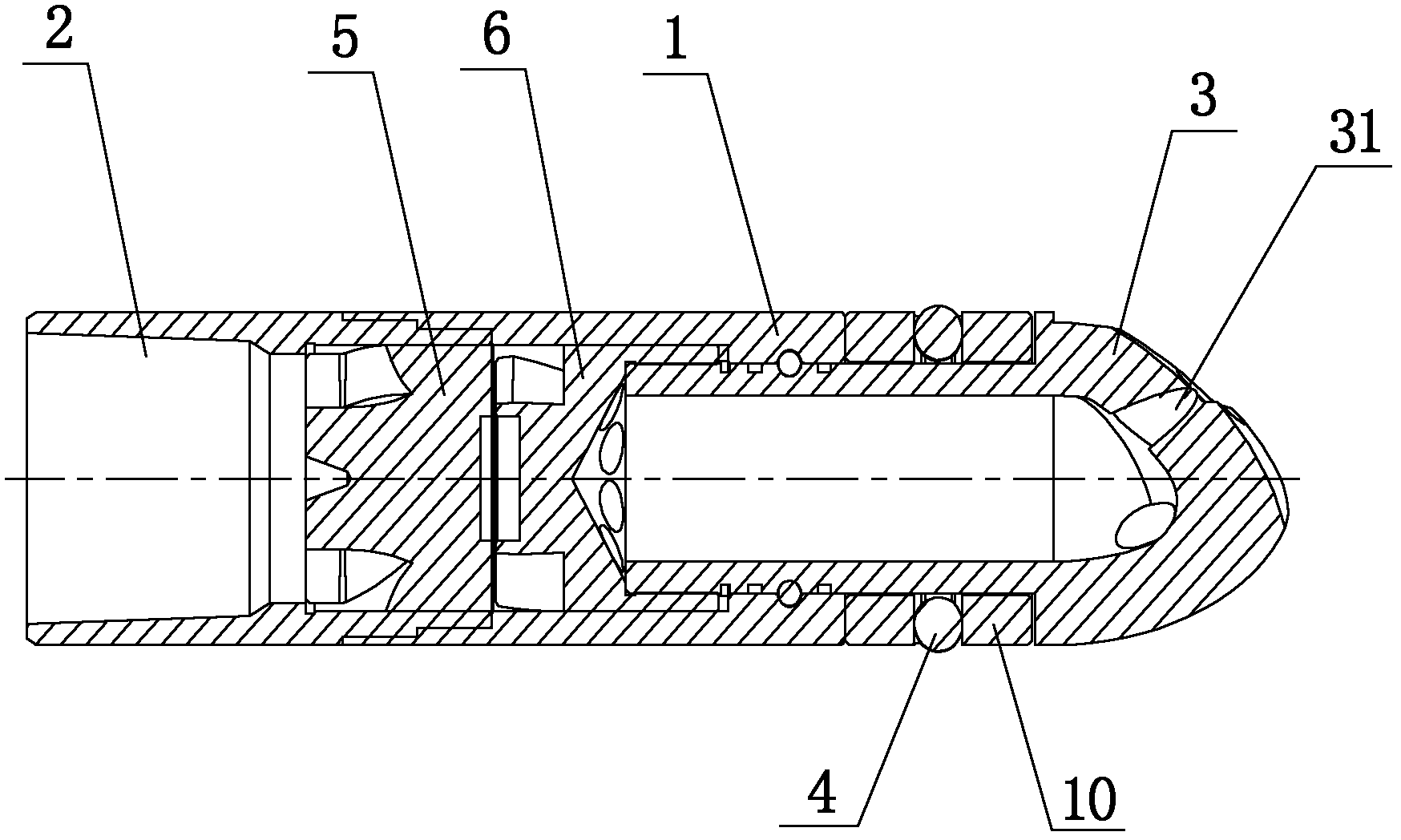

[0028] Such as figure 2 As shown, a hydraulic rotary casing guide shoe provided by the present invention includes a hollow suspension shell 1, a casing joint 2 is installed at the rear end of the suspension shell 1, and a hollow eccentric toe guide 3 is installed at the front end. , at the same time, in order to make the hydraulic rotary casing shoe and the casing form a perfect matching relationship, the suspension shell 1 and the casing joint 2 are both in the shape of a circular tube; the front end of the eccentric shoe head 3 is provided with an axial eccentric Hole 31, its end stretches in the cavity of hanging shell 1 inside, and the end of eccentric guide toe cap 3 is also provided with a plurality of through holes, and the plurality of through holes on the end of eccentric guide toe cap 3 are all connected with the inside. The cavities are connected, and the said rotating sleeve guide shoe also includes a rotating shaft 5 and a rotating sleeve 6, both of which are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com