A transfer paper for sublimation inkjet printing

A technology of inkjet printing and transfer paper, which is applied in papermaking, paper coating, coated paper base paper, etc. It can solve problems such as deformation and warping, transfer failure, transfer image misalignment, etc., and achieve good absorbency and Quick drying, high image color saturation, and good image reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

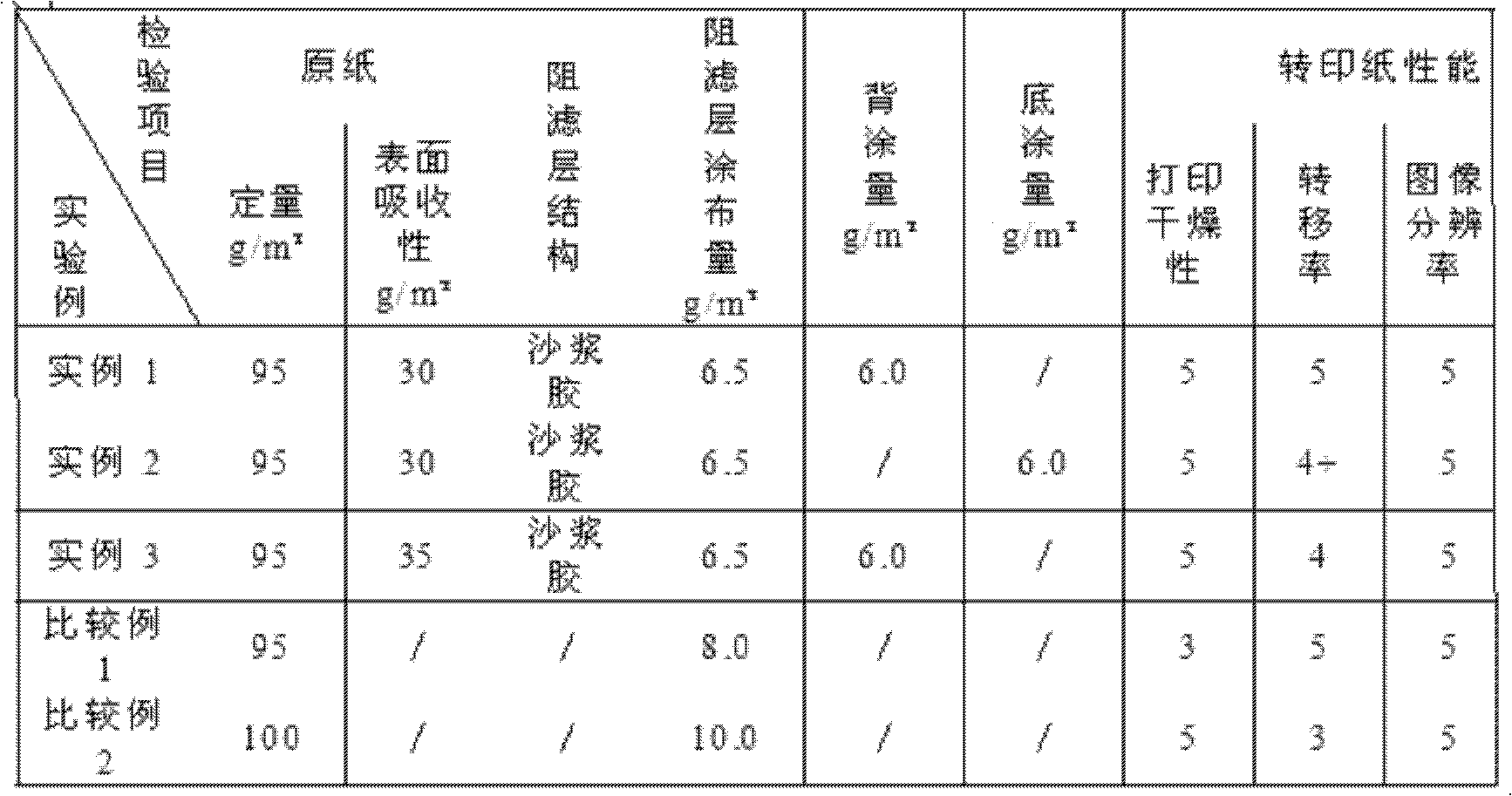

Examples

Embodiment

[0017] Embodiment: The base paper used in the present invention is single-sided glossy paper with bleached wood pulp as the main component. Single-sided glossy paper has good shape stability. Base paper weight is 60-100g / m 2 Preferably, the surface absorption weight is not more than 35g / m 2 (GB1540).

[0018] The smooth side of the base paper is coated with a filter-resistant layer, which is mainly composed of polyvinyl alcohol (hereinafter referred to as PVA), carboxymethyl fiber (hereinafter referred to as CMC) and epichloroenol polyamide cationic resin (hereinafter referred to as PAE) ) and polydiallyldimethylammonium chloride (hereinafter referred to as PDM) are composed of micropolymers formed by the reaction, and the filter resistance layer has a "mortar glue structure". Since the micropolymers are distributed on the surface of the filter-resistance layer, the specific surface area of the filter-resistance layer is significantly increased, thereby effectively improv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com