A kind of super imitation cotton polyester filament and its production process

A cotton polyester and filament technology, used in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of skyrocketing cotton prices and reduction of planting land, and achieve high stretching ratio and excellent quick-drying properties. , The crystallinity is smooth and soft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of production technology of super imitation cotton polyester filament, realizes by following steps:

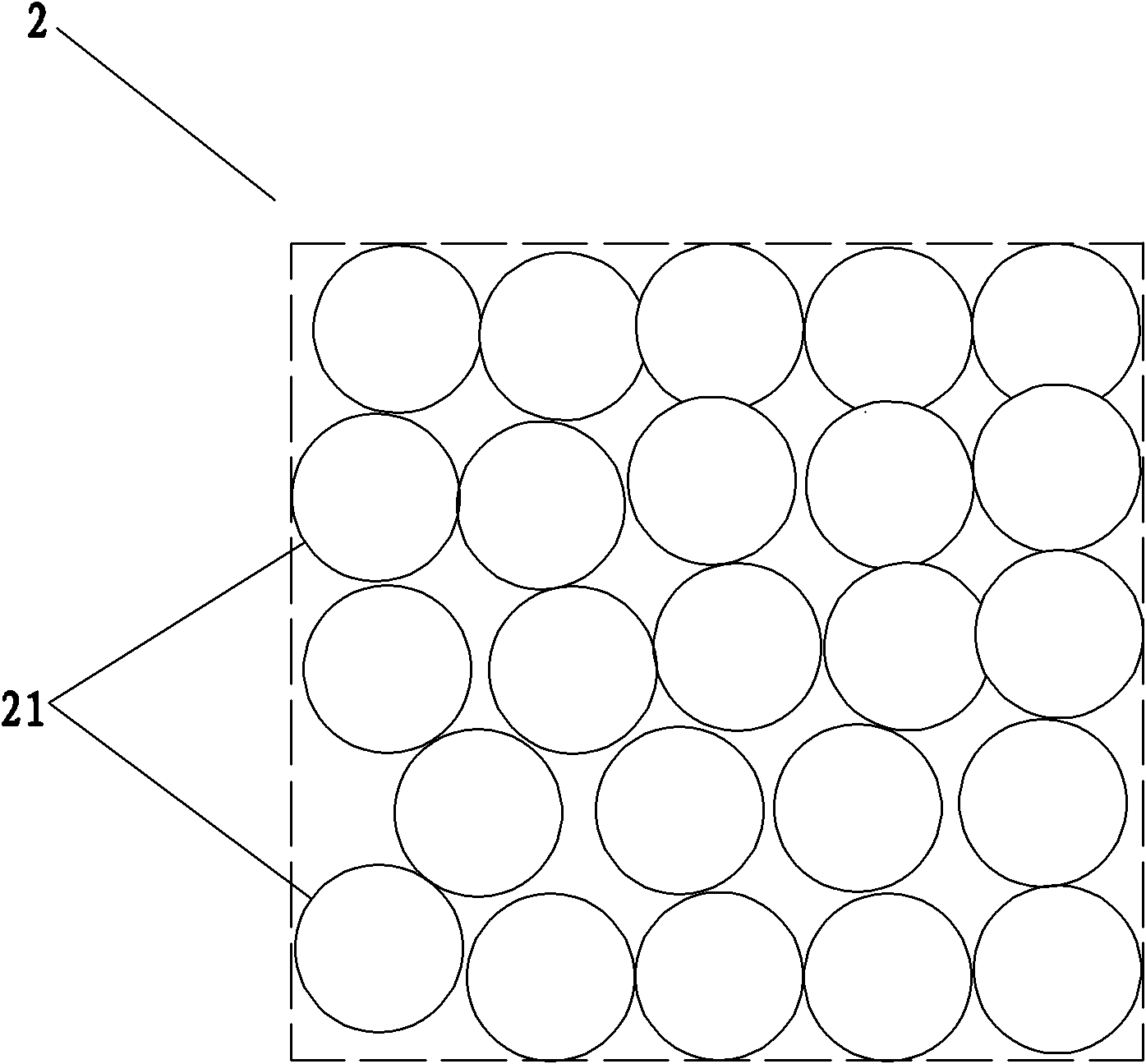

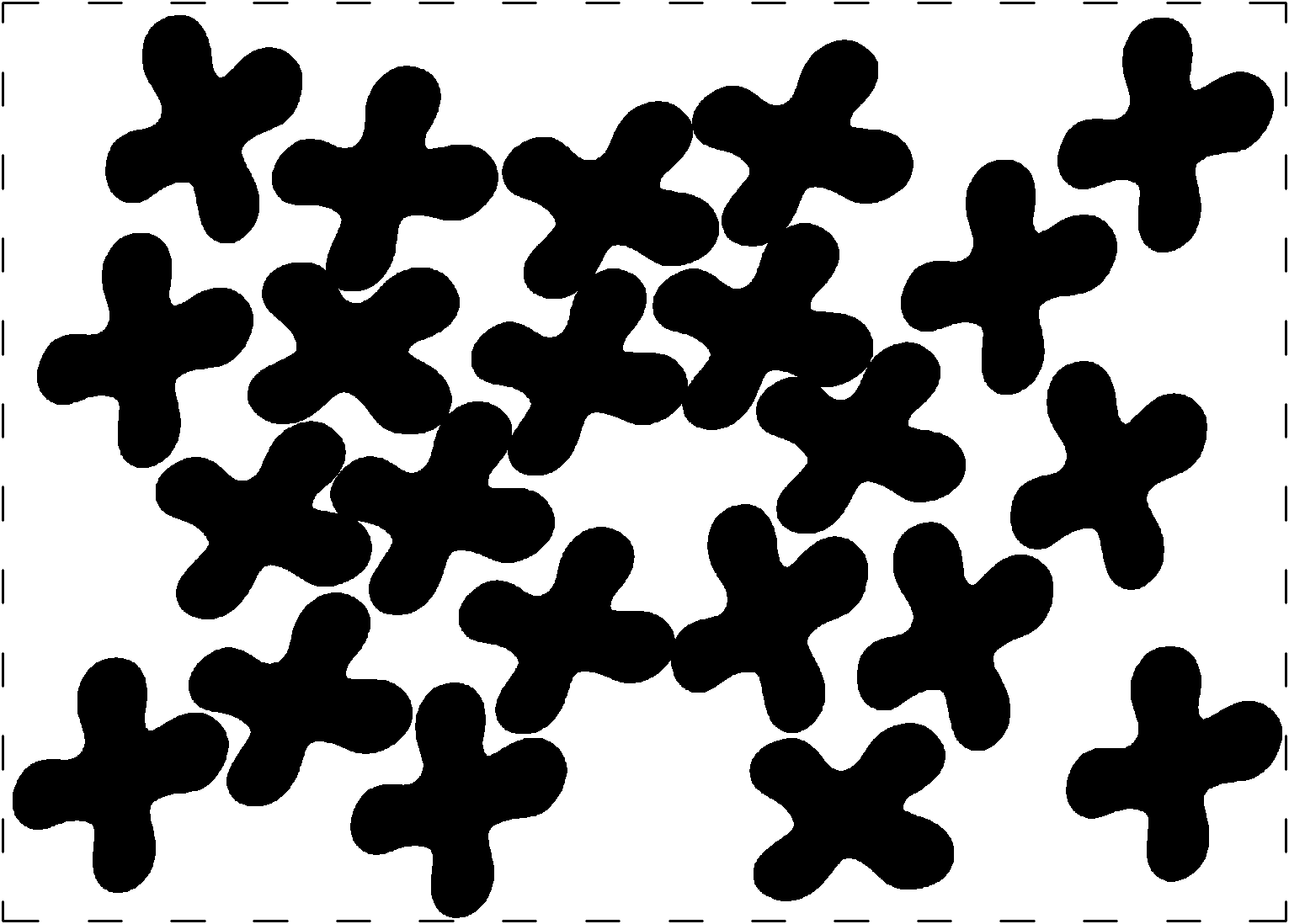

[0029] 1) Select raw materials: select a required polyester FDY silk 1 and superfine polyester POY silk 2, wherein the polyester FDY silk 1 is a semi-dull polyester FDY silk, and the fineness of the semi-dull polyester FDY silk 2 is 1.25D. The elongation at break is 28%. The semi-dull polyester FDY yarn is a tow composed of several monofilaments, and the cross-sectional shape of the monofilament is cross-shaped; , the fineness of the full-dull superfine polyester POY yarn is 0.64D, and the elongation at break is 115%. The full-dull superfine polyester POY yarn is a tow composed of several monofilaments. is round;

[0030] 2) The above-mentioned semi-dull polyester FDY yarn and the above-mentioned full-dull superfine polyester POY yarn are plied to form a plied yarn;

[0031] 3) False twist deformation processing: the above-mentioned plied yarn passes through th...

Embodiment 2

[0033] A kind of production technology of super imitation cotton polyester filament, realizes by following steps:

[0034]1) Select raw materials: select a required polyester FDY silk 1 and superfine polyester POY silk 2, wherein the polyester FDY silk 1 is a semi-dull polyester FDY silk, and the semi-dull polyester FDY silk 2 has a fineness of 0.9D, The elongation at break is 30%. The semi-dull polyester FDY yarn is a tow composed of several monofilaments, and the cross-sectional shape of the monofilament is cross-shaped; , the fineness of the full-dull superfine polyester POY yarn is 0.73D, and the elongation at break is 110%. The full-dull superfine polyester POY yarn is a tow composed of several monofilaments. The cross-sectional shape of the monofilament is round;

[0035] 2) The above-mentioned semi-dull polyester FDY yarn and the above-mentioned full-dull superfine polyester POY yarn are plied to form a plied yarn;

[0036] 3) False twist deformation processing: the a...

Embodiment 3

[0038] A kind of production technology of super imitation cotton polyester filament, realizes by following steps:

[0039] 1) Select raw materials: select one strand of required polyester FDY silk 1 and superfine polyester POY silk 2, wherein the polyester FDY silk 1 is a semi-dull polyester FDY silk, and the fineness of the semi-dull polyester FDY silk 2 is 1.2D. The elongation at break is 30%. The semi-dull polyester FDY yarn is a tow composed of several monofilaments, and the cross-sectional shape of the monofilament is cross-shaped; , the fineness of the full-dull superfine polyester POY yarn is 0.89D, and the elongation at break is 120%. The full-dull superfine polyester POY yarn is a tow composed of several monofilaments. The cross-sectional shape of the monofilament is round;

[0040] 2) The above-mentioned semi-dull polyester FDY yarn and the above-mentioned full-dull superfine polyester POY yarn are plied to form a plied yarn;

[0041] 3) False twist deformation pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com