A kind of bamboo shoot shell fiber/PE degradable composite material and preparation method thereof

A composite material and bamboo shoot shell technology, applied in the field of bamboo shoot shell fiber/PE degradable composite material and its preparation, can solve problems such as environmental pollution, fresh bamboo shoot shell rot, etc., to solve environmental pollution problems, increase added value, and improve production process simple clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

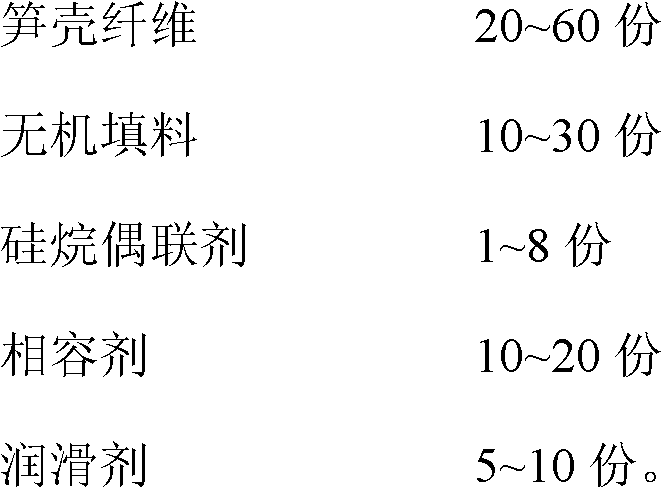

Method used

Image

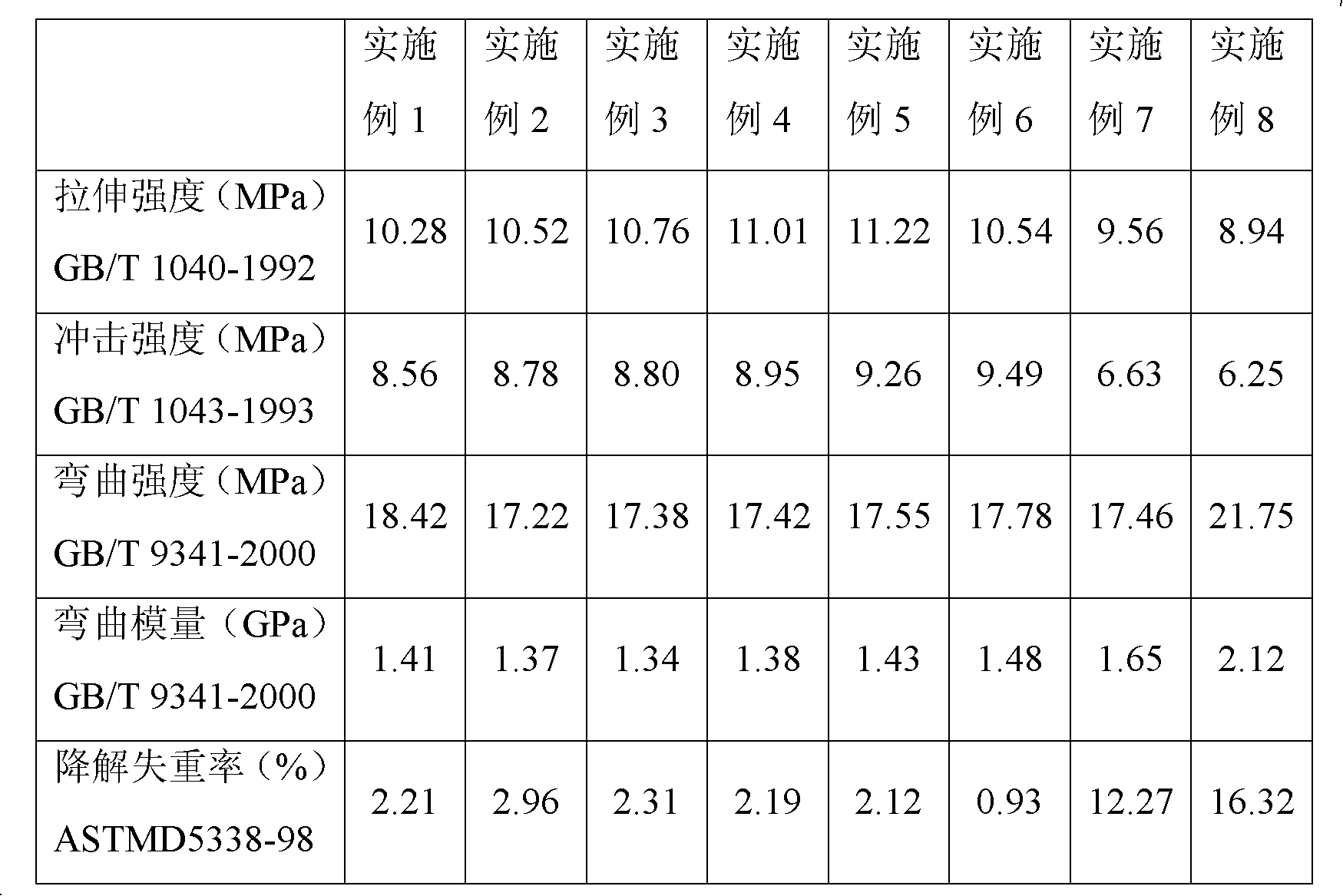

Examples

Embodiment 1

[0028] 30 parts of bamboo shoot shell powder (average particle size 40 mesh, water content less than 2%) and 1.0 part of silane coupling agent KH-550 were mixed at 100°C for 5 minutes, and the bamboo shoot shell powder was modified to make the silane coupling agent fully Evenly distribute on the surface of bamboo shoot shell powder.

[0029] Disperse the above-mentioned bamboo shoot shell fiber, 70 parts of PE, 10 parts of polyacrylate, 5 parts of simethicone, 10 parts of talc powder and functional additives in a high-speed kneader at a speed of 1000 rpm, at a temperature of 60 °C and for 10 minutes to produce premix.

[0030] The above-mentioned premixed material is granulated by a twin-screw extruder and extruded through a mold. The screw speed of the extruder is 200rpm, the temperature of the barrel is 170°C, the temperature of the mold is 160°C, and the exhaust vacuum negative pressure is -0.08Mpa. The bamboo shoot shell fiber / PE degradable composite material is obtained....

Embodiment 2

[0033] 30 parts of bamboo shoot shell powder (average particle size 50 mesh, water content less than 2%) and 1.0 part of silane coupling agent KH-560 were mixed at 100°C for 5 minutes, and the bamboo shoot shell powder was modified to make the silane coupling agent fully Evenly distribute on the surface of bamboo shoot shell powder.

