Steel anti-vibration block

A technology of section steel and block, which is applied in bridge erection/assembly, bridge maintenance, bridge reinforcement, etc. It can solve problems such as inconvenient installation of beams and slabs, secondary pouring of block, narrow construction space of block, etc., and achieves convenient maintenance and convenient construction. The effect of simplicity and beautiful structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

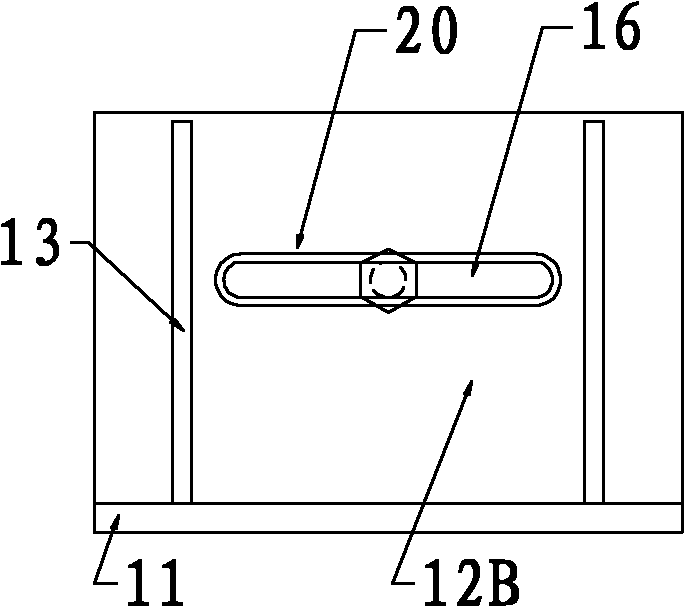

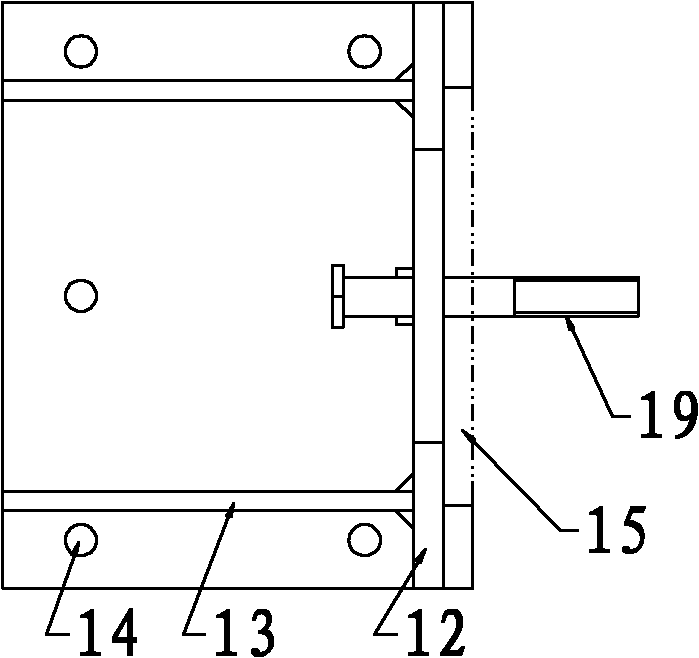

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the steel anti-vibration block of the present invention is used as the anti-vibration position-limiting structure.

[0038] On the cover beam or cap beam 2 of the bridge, a support pad stone 21 is arranged, and the beam body 3 of the bridge is connected to the support pad stone 21 through the support 4, and the support pad stone 21 is provided with a pre-embedded plate 22 and a ground Anchor bolts 5, the section steel anti-vibration block 1 is welded by section steel, including a base plate 11 and a baffle plate 12 fixedly connected to the base plate 11, the base plate 11 is provided with mounting holes 14, and the anchor bolts 5 connect the base plate 11 and the pre-installed The buried plate 22 is fixedly connected, and a limiting hole 16 is opened on the baffle plate 12. On the inner side of the baffle plate 12B, a ring-shaped reinforcing backing plate 20 is arranged around the limiting hole 16, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com