Rigid polyvinyl chloride (PVC) injection molding material

A hard and stabilizer technology, applied to rigid pipes, mechanical equipment, pipes/pipe joints/fittings, etc., to achieve good corrosion resistance, broad application prospects, high mechanical strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical characteristics of the present invention will be further elaborated below in conjunction with specific embodiments.

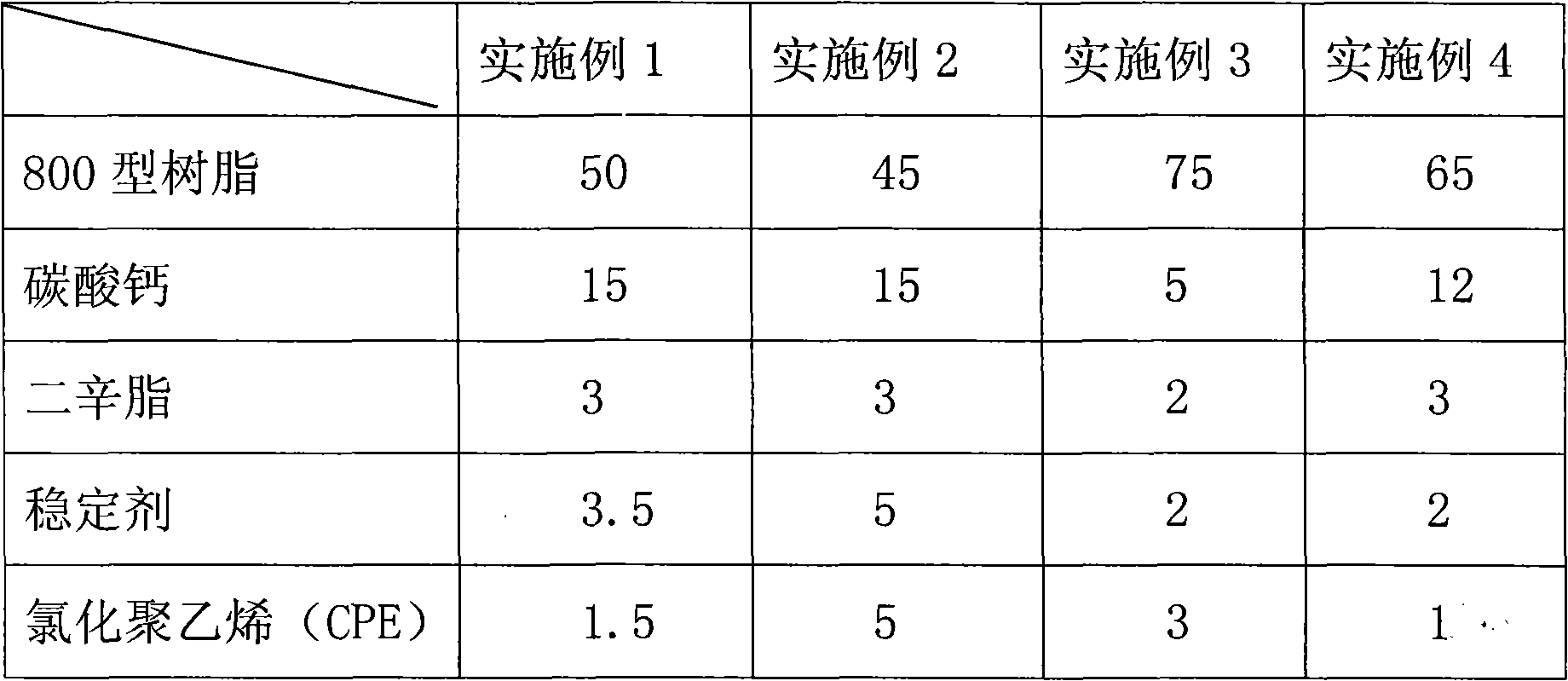

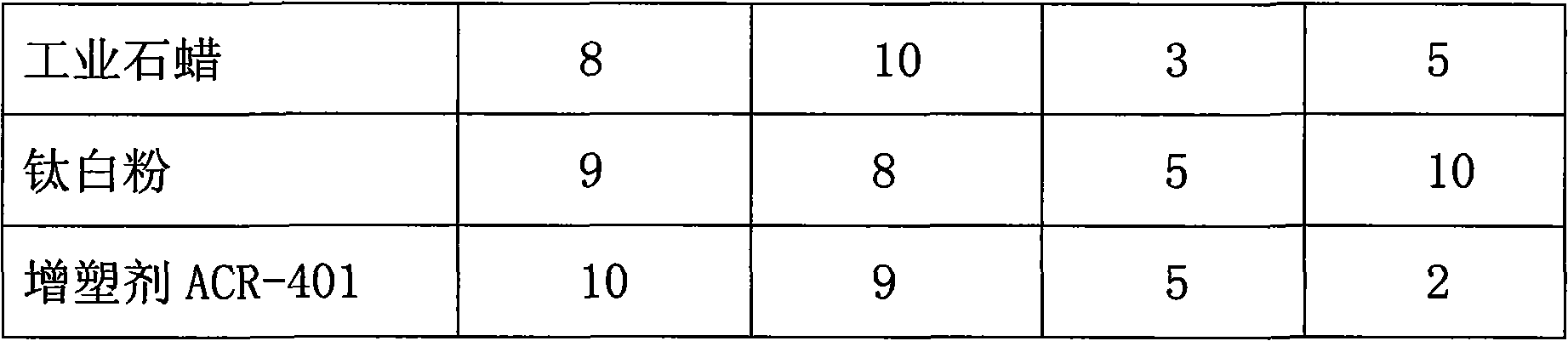