[0034] Disperse the above-mentioned bamboo shoot shell fiber, 70 parts of PE, 15 parts of maleic anhydride modified polypropylene, 6 parts of polyethylene wax, 15 parts of talc powder and functional additives in a high-speed kneader at a speed of 800 rpm, a temperature of 55°C, and a time of 15 minutes , to make a premix.

[0035] The above premixed material is granulated by a twin-screw extruder and extruded through a mold. The screw speed of the extruder is 180rpm, the barrel temperature is 180°C, the mold temperature is 170°C, and the exhaust vacuum negative pressure is -0.05Mpa. The bamboo shoot shell fiber / PE degradable composite material w...

Embodiment 3

[0037] 30 parts of bamboo shoot shell powder (average particle size 60 mesh, water content less than 2%) and 1.0 part of silane coupling agent KH-570 were mixed at 100°C for 5 minutes, and the bamboo shoot shell powder was modified to make the silane coupling agent fully Evenly distribute on the surface of bamboo shoot shell powder.

[0038] Disperse the above-mentioned bamboo shoot shell fiber, 70 parts of PE, 18 parts of chlorinated polyethylene, 8 parts of paraffin, 18 parts of calcium carbonate and functional additives in a high-speed kneader at a speed of 1200 rpm, a temperature of 60 ° C, and a time of 8 minutes to make a premix material.

[0039] The above premixed material is granulated by a twin-screw extruder and extruded through a mold. The screw speed of the extruder is 190rpm, the barrel temperature is 150°C, the mold temperature is 180°C, and the exhaust vacuum negative pressure is -0.06Mpa. The bamboo shoot shell fiber / PE degradable composite material was obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com