Ganoderma ginkgo ginkgo rice wine, preparation method and efficacy thereof

A technology of ginkgo and ganoderma lucidum, applied in the field of bioengineering, can solve the problems of restricting the sales of ginkgo wine, the use of ginkgo liquor or fruit wine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

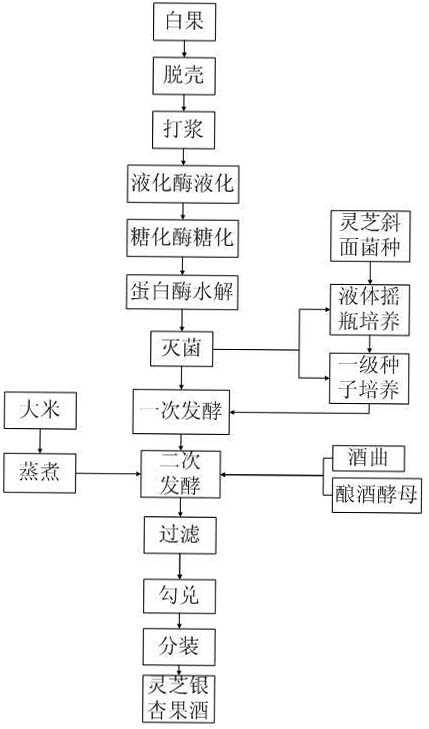

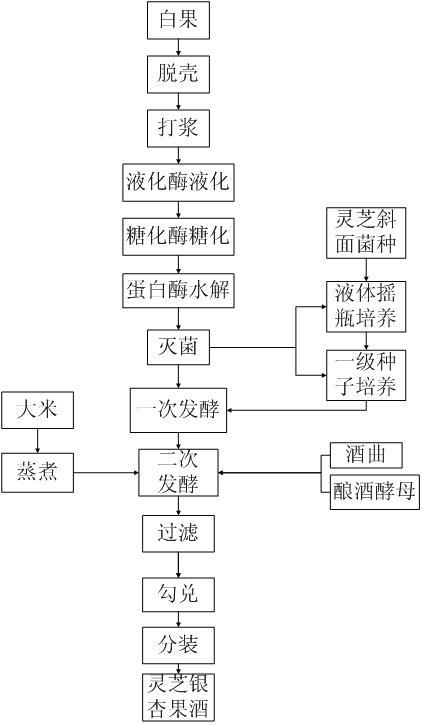

Method used

Image

Examples

Embodiment 1

[0019] Accurately weigh 200g of shelled ginkgo fruit, add 200mL of water to the pulp, boil and gelatinize, and lower the temperature to 60°C, add 0.4mL of liquefied enzyme (Wuxi Saide Biological Engineering Co., Ltd., 160,000 units / mL) to hydrolyze 50 at 60°C Minutes, cool down to 50°C, add 0.2mL glucoamylase (Wuxi Saide Biological Engineering Co., Ltd., 20,000 units / mL) for hydrolysis at 50°C for 50 minutes, cool down to 30°C, add 0.4g papain (Donghenghua Road, Nanning, Guangxi) Biotechnology Co., Ltd., 800,000 units / g), hydrolyzed for 9 hours to obtain ginkgo ginkgo hydrolyzate; the ginkgo ginkgo hydrolyzate was divided into 250mL triangular flasks, each bottle was 100mL, sterilized at 100°C for 60 minutes, and added to Ganoderma lucidum after cooling Test-tube slant strains were cultivated at 60 rpm and 22°C for 10 days to obtain strains in liquid shake flasks of Ganoderma lucidum; ginkgo hydrolyzate was sterilized at 100°C for 60 minutes, and then added to the liquid shaker...

Embodiment 2

[0022] Accurately weigh 200g of shelled ginkgo fruit, add 1000mL of water to the pulp, boil for gelatinization, cool down to 70°C, add 1.6mL of liquefied enzyme (Wuxi Saide Biological Engineering Co., Ltd., 160,000 units / mL) and hydrolyze for 30 minutes at 70°C. Cool down to 60°C, add 1.6mL glucoamylase (Wuxi Saide Biological Engineering Co., Ltd., 20,000 units / mL) for hydrolysis at 60°C for 30 minutes, cool down to 40°C, add 0.4g papain (Guangxi Nanning Donghenghuadao Biotechnology Co., Ltd. Co., Ltd., 800,000 units / g), hydrolyzed for 6 hours to obtain ginkgo ginkgo hydrolyzate; the ginkgo ginkgo hydrolyzate was divided into 250mL triangular flasks, each bottle was 100mL, sterilized at 110°C for 30 minutes, cooled and placed on the inclined surface of the ganoderma test tube The strains were cultured at 120 rpm and 28°C for 7 days to obtain the liquid shake flask strains of Ganoderma lucidum; the ginkgo hydrolyzate was sterilized at 110°C for 30 minutes, and the liquid shake f...

Embodiment 3

[0025] Accurately weigh 200g of shelled ginkgo fruit, make a pulp, add 2000mL of water, boil for gelatinization, cool down to 80°C, add 100mL of liquefied enzyme (Wuxi Saide Biological Engineering Co., Ltd., 160,000 units / mL) to hydrolyze at 80°C for 10 minutes, Cool down to 70°C, add 100mL glucoamylase (Wuxi Saide Biological Engineering Co., Ltd., 20,000 units / mL) for hydrolysis at 70°C for 10 minutes, cool down to 50°C, add 30g papain (Guangxi Nanning Donghenghuadao Biotechnology Co., Ltd. , 800,000 units / g), and hydrolyzed for 0.5 hours to obtain ginkgo biloba hydrolyzate; the shake flask culture process described therein is: the ginkgo ginkgo hydrolyzate is divided into 250mL triangular flasks, each bottle is 100mL, and sterilized at 120°C for 10 minutes , after cooling, insert the slant strain of ganoderma lucidum test tube, and cultivate it at a speed of 180 rpm and a temperature of 33°C for 5 days to obtain the strain of ganoderma lucidum liquid shake bottle; the ginkgo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com