[0021] Weigh according to the content of the raw material components listed in Table 1, add it into the mixer, and transfer it to the cold roll when it is mixed to about 110 degrees.

[0022]

[0023]

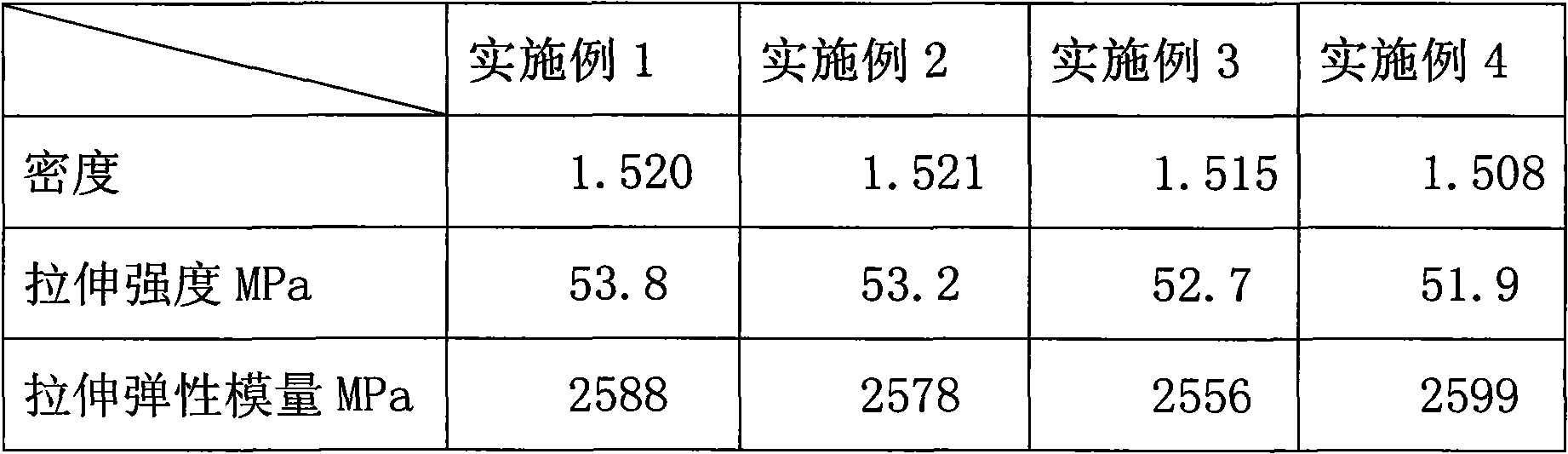

[0024] Table 2 is the performance parameters of the pipe made of this injection molding material:

[0025]

[0026] Density is GB / T 1033-1986 Plastic Density and Relative Density Test Method. Tensile strength and tensile modulus of elasticity are determined by GB / T8804.2-2003 thermoplastic pipe tensile properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com