Oil displacement method for high-temperature high-salt oil reservoir

An oil displacement method, a high-temperature and high-salt technology, which is applied in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of alkali corrosion, poor oil displacement efficiency, and high use concentration in ASP flooding. The effect of reducing interfacial tension, high salinity resistance, and enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

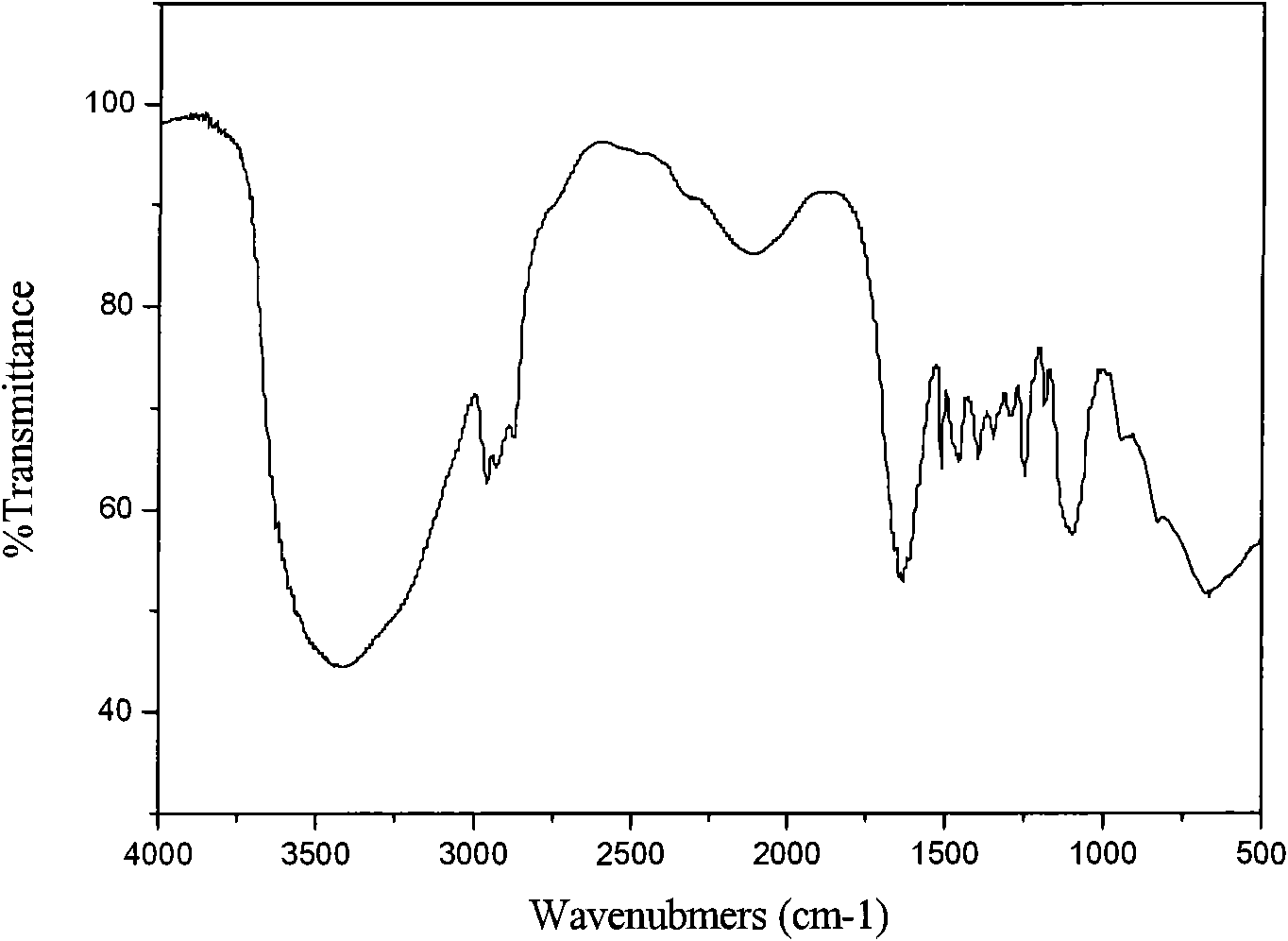

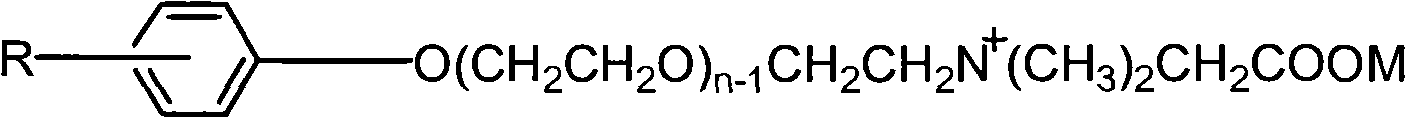

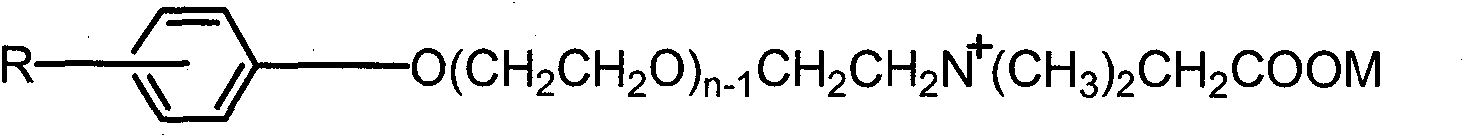

Method used

Image

Examples

Embodiment 1

[0030] 1) Synthesis of chloropentyl (R=5) phenol polyoxyethylene (n=2) ether

[0031] Add 100g of pentyl (R=5) phenol polyoxyethylene (n=2) ether and 57g of pyridine into a four-necked round-bottomed flask equipped with a reflux condensing device, a thermometer, a stirrer and a gas absorption device, and heat to 70 under stirring. °C, slowly add 85 g of thionyl chloride dropwise with a dropping funnel, and react at 90 °C for 10 hours after the dropwise addition is completed. After the reaction, the reactants were left to stand, cooled and separated into layers. The upper organic phase was the target product, and the lower layer was solid pyridinium hydrochloride. Use 30% sodium hydroxide solution to neutralize the upper organic phase to neutral or weakly alkaline, separate the inorganic salt, then wash the upper organic phase with hot saturated saline for 5 to 6 times, and obtain the intermediate product chlorine after drying. Substituent amyl (R=5) phenol polyoxyethylene (n=...

Embodiment 2

[0039] Synthesis of Nonyl (R=9) Phenol Polyoxyethylene Ether (n=10) Sodium Carboxylate Betaine

[0040] 1) Synthesis of Chlorinated Nonyl (R=9) Phenol Polyoxyethylene (n=10) Ether

