A construction method of collapsible loess foundation

A technology of collapsible loess and construction method, which is applied in the fields of soil protection, foundation structure engineering, foundation structure test, etc. It can solve problems such as poor economy, single filling, unsatisfactory soil compaction effect between piles, etc., and achieve economical Significant benefits, shortening the pile length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

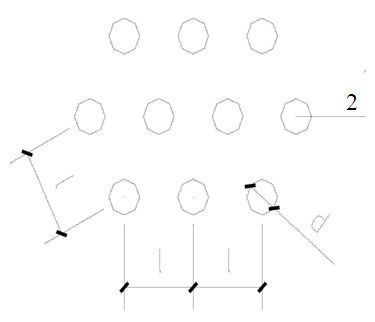

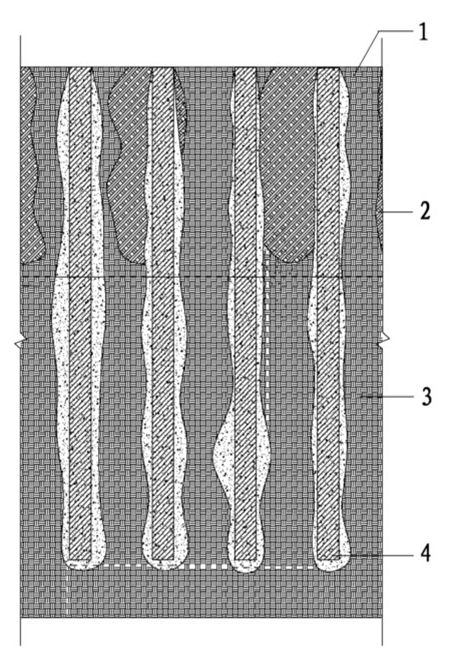

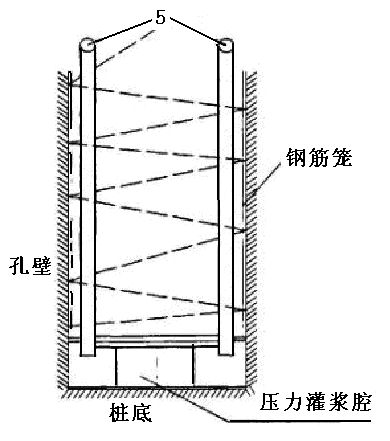

[0049] Super Down-hole Dynamic Compaction (Super Down-hole Dynamic Compaction, referred to as SDDC), which uses the mechanism of high kinetic energy, super pressure, and strong compaction to form holes through impact, from deep to shallow, and form piles layer by layer , In the process of overpressure kinetic energy dynamic compaction, a large dynamic passive earth pressure is generated on the side of the soil between the piles, forcing the filler to compact and extrude downward and around, so that the physical and mechanical indicators of the soil between the piles are fully improved. It can be widely used in the treatment of various special foundations such as miscellaneous filling, liquefaction, weak subsidence, and expansion. This method has the advantages of strong adaptability, large treatment depth, good treatment effect, environmental protection, little impact on the environment, and good economic benefits. It has been gradually recognized by people in recent years, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com