[0041] Add 100g of nonyl (R=9) phenol polyoxyethylene (n=10) ether and 22g of pyridine into a four-neck round bottom flask equipped with a reflux condensing device, a thermometer, a stirrer and a gas absorption device, and heat to 70 32.5 g of thionyl chloride was slowly added dropwise with a dropping funnel, and reacted at 70°C for 8 hours after the dropwise addition was completed. After the reaction, the reactants were left to stand, cooled and separated into layers. The upper organic phase was the target product, and the lower layer was solid pyridinium hydrochloride. Use 30% sodium hydroxide solution to neutralize the upper organic phase to neutral or weakly alkaline, separate the inorganic salt, then wash the upper organic phase with hot saturated saline for 5 to 6 times, and obtain the inter...

Embodiment 3

[0049] Synthesis of Sodium Carboxylate Betaine of Dodecylphenol Polyoxyethylene Ether (n=20)

[0050] 1) Synthesis of chlorinated dodecylphenol polyoxyethylene (n=20) ether

[0051] Add 100g of dodecylphenol polyoxyethylene (n=20) ether and 13g of pyridine into a four-neck round bottom flask equipped with a reflux condensing device, a thermometer, a stirrer and a gas absorption device, heat to 60°C under stirring, and use 18.7 g of thionyl chloride was slowly added dropwise into the dropping funnel, and reacted at 80° C. for 10 hours after the dropwise addition was completed. After the reaction, the reactants were left to stand, cooled and separated into layers. The upper organic phase was the target product, and the lower layer was solid pyridinium hydrochloride. Use 30% sodium hydroxide solution to neutralize the upper organic phase to neutral or weakly alkaline, separate the inorganic salt, then wash the upper organic phase with hot saturated saline for 5 to 6 times, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com